Easy-to-adjust transmission system

A transmission system, driving gear technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of bulky, high cost, and complicated manufacturing of the transmission box, and achieve high transmission efficiency, simple structure, and difficult silky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

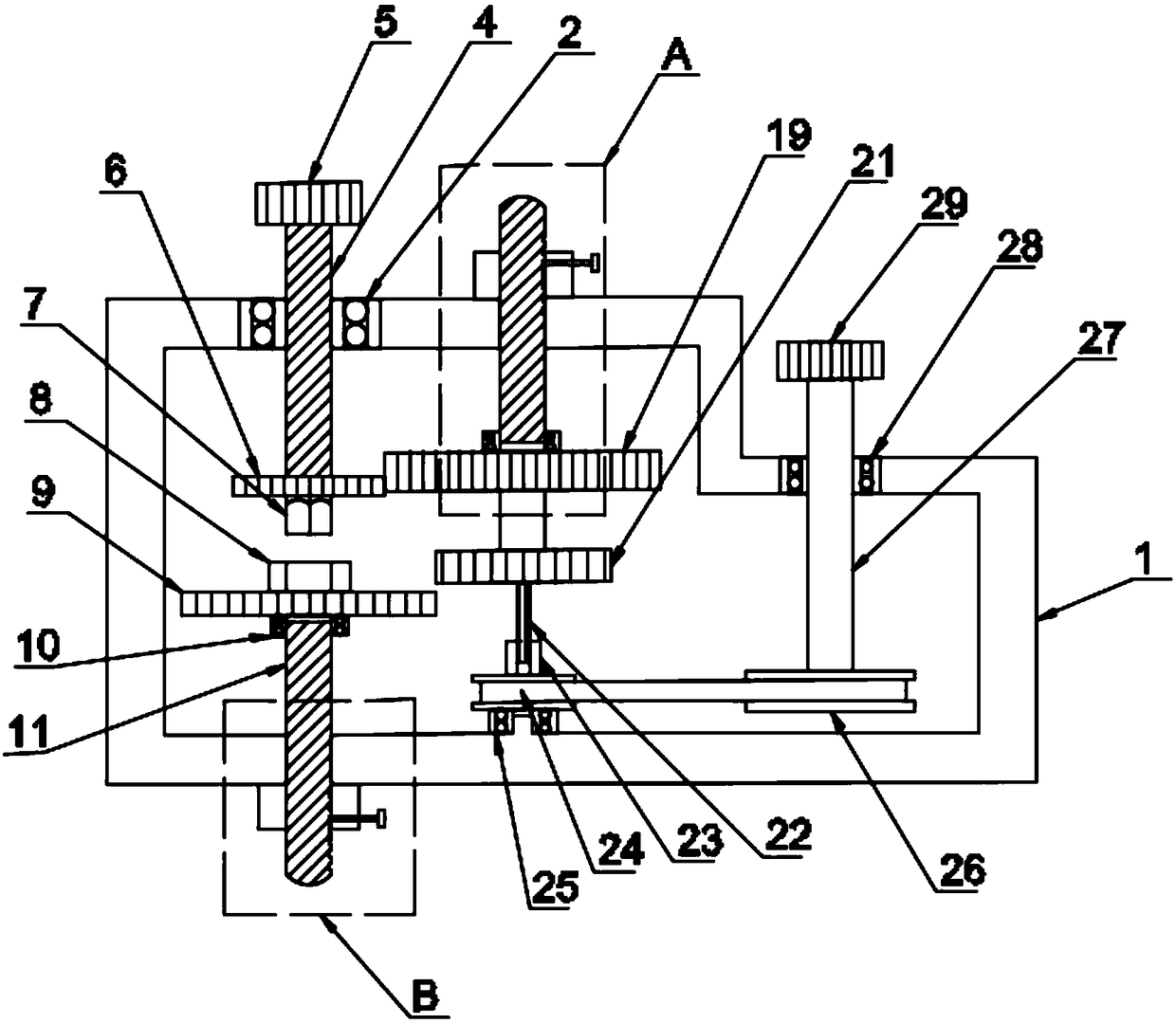

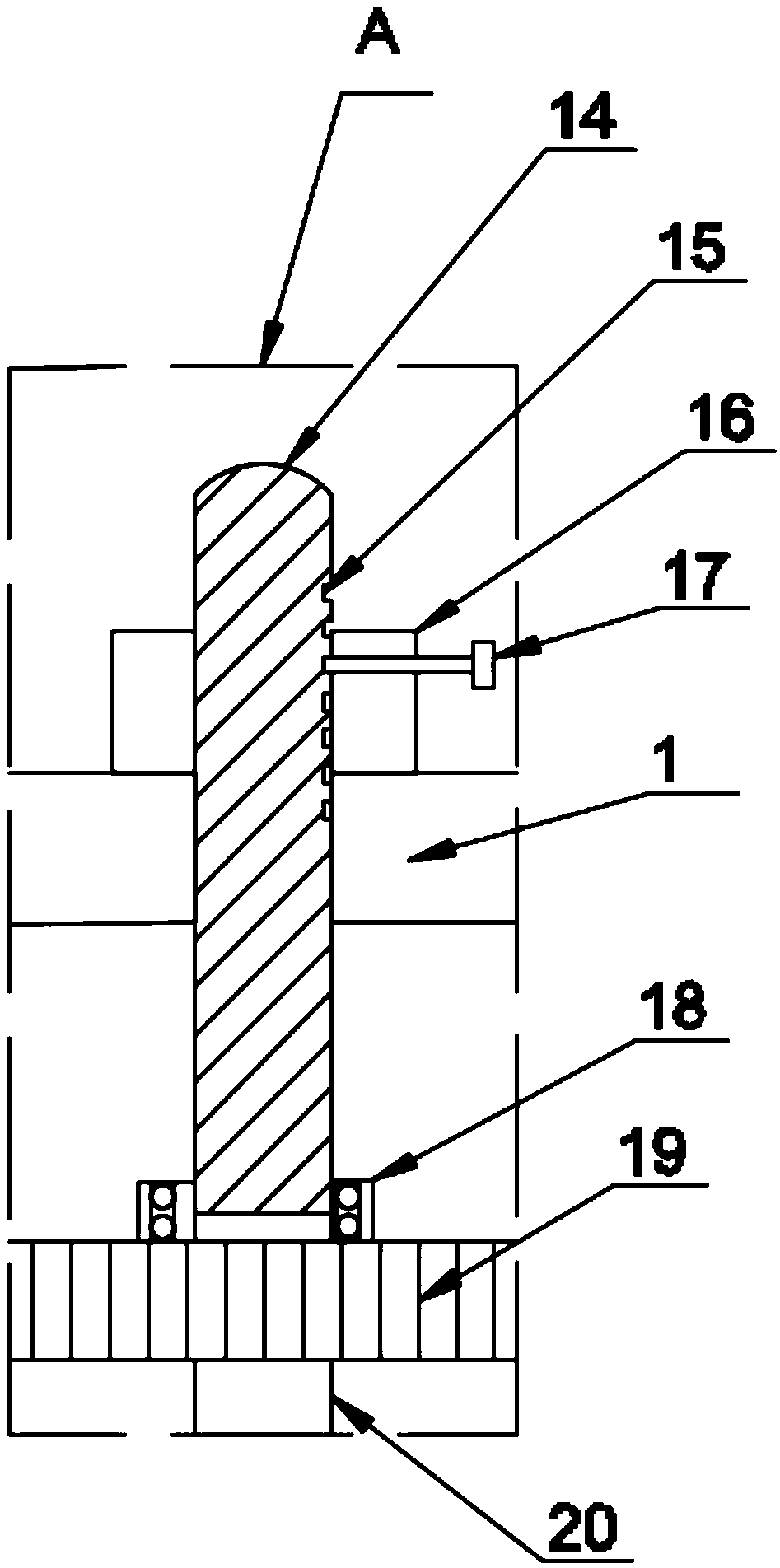

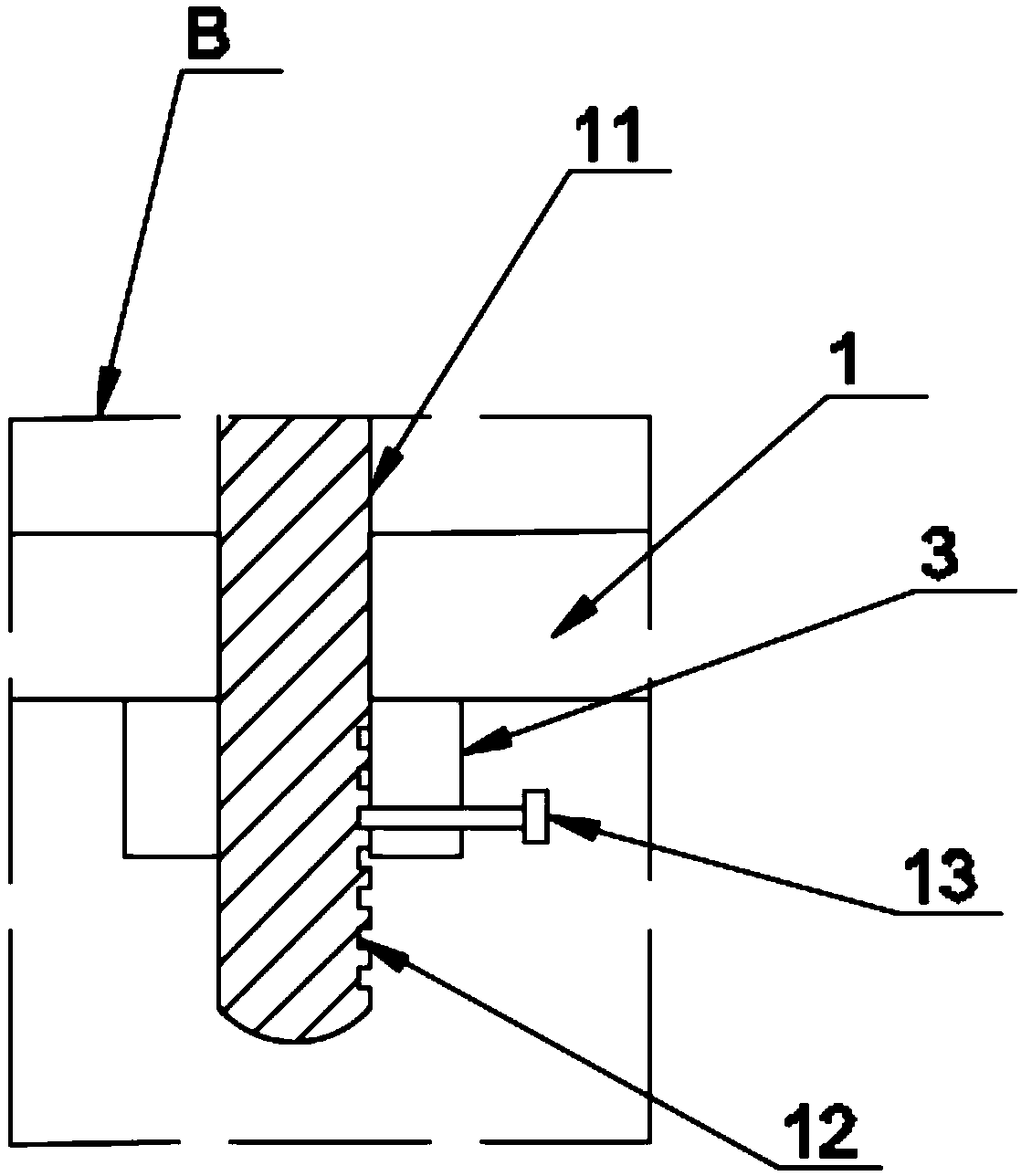

[0024] Such as Figure 1-4 The illustrated transmission system for easy adjustment includes a box body 1, a first bearing 2 is embedded on one side wall of the box body 1, and a first stop ring 3 is arranged on the other side wall. A bearing 2 is penetrated with a first rotating shaft 4, one end of the first rotating shaft 4 is provided with a first connecting gear 5 and