Automatic-adjusting button sewing machine

An automatic adjustment and buttoning machine technology, applied in the field of buttoning machines, can solve the problems of affecting work efficiency, unable to fine-tune, and produce fatigue, and achieve the effects of reducing labor intensity, convenient adjustment, and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

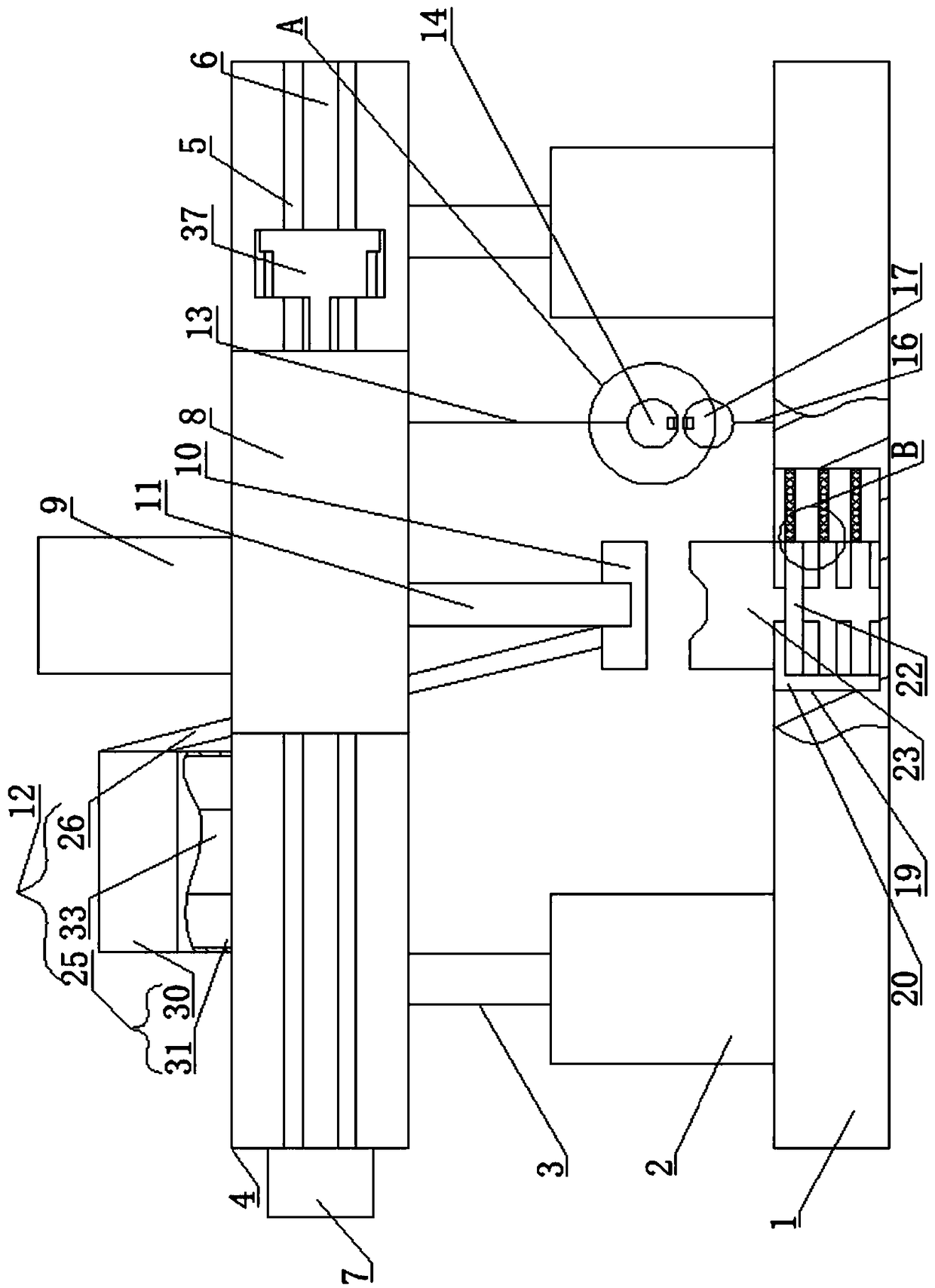

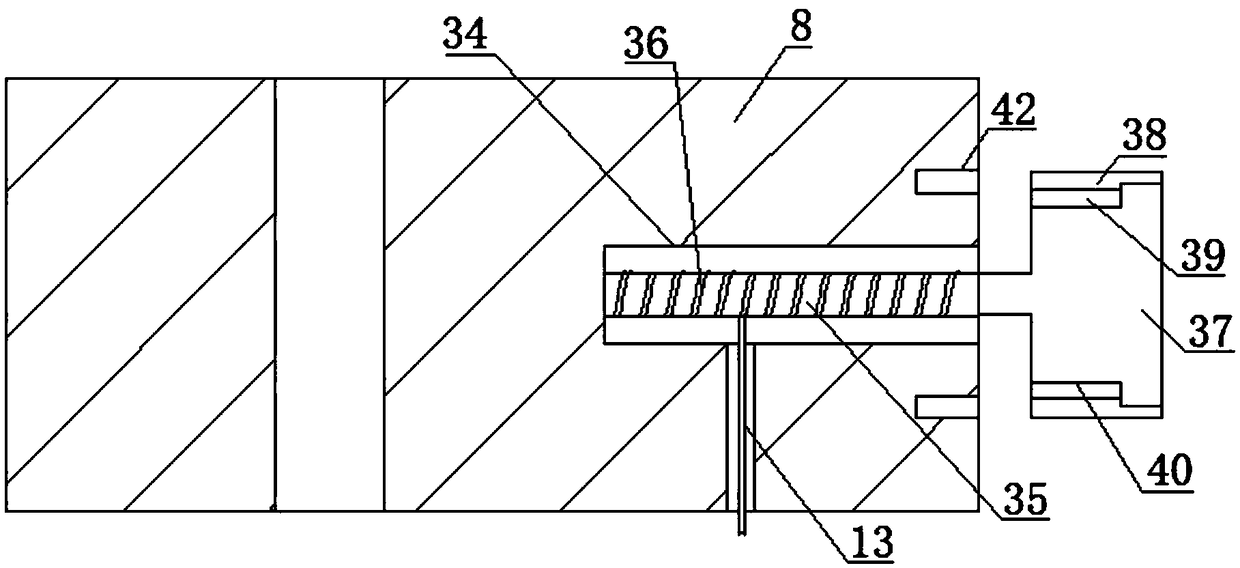

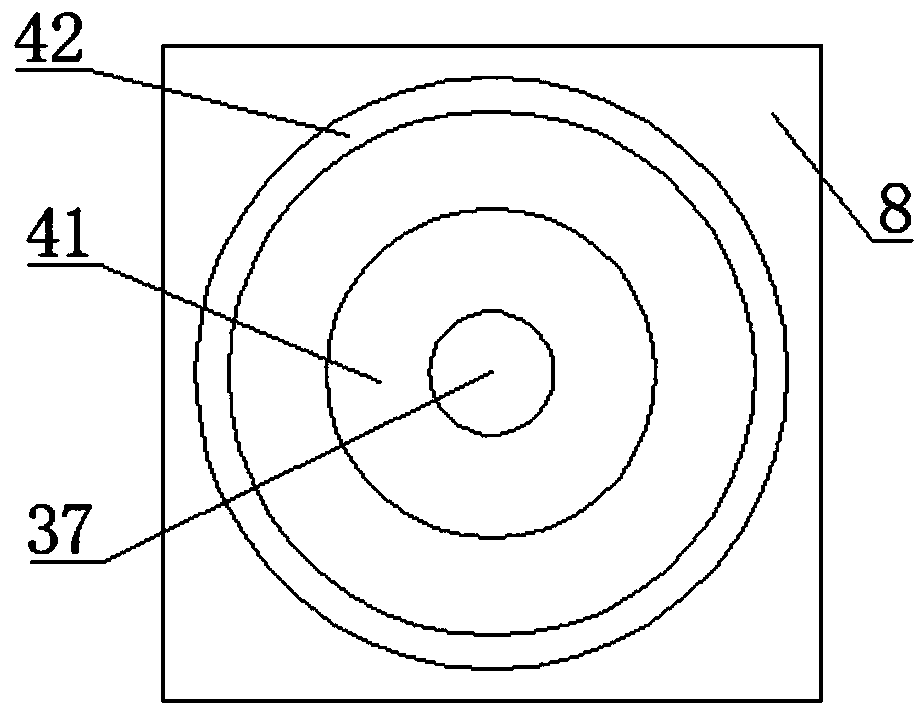

[0020] Example. The automatic adjustment type button sewing machine is composed of Figures 1 to 6 As shown, including a base 1, two first cylinders 2 are installed on the upper surface of the base 1; the first push rods 3 are connected to the two first cylinders 2, and the ends of the two first push rods 3 are installed There is a top plate 4; the middle part of the top plate 4 is provided with a first groove 5, and a ball screw 6 is installed in the first groove 5; one end of the ball screw 6 is connected with a first motor 7, and a moving motor 7 is installed on the ball screw 6. Seat 8; the first hydraulic cylinder 9 is installed on the mobile seat 8, and the upper punch 10 is connected to the first hydraulic cylinder 9; the first hydraulic rod 11 is connected between the upper punch 10 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com