Quantitative evaluation method for beer packaging production line operation efficiency based on information entropy

A packaging production line and quantitative evaluation technology, which is applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of difficulty in ensuring reliability, more and more equipment, and large loss of equipment shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

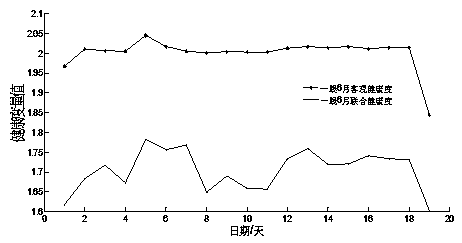

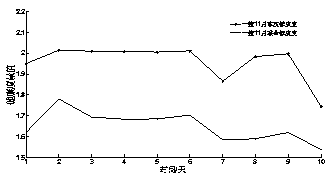

Examples

Embodiment 1

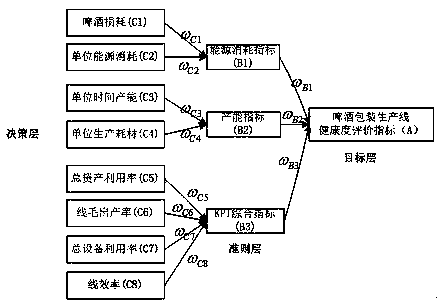

[0071] A quantitative evaluation method for the operation efficiency of beer packaging production line based on information entropy is mainly divided into five steps: the first step is to determine the reference variables for efficiency evaluation; the second step is to establish the matter-element evaluation model of beer packaging production line; the third step is to use AHP and entropy method to calculate the compound weight of the evaluation model; the fourth step: quantitative calculation and calculation of the health degree of the beer packaging production line; the fifth step is to establish the health degree prediction model of the beer packaging production line.

[0072] Step 1: Determine the evaluation reference variables, the calculation process is as follows:

[0073] The current beer packaging production line is mainly composed of a series of equipment such as bottle washing machine, wine filling machine, sterilizing machine, labeling machine and palletizing. Usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com