Flame stabilization device, combustion device and test method

A flame stabilization and combustion device technology, which is applied in the field of combustion devices and flame stabilization devices, can solve the problems of reduced flame stability performance, increased resistance, and inability to adjust, and achieves the effects of low cost, good performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

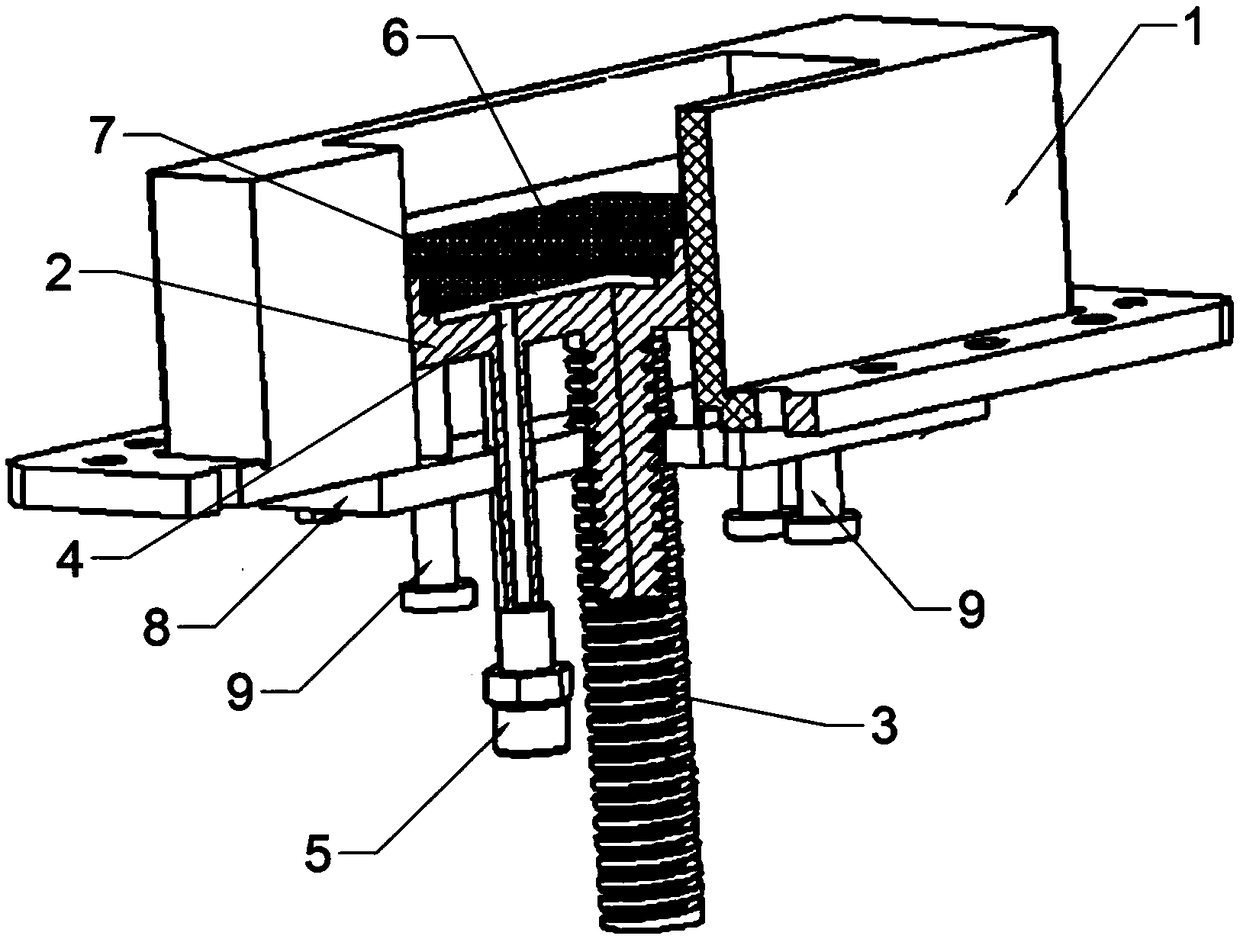

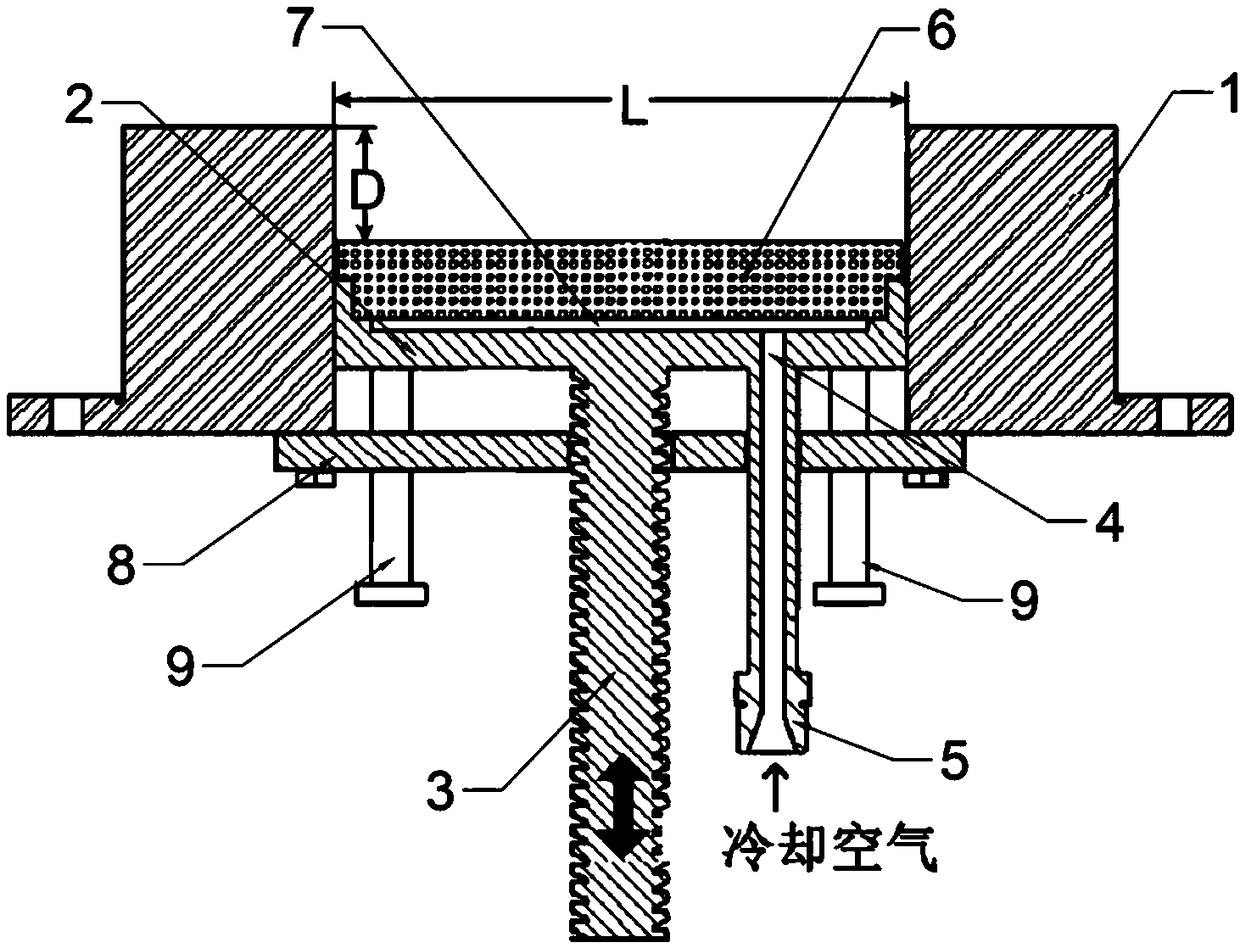

[0035] Such as figure 1 As shown, the flame stabilizing device of the present embodiment includes a base, a sliding plate and a translation transmission rod; the base has a recessed cavity; the sliding plate is arranged in the cavity, and can move along the axis of the cavity in the cavity. to move; the translation transmission rod is fixedly installed on the bottom surface of the slide plate. In this embodiment, the translation transmission rod is a worm. Driven by a driver such as a driving motor, the sliding plate can be pushed to slide in translation along the axial direction of the cavity in the cavity. It should be noted, figure 1 It is a partial sectional view of the flame stabilizer with one corner cut away. Such as figure 2 As shown in , L represents the length of the cavity, and D represents the depth of the cavity. By sliding the sliding plate up and down in the cavity, the depth of the cavity can be continuously adjusted, so that the length-depth ratio of the...

