Evaporator heat exchange device and integral air energy water heater

A technology of heat exchange device and evaporator, which is applied in the direction of evaporator/condenser, fluid heater, lighting and heating equipment, etc. It can solve the problems of poor heat transfer performance on the evaporation side and low heating capacity of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

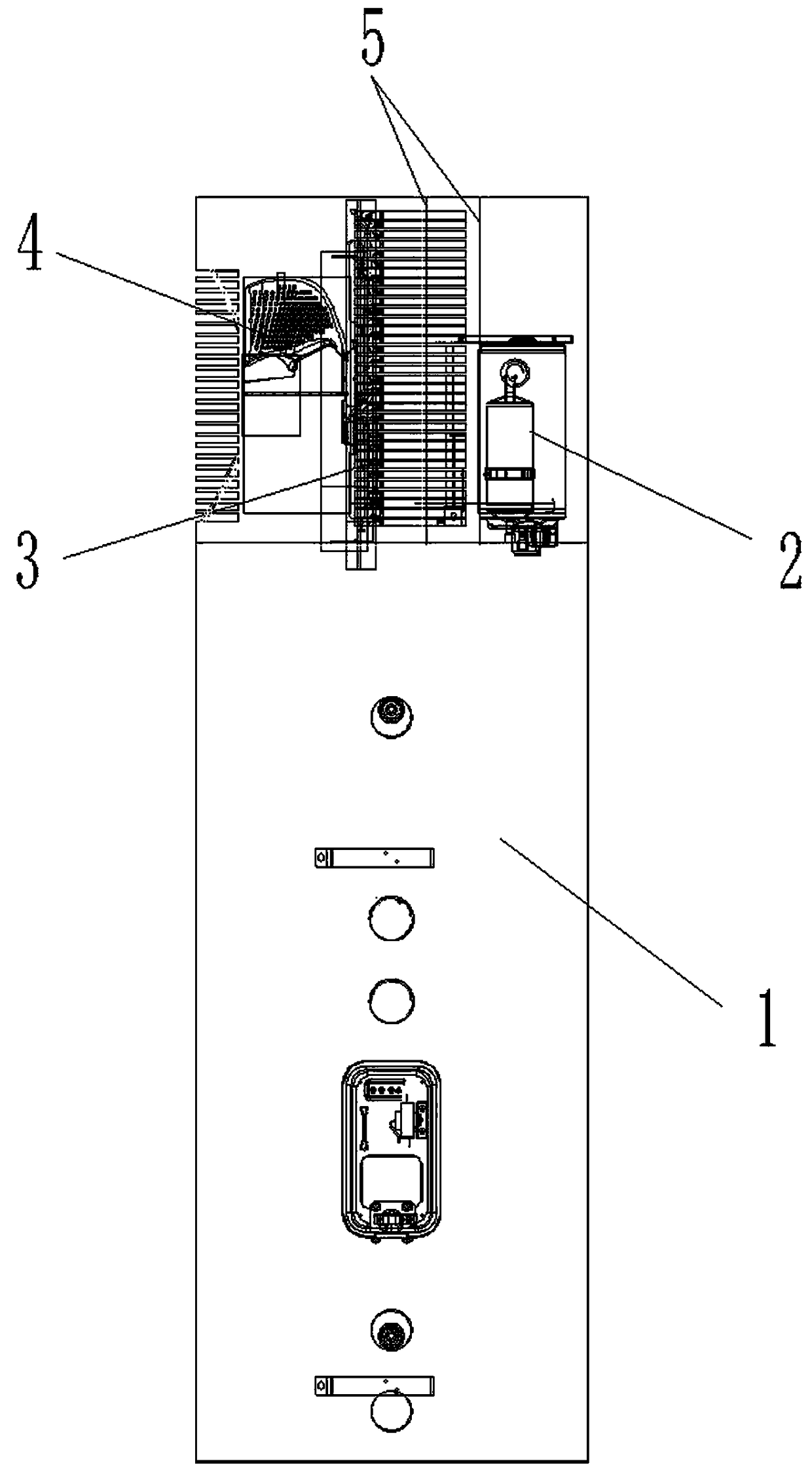

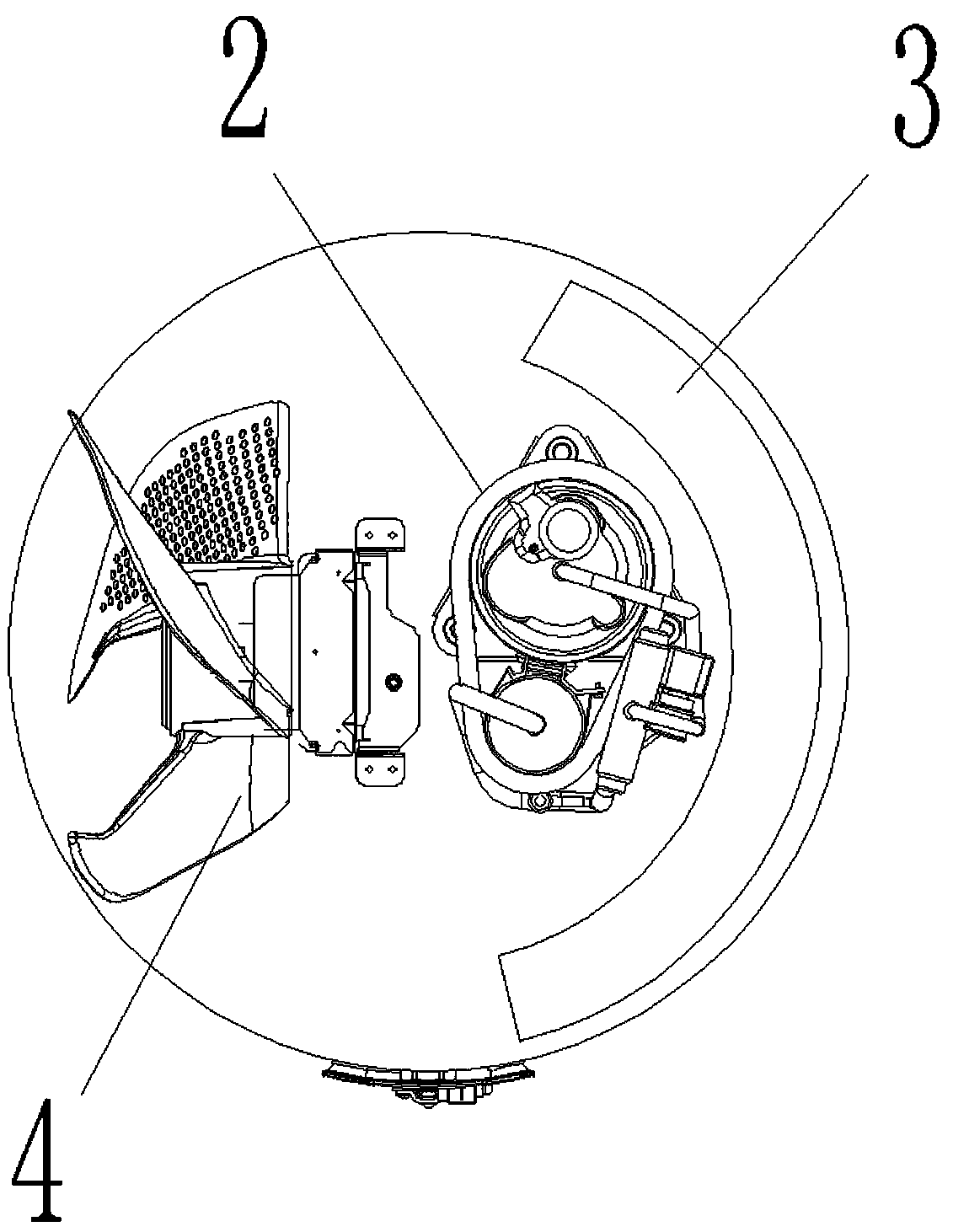

