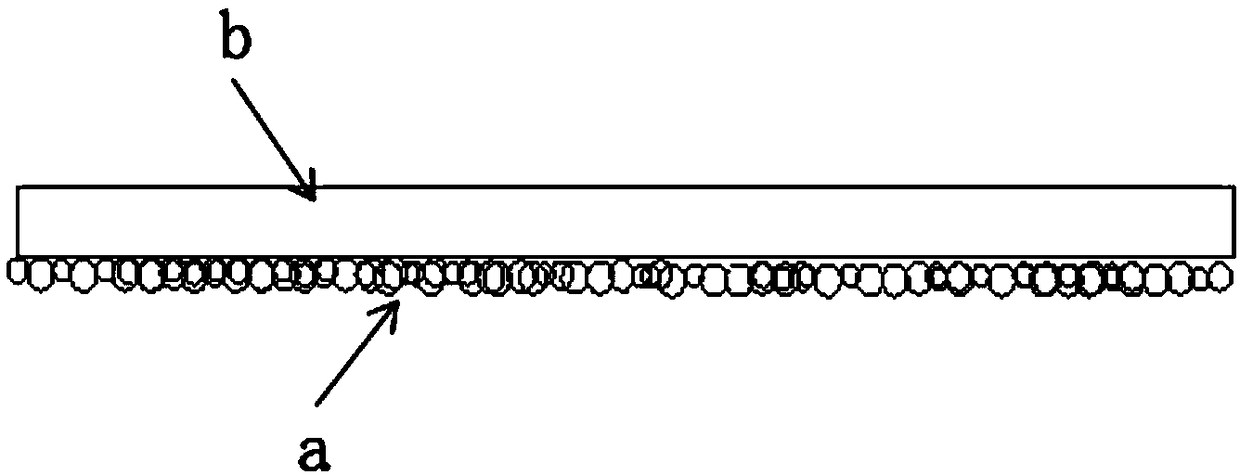

Diffusion sheet diffusion particle preparation device and method

A technology for diffusing particles and preparing devices, which is applied in the direction of spraying devices, spraying electric energy devices, electrostatic spraying devices, etc., and can solve the problems of high machining accuracy requirements for roller molds, low utilization rate of roller molds, and cumbersome procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