the other end is provided with a first driving gear 6, and one side of the first driving gear 6 is provided with The first connecting rod 7, one end of the first connecting rod 7 is provided with a first connecting pipe 8, the end of the first connecting pipe 8 is provided with a second driving gear 9, and one side of the second driving gear 9 is provided with The second bearing 10, the inner ring of the second bearing 10 is fixedly connected with the first fixed shaft 11, the outer wall of the end of the first fixed shaft 11 is provided with a plurality of first limiting holes 12, and the limiting ring is A ...

Embodiment 2

[0028] Such as Figure 1-4 A transmission system that is easy to adjust is shown, the first synchronous wheel 24 is provided with a second synchronous wheel 26 on one side, and the side wall of the second synchronous wheel 26 is fixedly provided with a third rotating shaft 27, and the third synchronous wheel 26 is fixed on the side wall. The outer wall of the rotating shaft 27 is covered with a fifth bearing 28, the end of the third rotating shaft 27 is provided with a second connecting gear 29, the first driving gear 6 is meshed with the third driving gear 19, and the first connecting gear 6 is engaged with the third driving gear 19. The rod 7 and the second connecting rod 22 are all arranged in a regular hexagonal column shape, the outer wall of the first connecting rod 7 coincides with the inner wall of the first connecting pipe 8, and the outer wall of the second connecting rod 22 coincides with the inner wall of the second connecting pipe 23 .

[0029] The second drive g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com