Special equipment driving system

A drive system and special equipment technology, applied in motor vehicles, control devices, transportation and packaging, etc., can solve problems such as poor drive performance, and achieve the effects of high integration, strong bearing capacity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

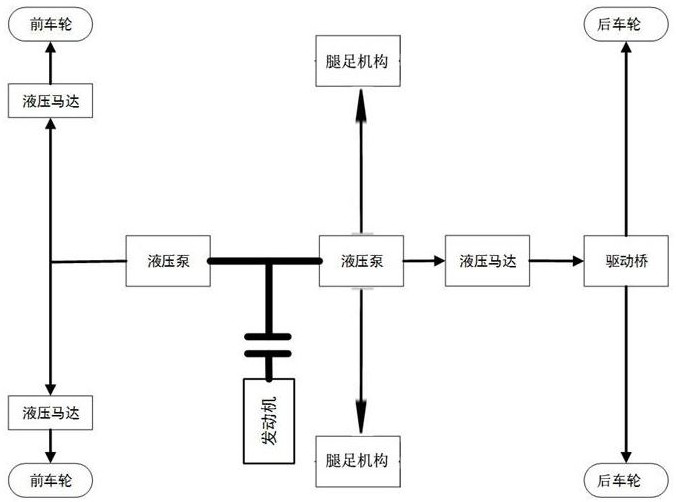

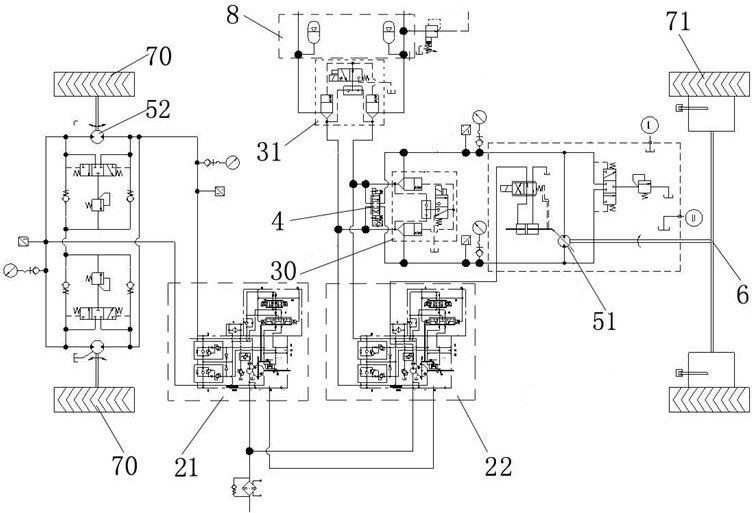

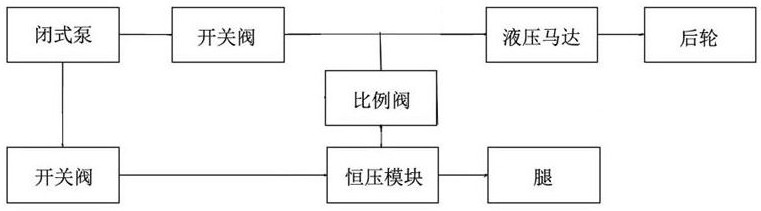

[0030] The special equipment driving system of the present invention is mainly applied to wheel-leg composite equipment, that is, engineering equipment including both driving wheels and leg-foot mechanisms.

[0031] The engineering equipment mainly used in the special equipment driving system of this embodiment includes a car body, and the front and rear ends of the car body respectively have a pair of front wheels and a pair of rear wheels. There are three leg and foot mechanisms arranged at the upper interval, that is, a wheel-leg composite equipment with four wheels and six legs. When this kind of composite equipment is in use, the leg-foot mechanism can be folded and retracted so that the wheels touch the ground. It can be used in a manner similar to a traditional vehicle. The leg-foot mechanism can be stretched out to touch the ground and output drive together with the wheels. This is the wheel-leg composite drive mode. Of course, under some usage requirements, the leg-fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com