Mounting structure for lift type security monitoring equipment carrier cart

A technology of installation structure and security monitoring, applied in the direction of mechanical equipment, supporting machine, machine/stand, etc., can solve the problems of high airflow speed, shaking of the installation structure, inability to automatically descend, etc., to avoid unnecessary work, avoid angle offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

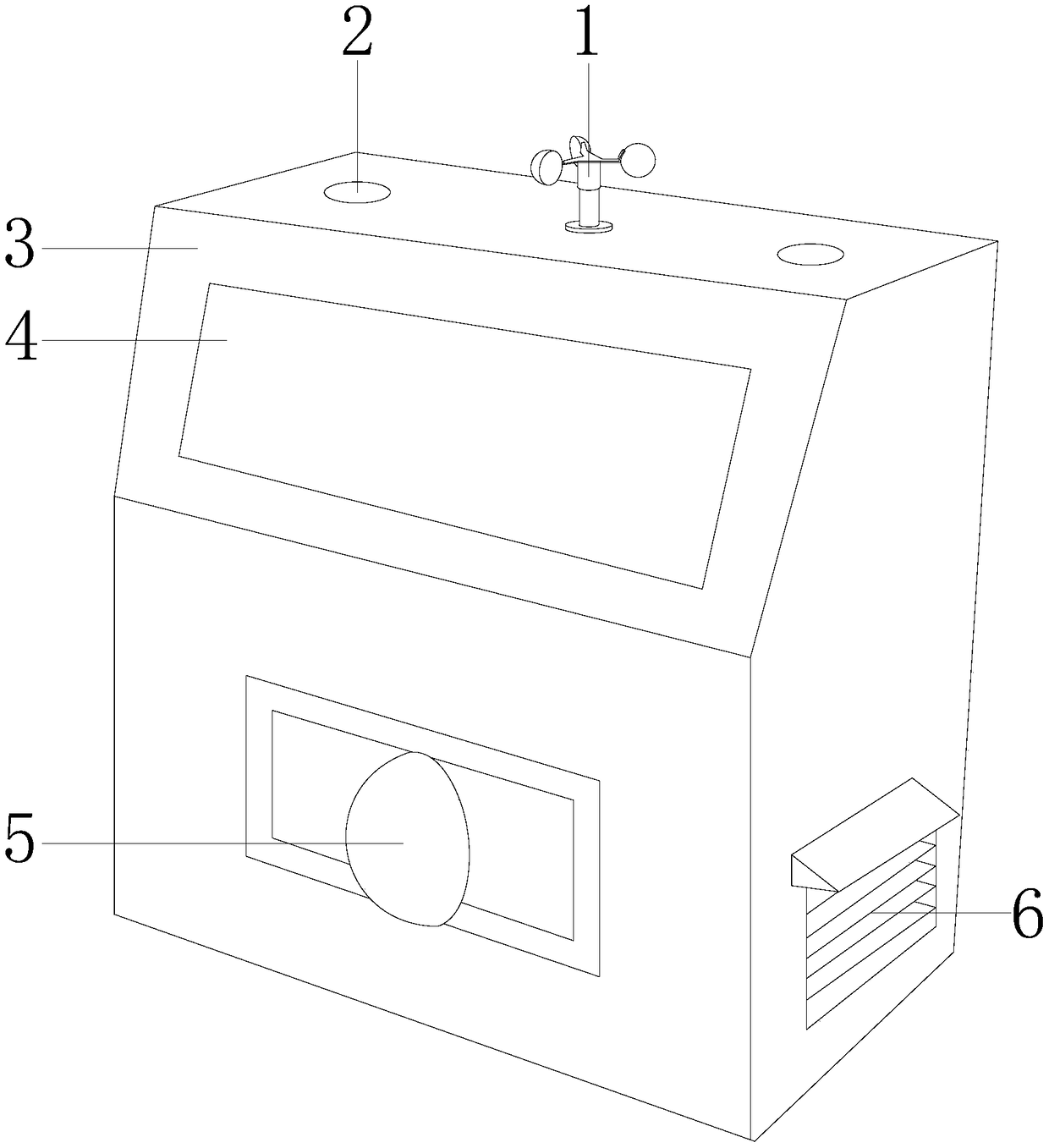

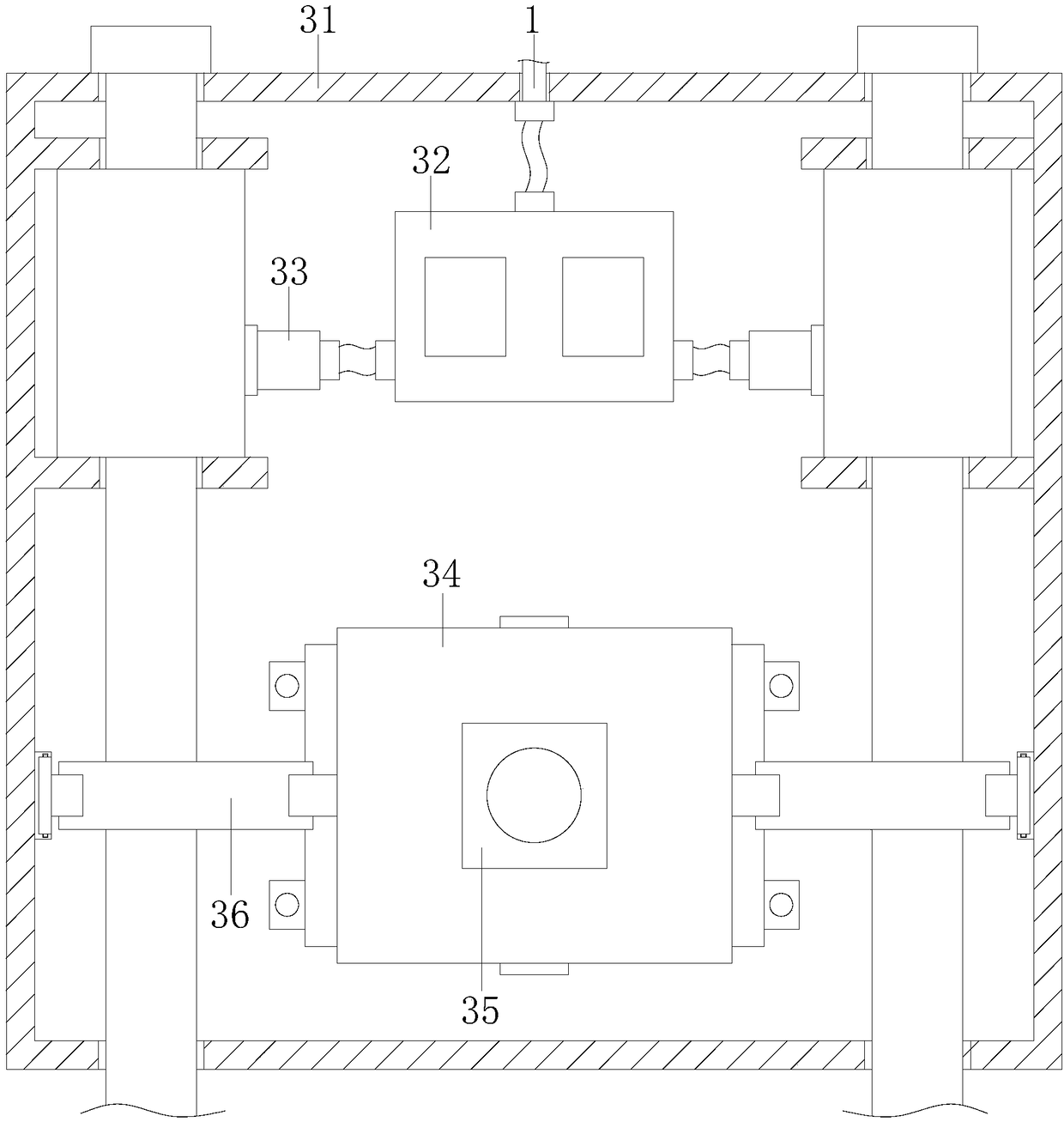

