Read-in and read device of millimicro data using cantilever structure and its manufacturing method

A technology for data writing and reading equipment, applied in the use of micro-probe methods, data recording, instrument parts, etc., can solve problems such as affecting product yield, increasing cost probe wear, and reducing product yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0047] Multiple embodiments of the nanodata writing and reading device using the cantilever structure according to the present invention may exist, and the most preferred embodiment will now be described.

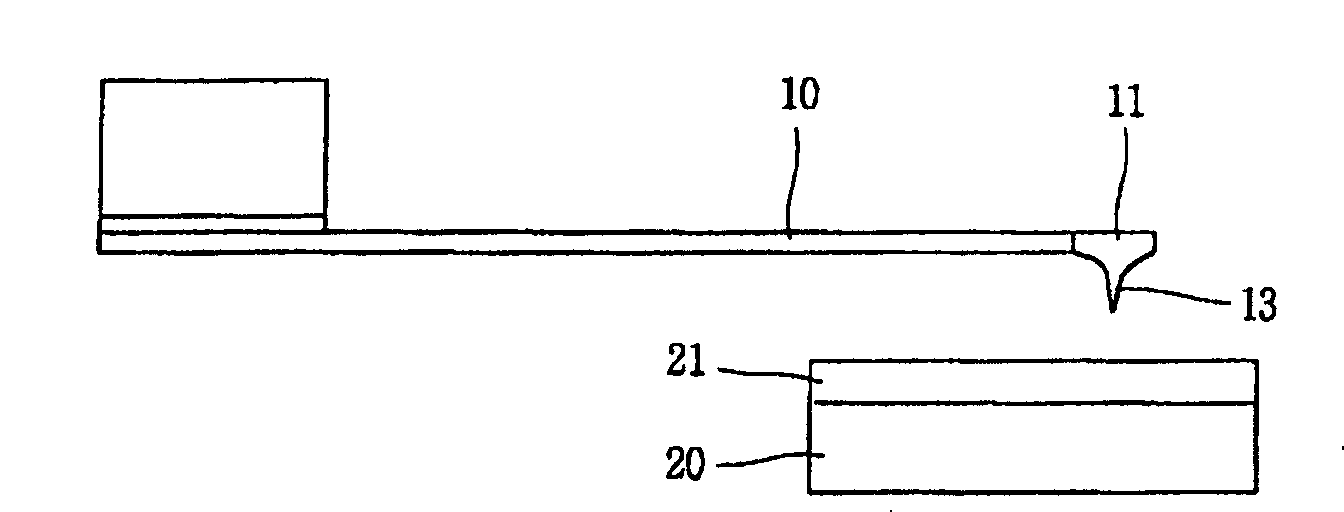

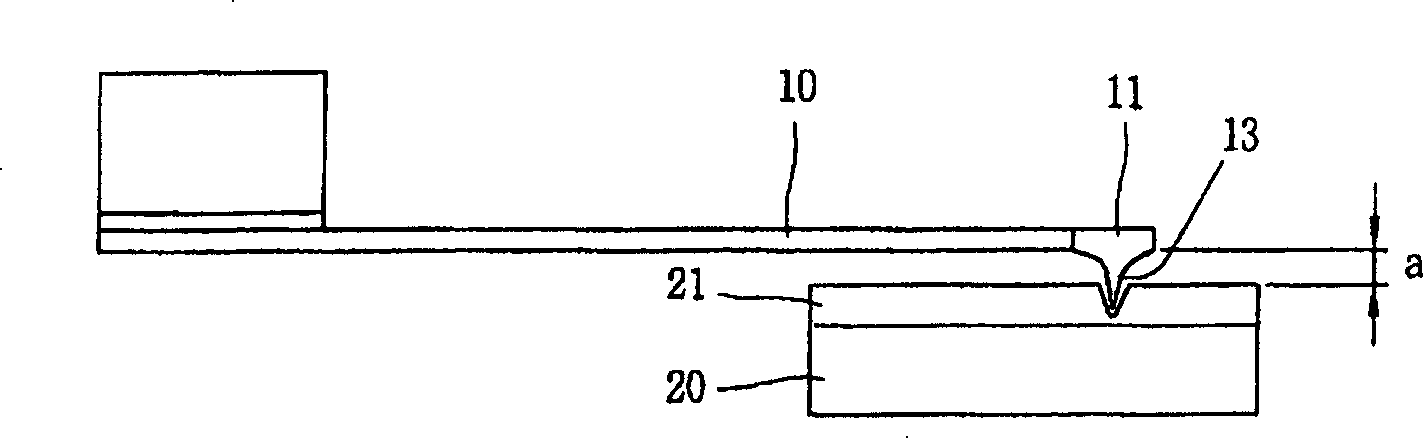

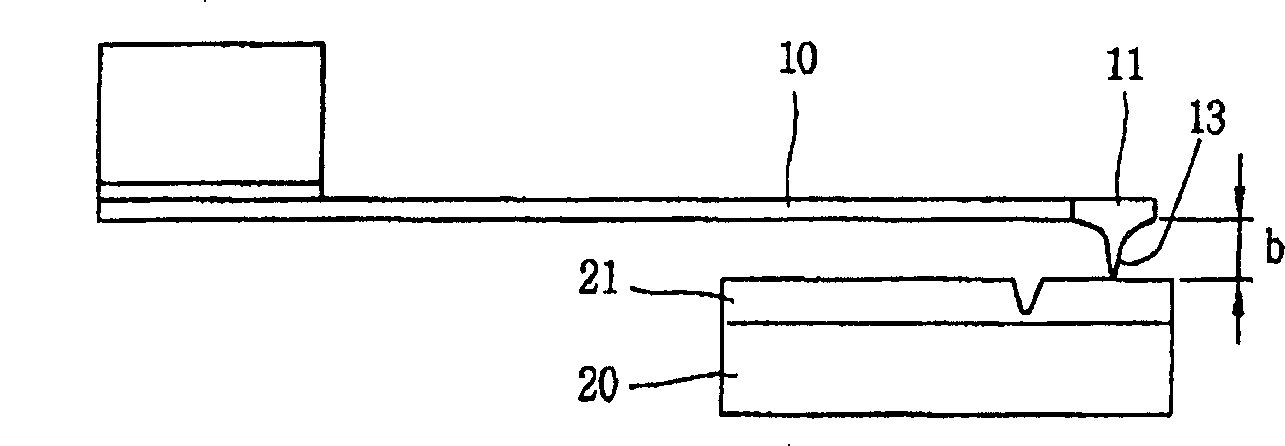

[0048] Figures 5A to 5C is a structural diagram illustrating the cantilever structure 300 according to the first embodiment of the present invention. Figure 5A is the exploded perspective view of the cantilever structure, Figure 5B is the assembled perspective view of the cantilever structure, and Figure 5C is a sectional view illustrating that the signal transmission circuit unit 400 for controlling and supporting the cantilever structure is bonded to the cantilever structure 300 .

[0049] As shown in the figure, a nanodata writing and reading device using a cantilever structure according to a first embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com