Method for evaluating high-temperature aging time of lithium ion battery

A lithium-ion battery, high-temperature aging technology, applied in the field of lithium-ion batteries, can solve the problems of no high-temperature aging time evaluation method, poor battery performance, and electric vehicle fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

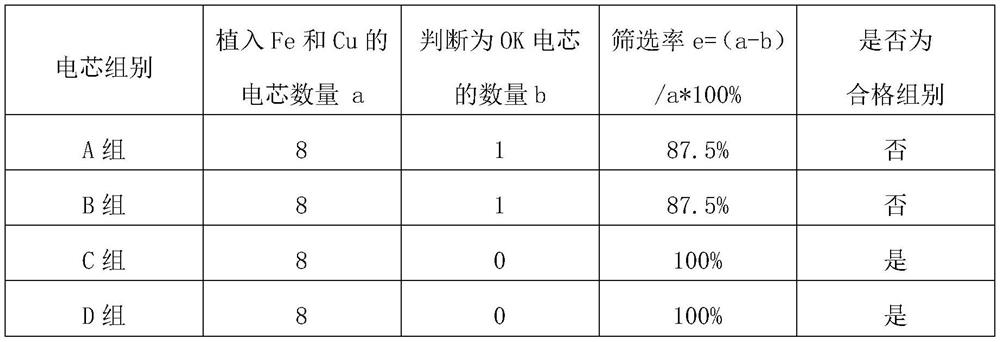

[0032] The following specific examples will further illustrate the present invention in detail.

[0033] A method for evaluating the high temperature aging time of a lithium ion battery provided by the present invention includes the following steps:

[0034] 1) Preparation of Fe and Cu metal particles

[0035] Add Fe and Cu particles with a particle size of 80-100 μm into a vial filled with absolute ethanol, respectively, and the volume ratio of Fe and Cu metal particles to absolute ethanol is 1:100 (the volume of metal particles is calculated by stacking volume) to obtain Fe / alcohol mixture, Cu / alcohol mixture;

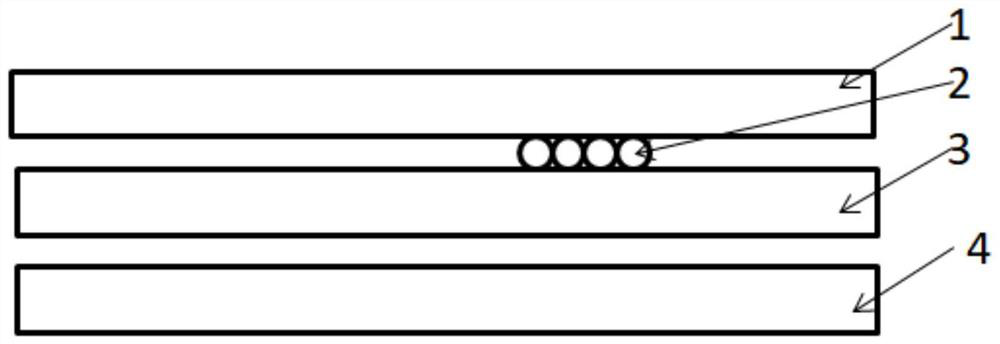

[0036] 2) Cell production

[0037] Take 4N bare cells of the same type that have just been wound as a group. In this embodiment, N=4, and N cells are taken from each group of bare cells to implant Fe particles, that is, shake the vial of Fe / alcohol mixture to make the The particles are evenly dispersed in the alcohol, and a drop of Fe / alcohol mixture is drawn with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com