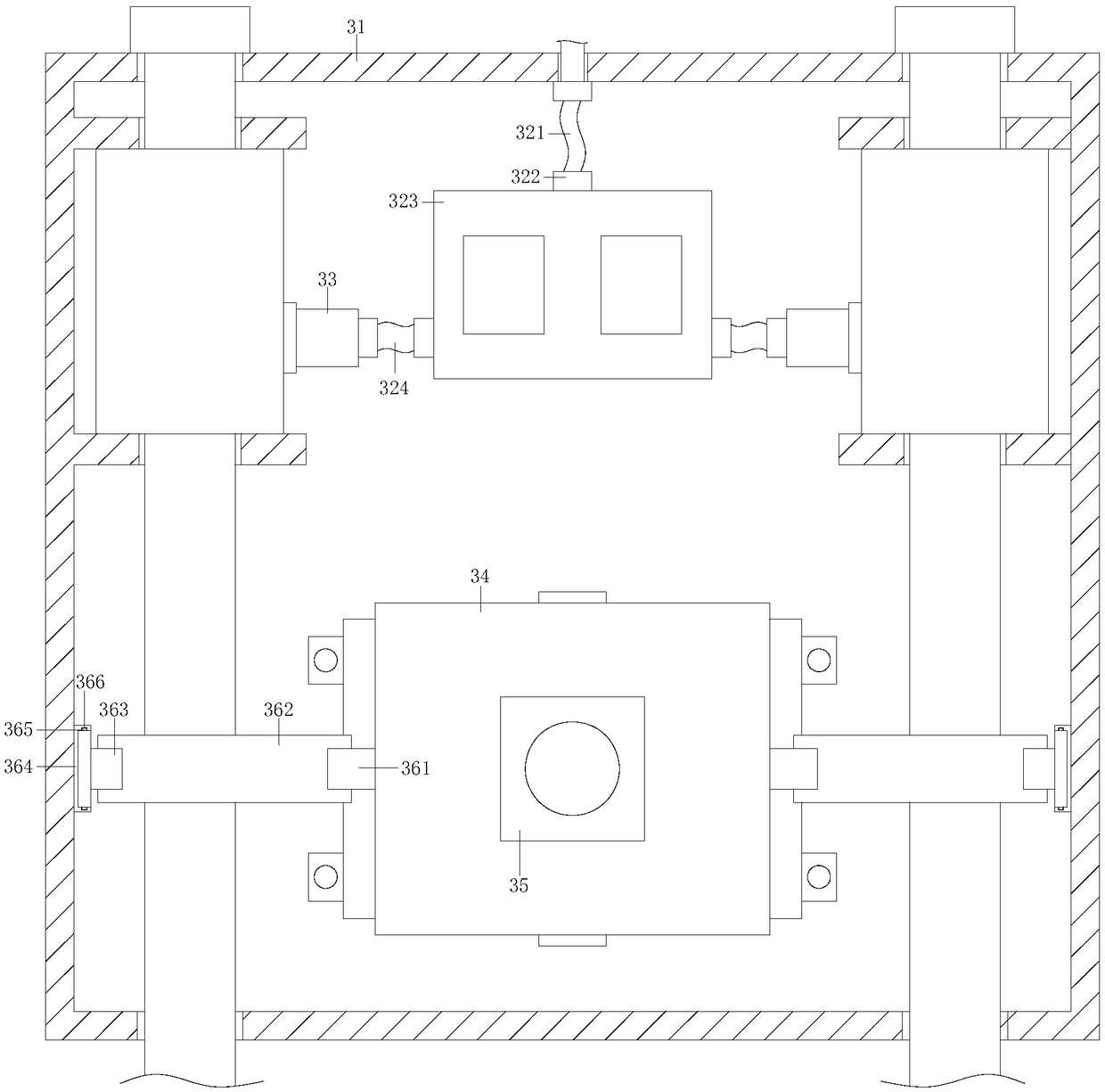

[0028] see Figure 1-Figure 6 , the present invention provides an installation structure for carrying a trolley with lifting security monitoring equipment. At the top of the structure 3, the lifting hole 2 is embedded in the installation structure 3, the front surface of the top of the installation structure 3 is provided with a window 4, the bottom of the installation structure 3 is embedded with a camera 5 and is electrically connected by a wire, the heat dissipation hole 6 is embedded on the outer surface of the installation structure 3, and the installation structure 3 includes a housing 31, a control mechanism 32, a lifting mechanism 33, a stabilization mechanism 34, a camera mount 35, and a fixing mechanism 36.

[0029] The wind speed sensor 1 is vertically installed on the top of the casing 31, and the top inside of the casing 31 is provided with a control mechanism 32, the control mechanism 32 is electrically connected with the wind speed sensor 1 through a wire, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com