Precise fertilizer feeder

A fertilizer discharger and precision technology, applied in the field of agricultural appliances, can solve the problems of fluctuation of fertilizer discharge, precise control of affecting fertilizer discharge, fertilizer leakage, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

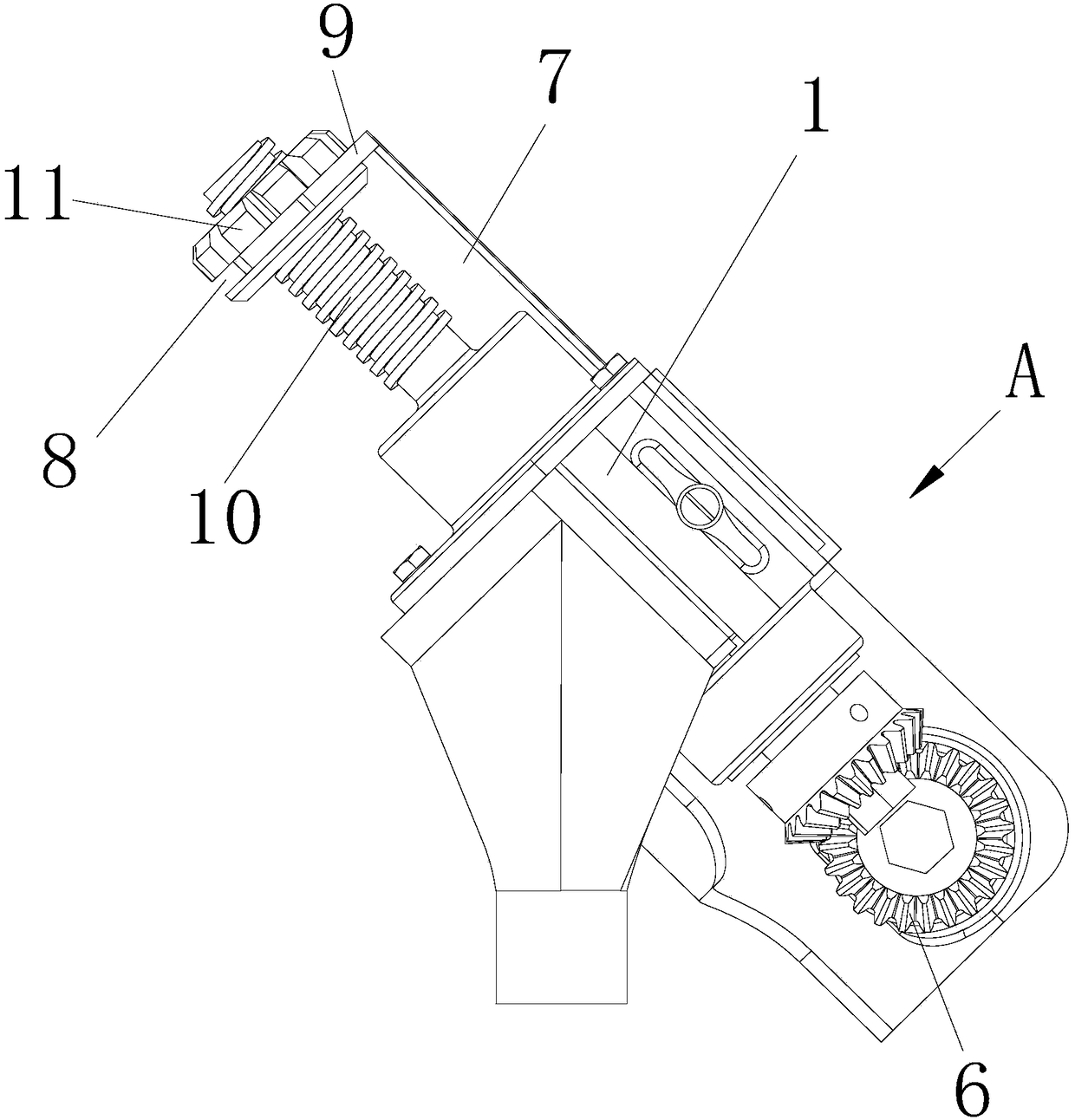

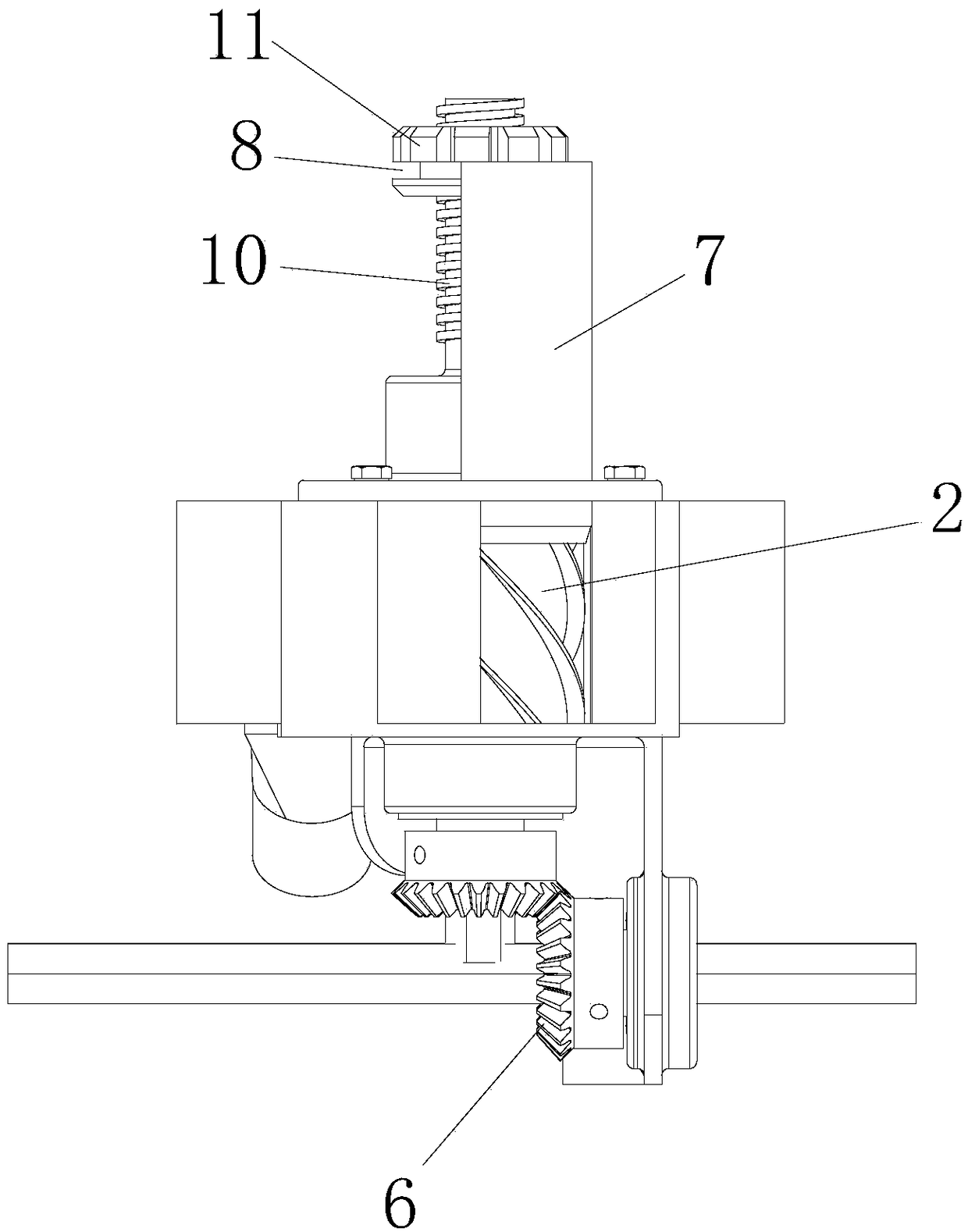

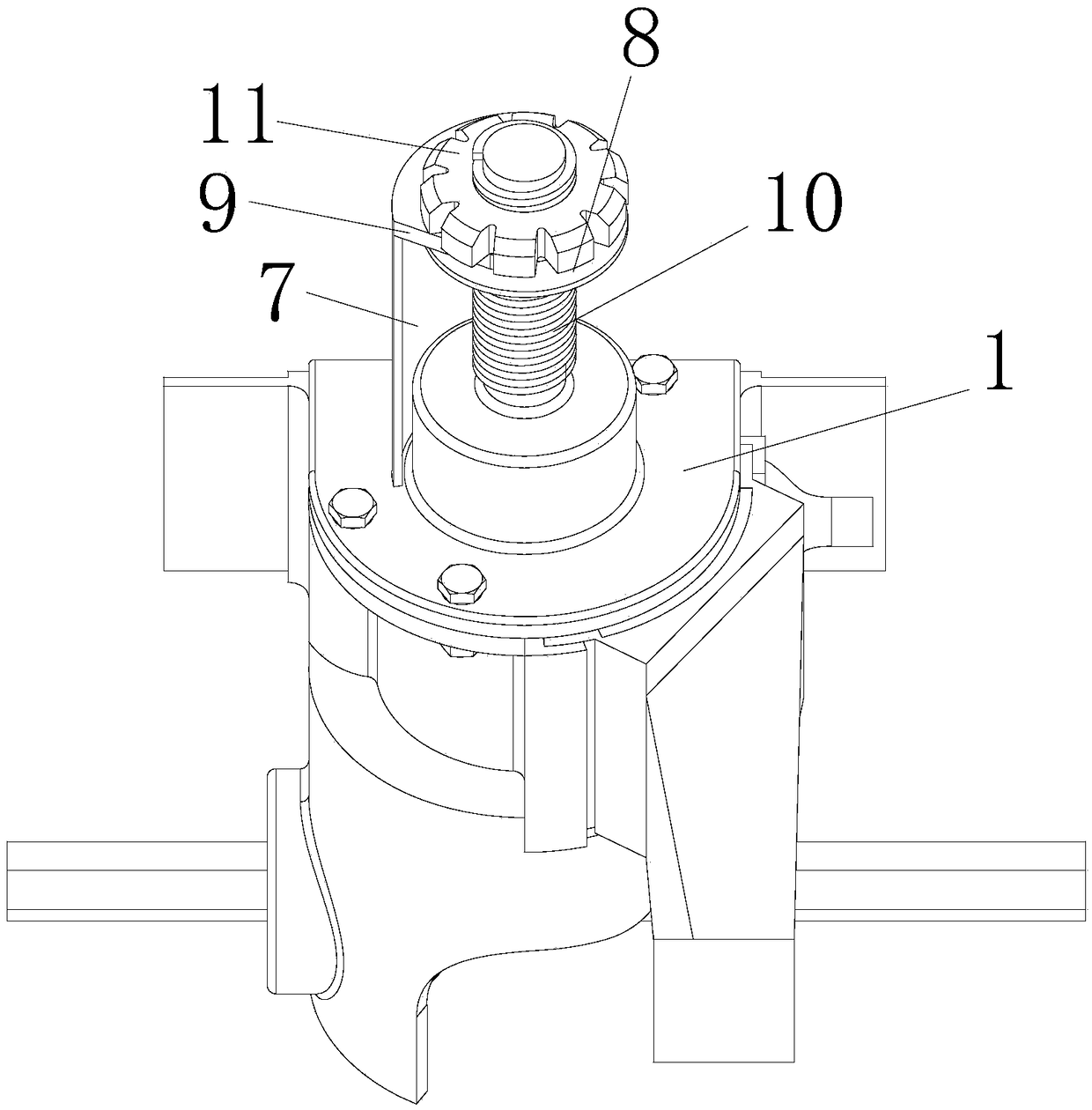

[0025] Such as Figure 1-3 As shown, a precision fertilizer discharger includes a housing 1 and a spiral sheave 2. The housing 1 has a conveying channel 3, and the helical sheave 2 is arranged in the conveying channel 3. The helical sheave 2 is used to transport fertilizer From the delivery channel inlet 4 to the delivery channel outlet 5, an opening adjustment mechanism for adjusting the opening of the delivery channel inlet 4 and / or the delivery channel outlet 5 is also provided.

[0026] The transfer runner inlet 4 is connected with the fertilizer box 16, wherein, as Figure 7 As shown, the angle α formed by the intersection of the axial direction of the precision fertilizer device and the horizontal plane is 110°-150°. Preferably, the angle α formed by the intersection of the axial direction of the precision fertilizer device and the horizontal plane can be 115°, 121°, 137° °, 145° or 148°. This setting can optimize the force of the fertilizer discharge process and preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com