Packaging body of polyvinyl alcohol film roll

A packaging body and film technology, applied in packaging, transportation and packaging, containers to prevent mechanical damage, etc., can solve the problems of low productivity and easy cutting of polarizing film polarizers, and achieve the goal of preventing and inhibiting injuries. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

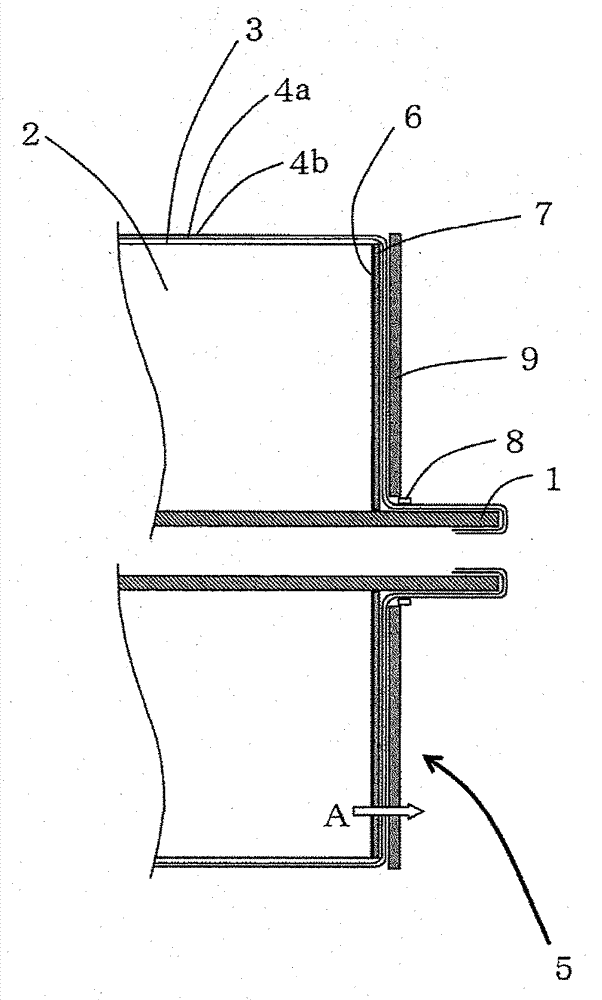

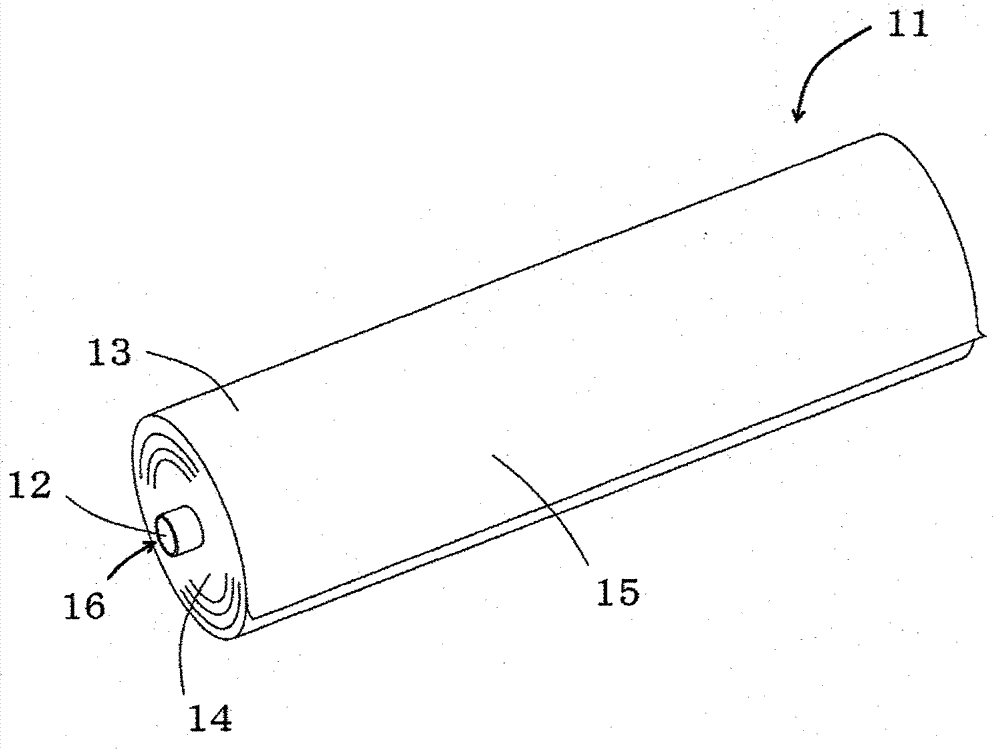

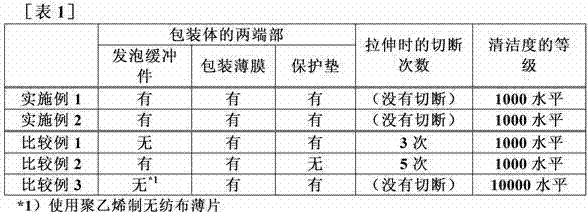

[0096] (1) A PVA film with a width of 400 cm, a thickness of 75 μm, and a length of 10,000 m (the degree of polymerization of PVA is 2400, the degree of saponification of PVA is 99.9 mol%, the content of glycerin is 11% by mass, and the moisture content is 4.0% by mass) is wound up to a length of 450 cm and a diameter of 6 Inch cylindrical aluminum core to get rolls. At this time, the core was wound up so that the core protruded 25 cm from each end surface of the roll. The resulting roll had a diameter of 115 cm. Visually observing the end surface and outer peripheral surface of the roll, no damage was observed.

[0097] (2) On both end faces of the above-mentioned roll, as foam cushioning materials, one foamed polyethylene sheet with a thickness of 5 mm was cut out in accordance with the shape of the end faces of the roll. The foamed polyethylene sheet is an independent cell type with an expansion ratio of 10 times, and the water absorption rate is 0.01g / cm 2 , 25% compres...

Embodiment 2

[0108] (1) A PVA film with a width of 440 cm, a thickness of 60 μm, and a length of 12,500 m (the degree of polymerization of PVA is 2400, the degree of saponification of PVA is 99.9 mol%, contains 11% by mass of glycerin, and the moisture content is 4.0% by mass) is wound up to a length of 480 cm and a diameter of 6 Inch cylindrical iron core to get rolls. At this time, the core was wound up so that the core protruded 20 cm from each end surface of the roll. The resulting roll had a diameter of 122 cm. Visually observing the end surface and outer peripheral surface of the roll, no damage was observed.

[0109] (2) On both end faces of the above-mentioned roll, as foam cushioning materials, one foamed polyethylene sheet with a thickness of 10 mm was cut out in accordance with the shape of the end faces of the roll. The foamed polyethylene sheet is an independent cell type with an expansion ratio of 20 times, and the water absorption rate is 0.03g / cm 2 , 25% compressive stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com