Process for producing fermented malt drink

Technology of a kind of malt beverage, manufacturing method, applied in the field of fermented malt beverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

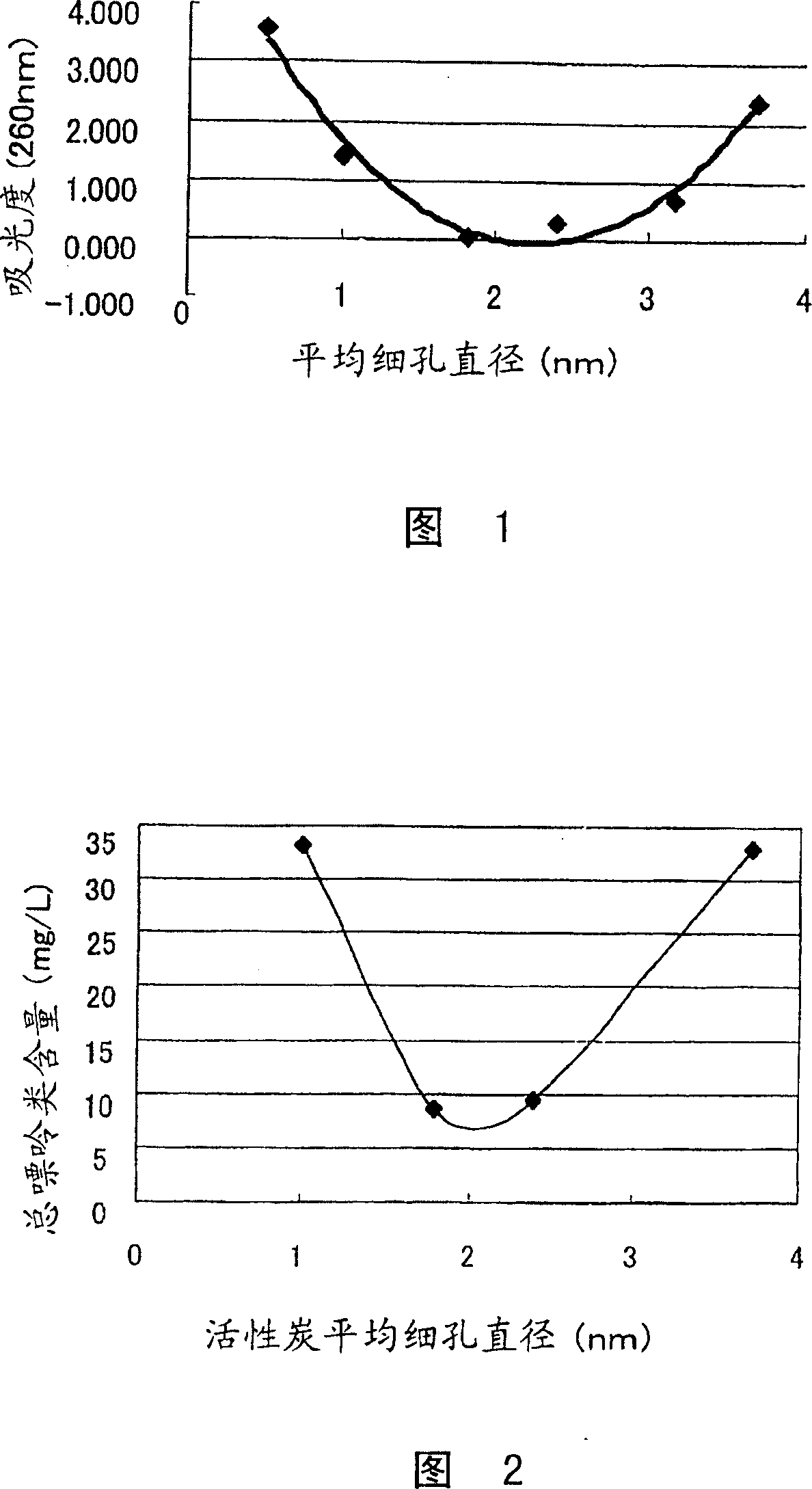

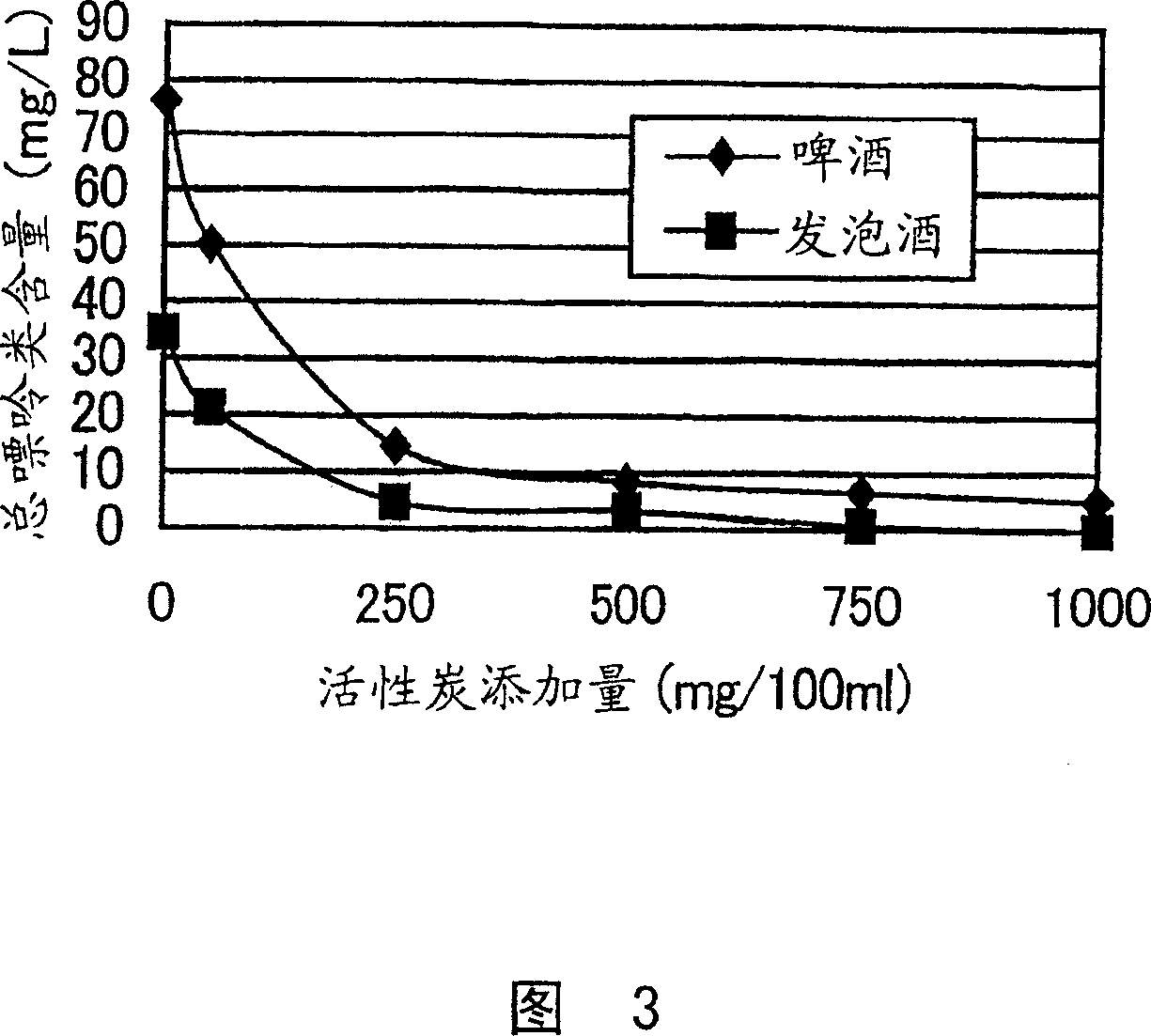

[0012] The present invention involves selectively adsorbing and removing purine compounds using an adsorbent for selectively adsorbing purine compounds in the production process of fermented malt beverages such as beer and sparkling wine. Activated carbon can be used as an adsorbent for selectively adsorbing purine compounds, and particularly, an adsorbent having an average pore diameter of 1 to 3.5 nm can be effectively used.

[0013] In the present invention, in the production process of the fermented malt beverage, in the production process of the fermented malt beverage after the feeding process, treatment is performed with an adsorbent that selectively adsorbs purine compounds. As the treatment method for the adsorbent, column treatment or After contacting for a certain period of time, methods such as separating the adsorbent, etc., make the wort or fermented liquid contact with the adsorbent. In addition, the process of treating with an adsorbent can be suitably implemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com