Ignition transformer

A technology of transformers and high-voltage coils, which is applied in the direction of transformers, transformer/inductor cores, transformer/inductor components, etc. It can solve the problems of unfavorable batch production, difficult assembly, and complicated process, and achieve simple and economical assembly process. time, reliable insulation performance, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

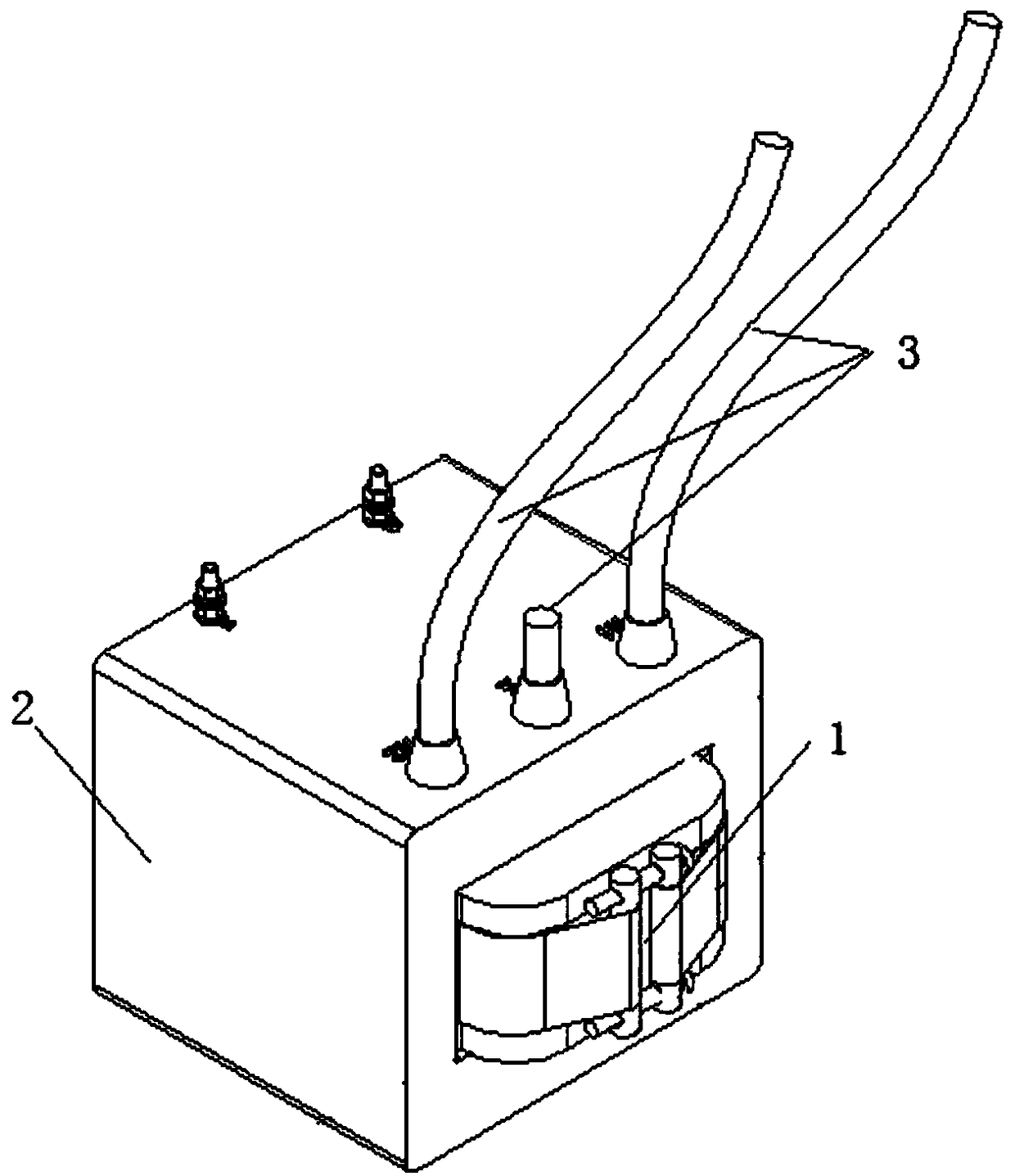

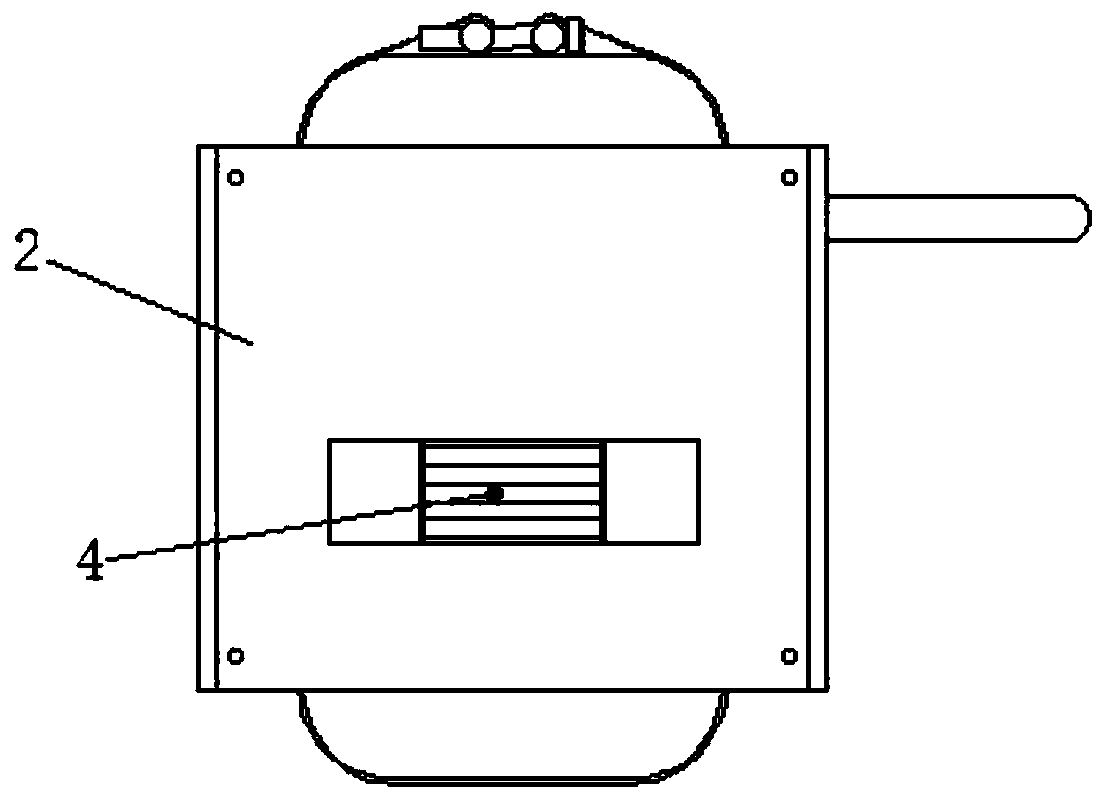

[0015] Such as figure 1 , figure 2 Shown is an ignition transformer, which includes an iron core 1 , a coil 2 fitted on the iron core 1 , a magnetic shunt 4 embedded in the coil 2 and three lead wires 3 arranged on the coil 2 .

[0016] The traditional ignition transformer iron core uses a single silicon steel sheet with a thickness of <0.5mm, which is cut and stamped several times, and then stacked and formed. The process is complicated and time-consuming. Therefore, in this embodiment, the iron core 1 is two SJ103-77 standard After the CD core is combined, the core 1 is tightened by packing steel strips and fasteners, while the SJ103-77 standard CD core can be purchased directly, which saves a lot of man-hours for multiple cutting and stacking of silicon steel sheets, and at the same time Parts and the like for assembling the iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com