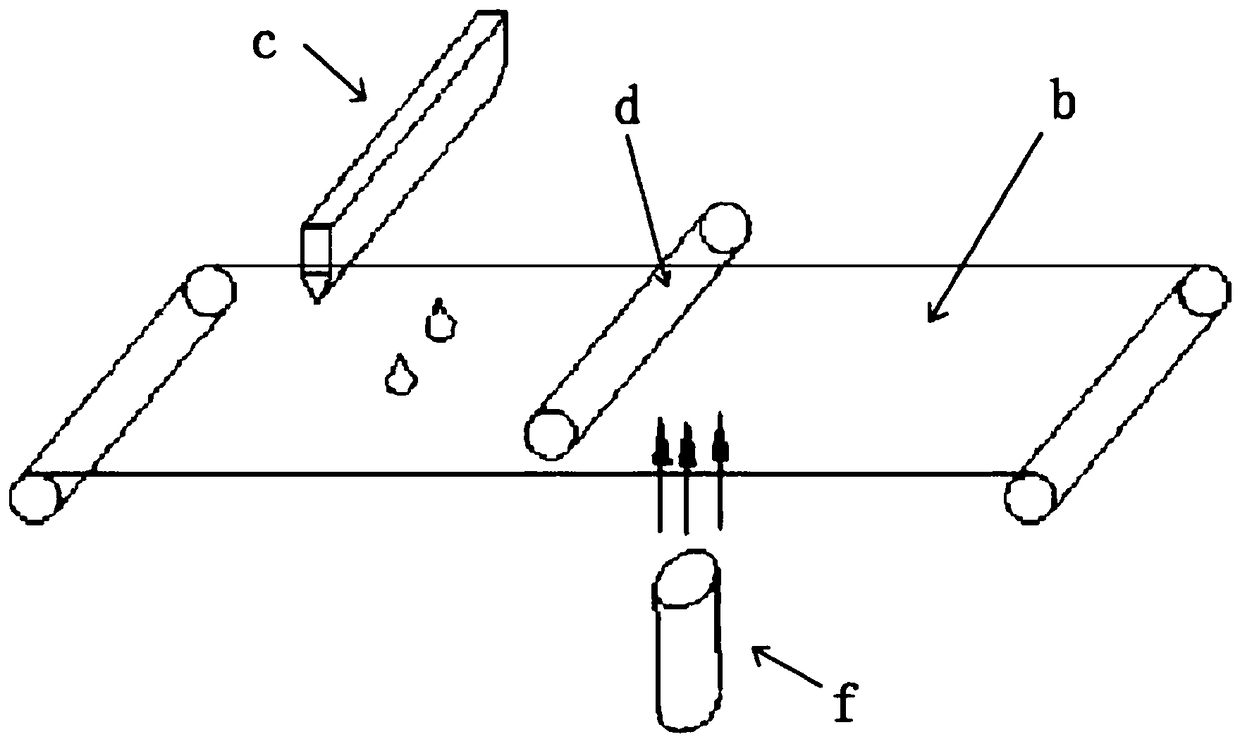

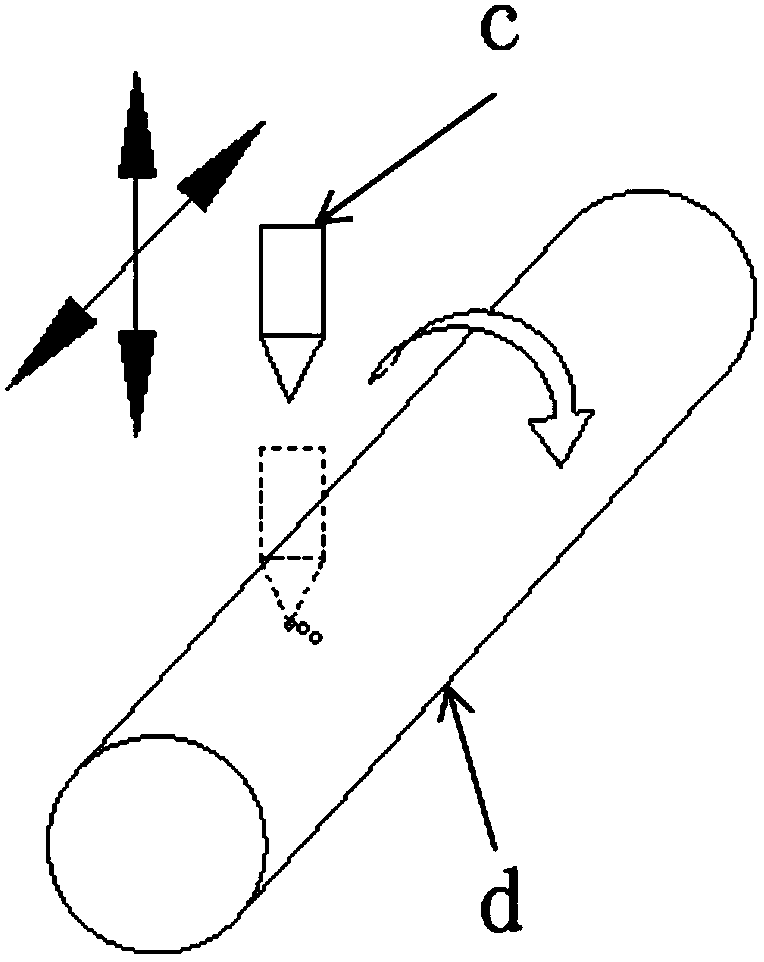

[0039] see Figure 5 to Figure 7 , The first embodiment of the present invention provides a device for preparing diffusion sheet diffusion particles. The device for preparing diffusion sheet diffusion particles includes an injection part, an atomization part and an electrical connection part.

[0040] The injection part includes a liquid supply tube 1 and a precision syringe pump 12, one end of the liquid supply tube 1 is connected to the injection head of the precision syringe pump 12, and the precision syringe pump 12 can provide pump pressure through Delivery in the liquid supply pipe 1.

[0041] The atomization part includes an electrostatic atomization nozzle 2 and a diffusion substrate 3 , and a solution 8 is stored inside the electrostatic atomization nozzle 2 . The electrostatic atomizing nozzle 2 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com