Factory building dust removal device

A dust removal device and plant technology, which is applied in the direction of combined devices, dispersion particle separation, chemical instruments and methods, etc., can solve the problems of plastic dust being easily charged with static electricity, low dust removal efficiency, and high energy consumption, so as to reduce energy consumption, improve efficiency, The effect of reducing particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

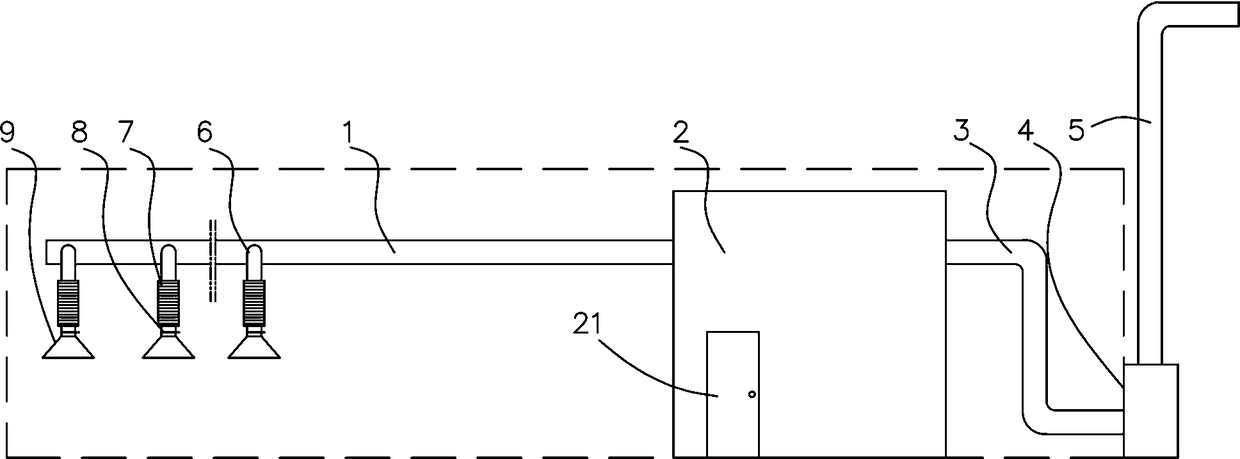

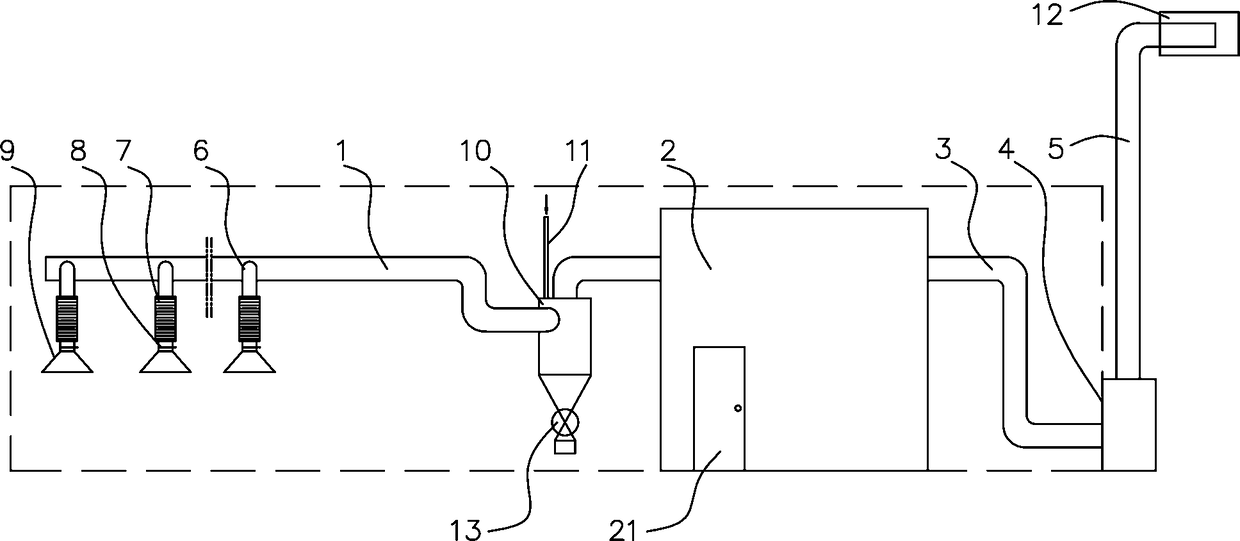

[0026] Such as Figure 1~4 Among them, a plant dust removal device, the first main pipe 1 is connected to the dust removal chamber 2, the dust removal chamber 2 is connected to the second main pipe 3, the second main pipe 3 is connected to the fan 4, and the fan 4 is connected to the exhaust pipe 5;

