A Method for Accurately Changing Templates of a Four-station Horizontal Core Making Machine

A core-making machine and four-station technology, which is applied to parts of molding machines, molding machines, and manufacturing tools, etc., can solve the problems of high economic cost, cumbersome steps, inability to use, etc., and achieve accurate position, correct orientation, The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

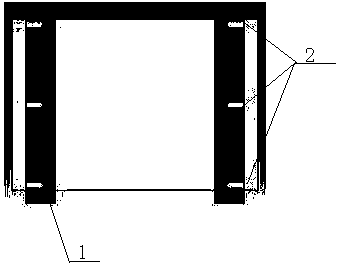

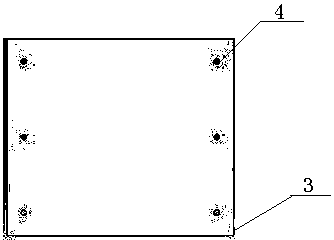

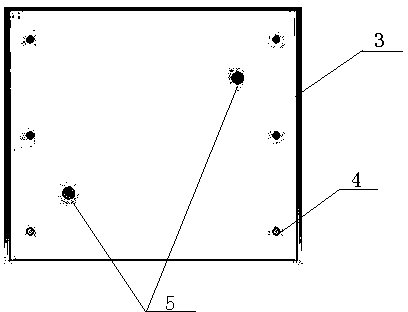

[0035] Such as Figure 1-2 As shown, the existing four-station horizontal core making machines have different mold pin hole positions and different sand box sizes. When the mold is replaced each time, there are six U-shaped grooves 2 on the mold support leg 1, which can be used from different molds. The direction is fastened on the connecting plate 3 of the four-station horizontal core making machine, and there are six fastening holes 4 on the connecting plate, and the diameter of the through hole is 18mm. Put the mold support legs on the connecting plate, and then pass The bolts fix the U-shaped groove on the mold supporting leg and the fastening hole on the connecting plate to fix the mold supporting leg and the connecting plate. Engineers guide the replacement.

[0036] In order to more accurately and quickly replace the mold of the iron mold sand-coated line, the present invention provides a method for accurately replacing the template of a four-station horizontal core ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com