Improved cigarette making machine and filter-tip connecting machine butting device

A technology of a docking device and a cigarette machine, which is applied in the directions of tobacco, cigarette manufacturing, and application, can solve the problems of high price, large size, complex structure, etc., and achieves the effects of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

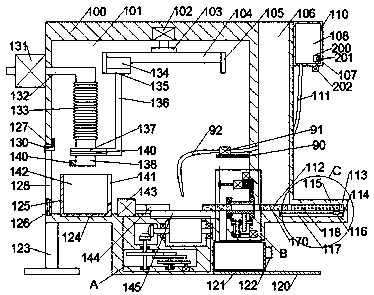

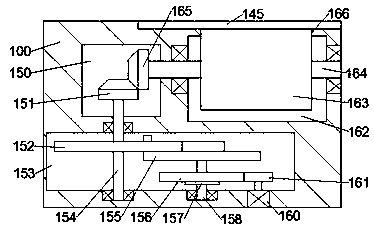

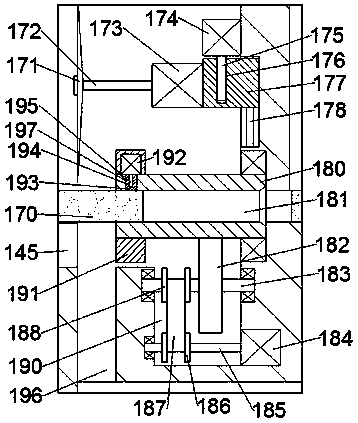

[0018] Combine below Figure 1-7 The present invention will be described in detail.

[0019] refer to Figure 1-7 , according to an embodiment of the present invention, the improved docking device between a cigarette maker and a mouthpiece machine includes a paper feeding device, a conveying device, a paper rolling device, a pasting device and an induction device, and the paper feeding device includes a device box 100, The device box 100 is provided with a working chamber 101, the left side of the device box 100 is fixed with an air suction pump 131, and the air inlet on the right side of the air suction pump 131 is sealed with a first air suction pipe 132. , the first air suction pipe 132 runs through the inner wall on the left side of the working chamber 101, enters the working chamber 101, extends to the right, and then extends downward. The bottom of the telescopic pipe 133 is sealed and connected to the second air suction pipe 138, the outer end surface of the second ai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap