A Welded Bracket for Pedal Front Column with Reliable Positioning

A welding bracket and positioning template technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding efficiency and repeated positioning, and achieve high welding accuracy, improve processing accuracy, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

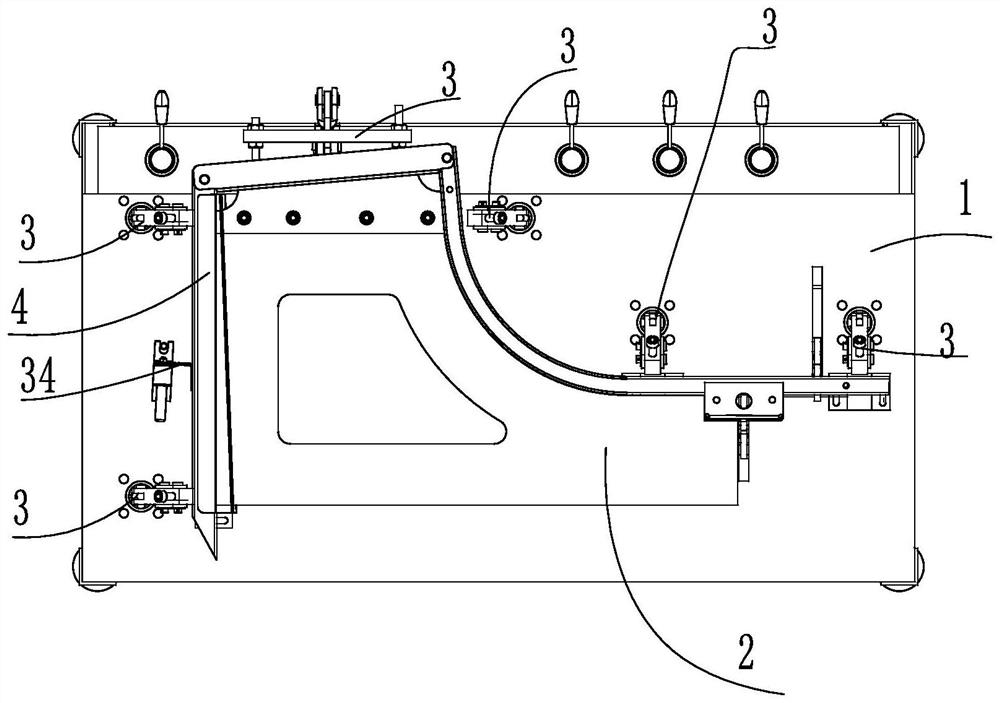

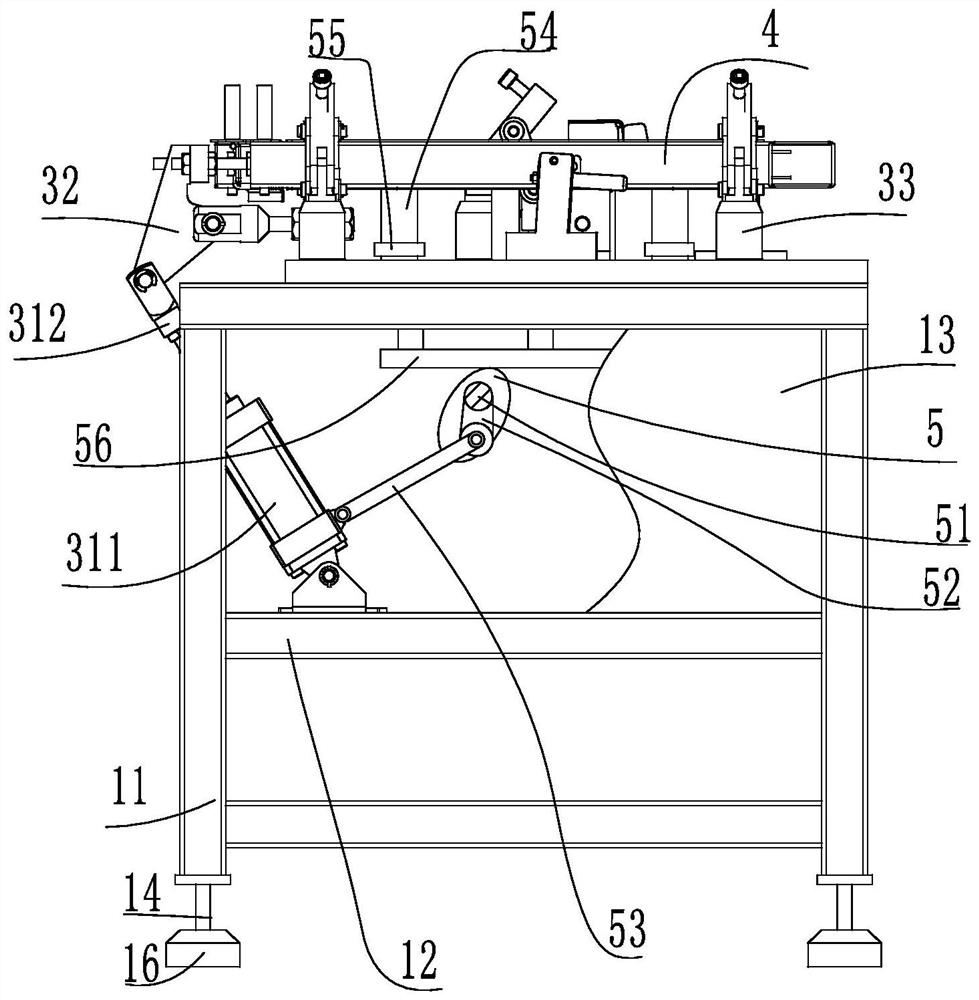

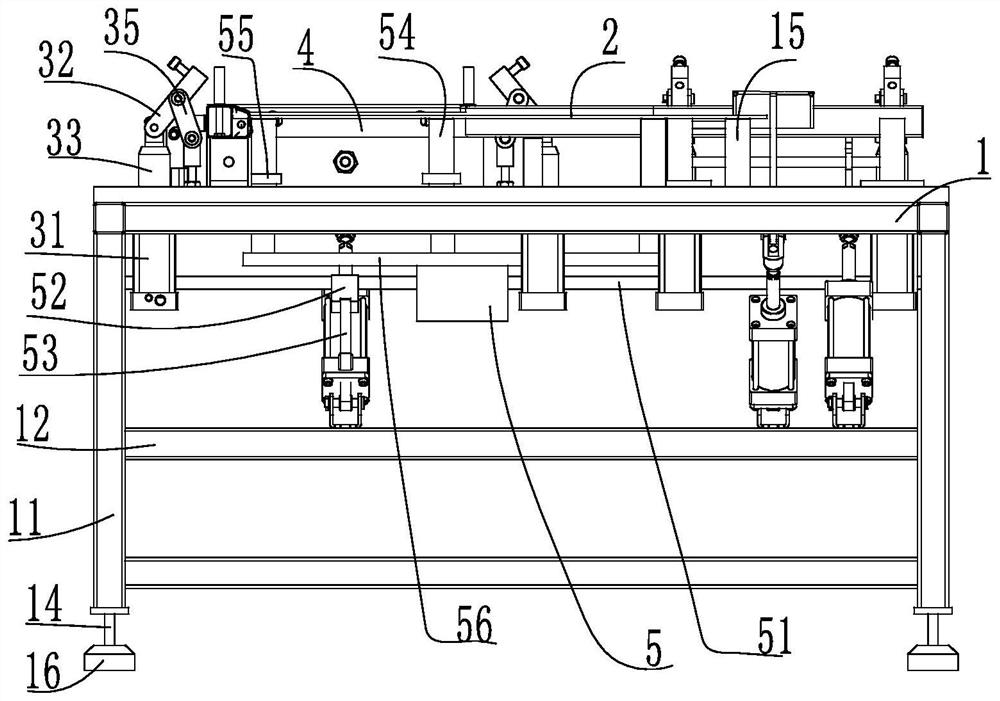

[0031] Figure 1 to Figure 6 Among them, a pedal front column welding bracket with reliable positioning includes a working platform 1, and the working platform 1 includes platform vertical rods 11 located at four corners. The platform vertical rods 11 are connected and fixed by horizontally arranged platform beams 12. There is a protective plate 13 . The lower side of the working platform 1 is provided with a friction stand 14 with adjustable height. The friction stand 14 is connected to the lower end of the platform vertical rod 11 through a thread. The height of the friction stand 14 can be adjusted by twisting the thread. It is a rubber pad 16 with bumps. The working platform 1 is provided with a column die 4, a fixing tool 3 and a positioning template 2. The column die 4 includes a cross bar 41, a longitudinal bar 42 and a bending bar 43 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com