[0027] A plurality of branch pipes 6 are provided on the first main pipe 1, and a wind collecting hood 9 is provided at the end of the branch pipes 6;

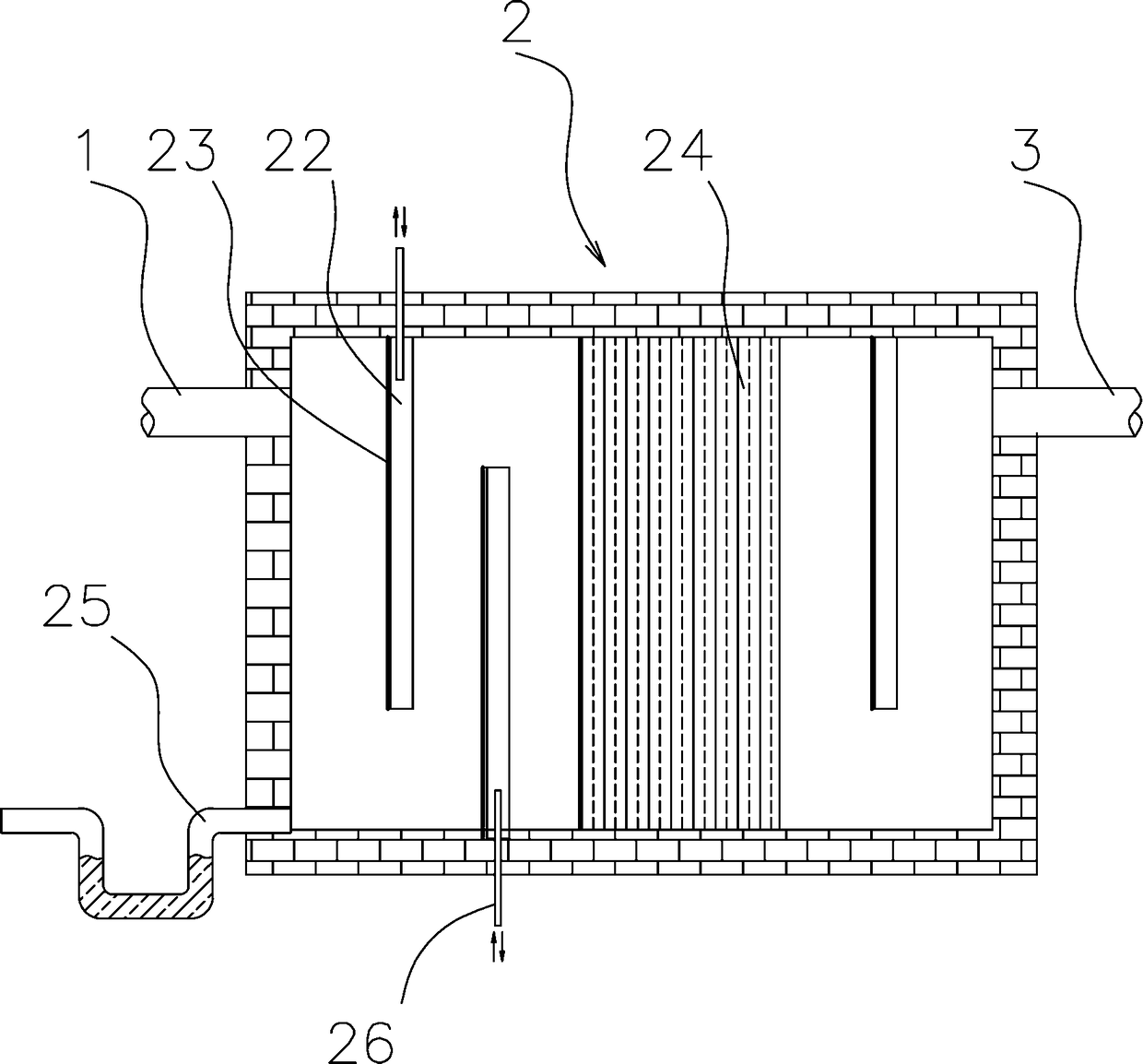

[0028] The dust removal chamber 2 is a closed space with an inner space of at least 1 cubic meter, and a baffle plate 22 for extending the wind path is provided in the closed space. For the factory buildings with less particulate matter content in the dust, the structure of the dust removal chamber 2 and the baffle 22 is enough to make the air meet the emission standard. In the position of the dust removal chamber 2, because the inner diameter suddenly increases, the air velocity slows down, and the particles are on the baffle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com