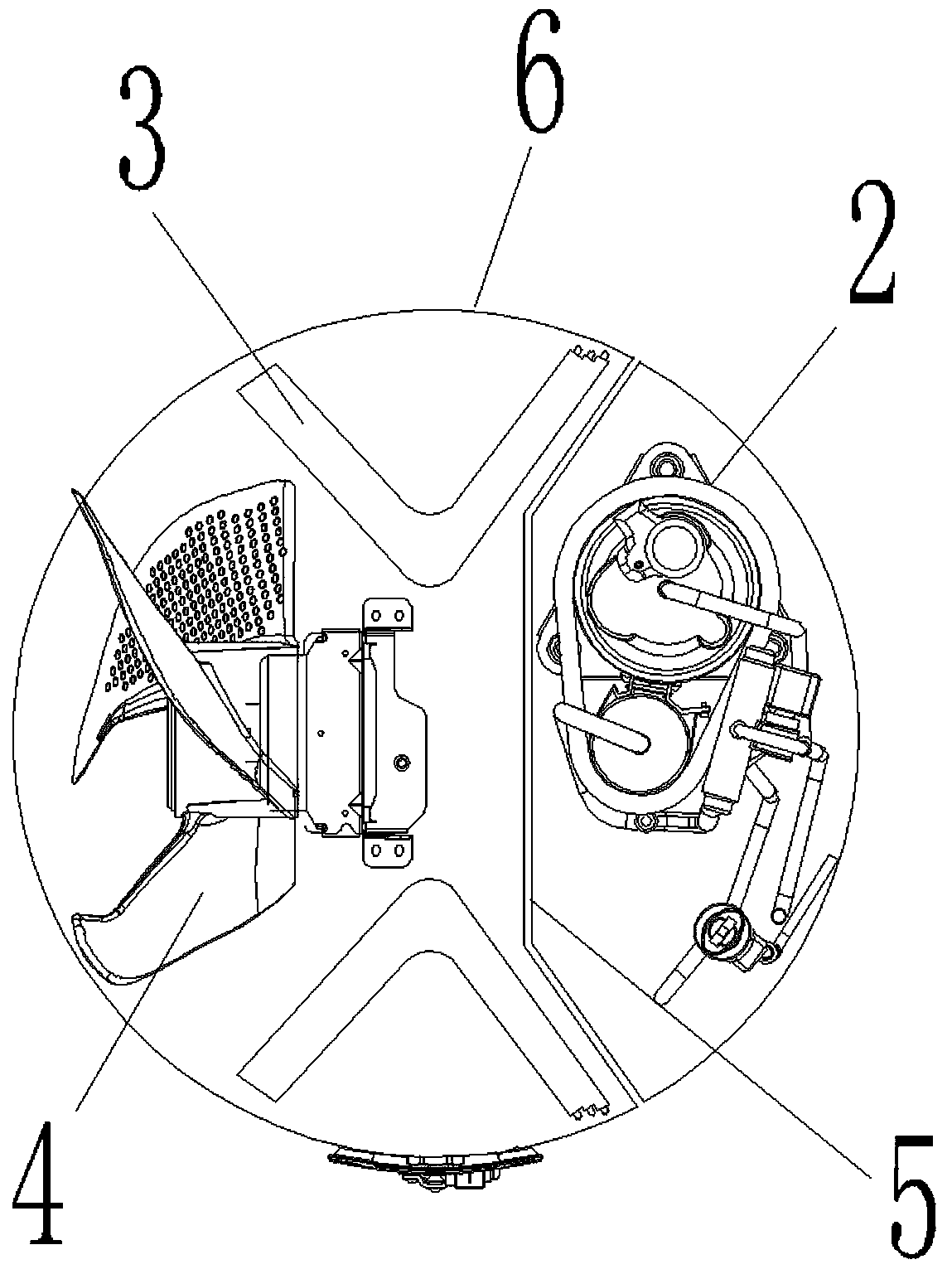

[0019] like figure 1 , image 3 , Figure 4 , Figure 5 Shown is the integrated air energy water heater proposed by the present invention and three kinds of evaporator heat exchange devices with different structures. The evaporator heat exchange device includes: an axial flow fan 4 , an evaporator 3 , and a compressor 2 . The evaporator 3 can be designed in different structural shapes, and placed in a cavity opposite to the axial flow fan 4 and the compressor 2 , and the compressor 2 is located in a closed space separating it from the evaporator 3 . And the enclosed space is formed by the arc partition plate 5 and the casing 6 arranged between the compressor 2 and the evaporator 3 . According to needs, the evaporator can be a V-shaped structure, and a pair is arranged symmetrically; the evaporator can also be an integral bent structure; the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com