A kind of aluminum alloy sheet welding method

A thin plate welding and aluminum alloy technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of easy deformation of aluminum alloy thin plates and low joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

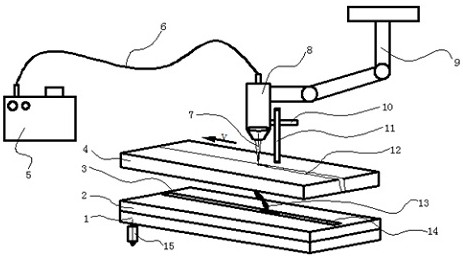

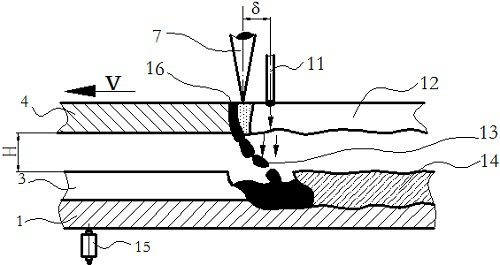

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] As shown in Figures 1-3, an embodiment of the present invention provides a method for welding an aluminum alloy sheet including the following steps:

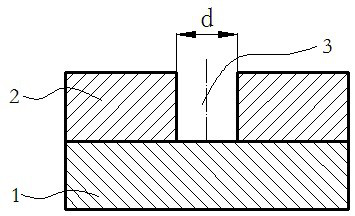

[0032] Step 1: Provide the first workpiece 1 and the second workpiece 2 that need to be welded together, stamp and form a transparent slit 3 along the welding track on the second workpiece 2, and remove the upper and lower surfaces of the first workpiece 1 and the second workpiece 2 and slit 3 impurities.

[0033] Optionally, both the first workpiece 1 and the second workpiece 2 are aluminum alloy, and the thickness of the first workpiece 1 and the second workpiece 2 are both 0.8-1.5 mm.

[0034] Optionally, the width d of the slit 3 is 0.5-1.2 mm.

[0035] Step 2: Accurately overlap and clamp the first workpiece 1 and the second workpiece 2 .

[0036] Step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com