Embodiment 2

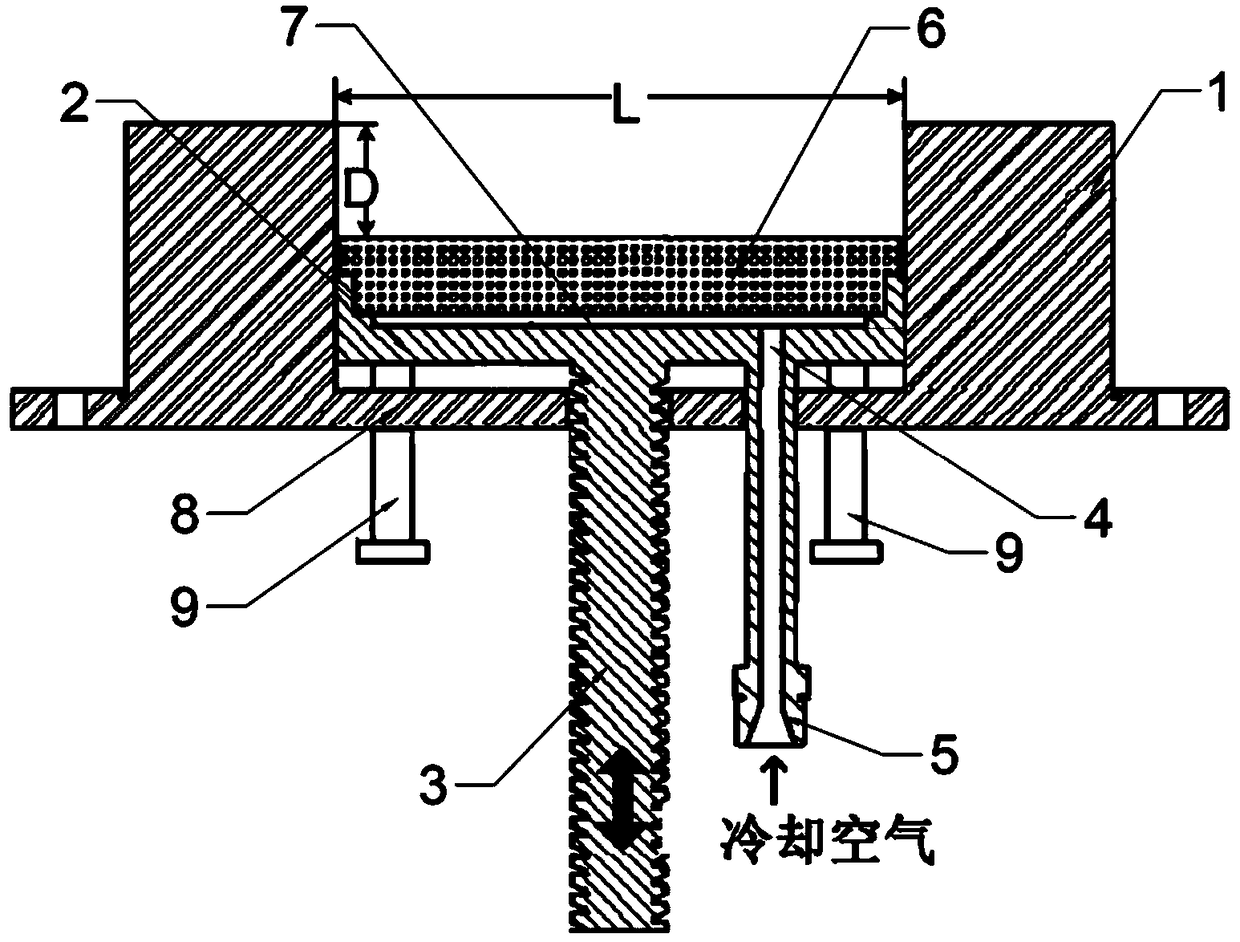

[0044] The flame stabilizing device of this embodiment is basically the same as that of Embodiment 1, the difference is that no bottom plate and positioning rod are provided, but a limiting block, a first positioning body, a second positioning body and a limiting body that cooperate with the first positioning body are added. Technical features such as bit bars.

[0045] Specifically, such as Figure 4 and Figure 5 As shown, the flame stabilizing device of the present embodiment includes a base, a sliding plate and a translation transmission rod; the base has a recessed cavity; the sliding plate is arranged in the cavity, and can move along the axis of the cavity in the cavity. to move; the translation transmission rod is fixedly installed on the bottom surface of the slide plate. In this embodiment, the translation transmission rod is a worm. Driven by a driver such as a driving motor, the sliding plate can be pushed to slide in translation along the axial direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com