Disc-type transfer uniform-mixing platform

A transmission platform and disc-type technology, which is applied in mixers, transportation and packaging, shaking/oscillating/vibrating mixers, etc., can solve the problem that the mixing effect of the disc-type transmission mechanism is not obvious, and achieve the solution to the inconsistency of the mixing effect Obvious, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

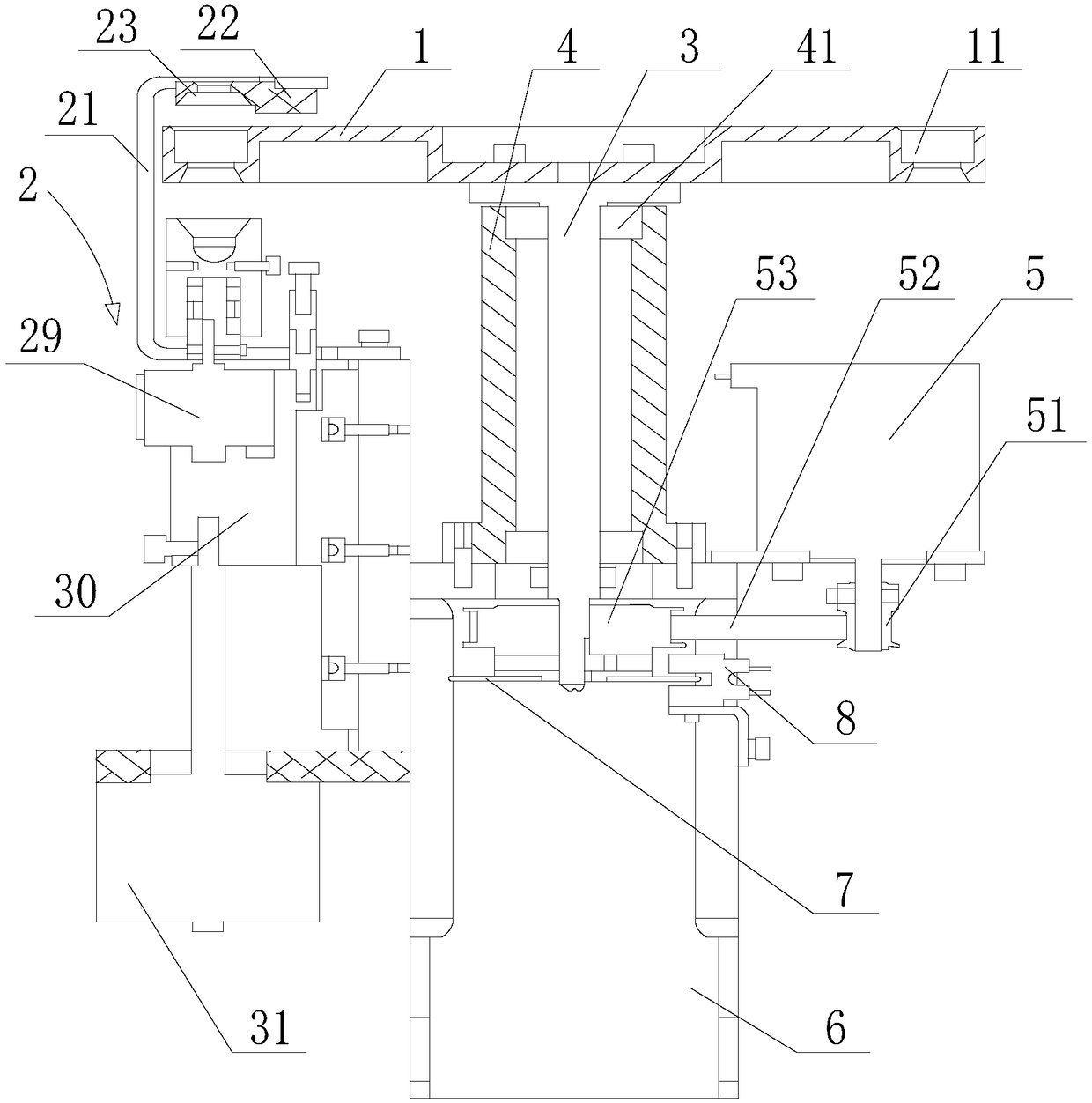

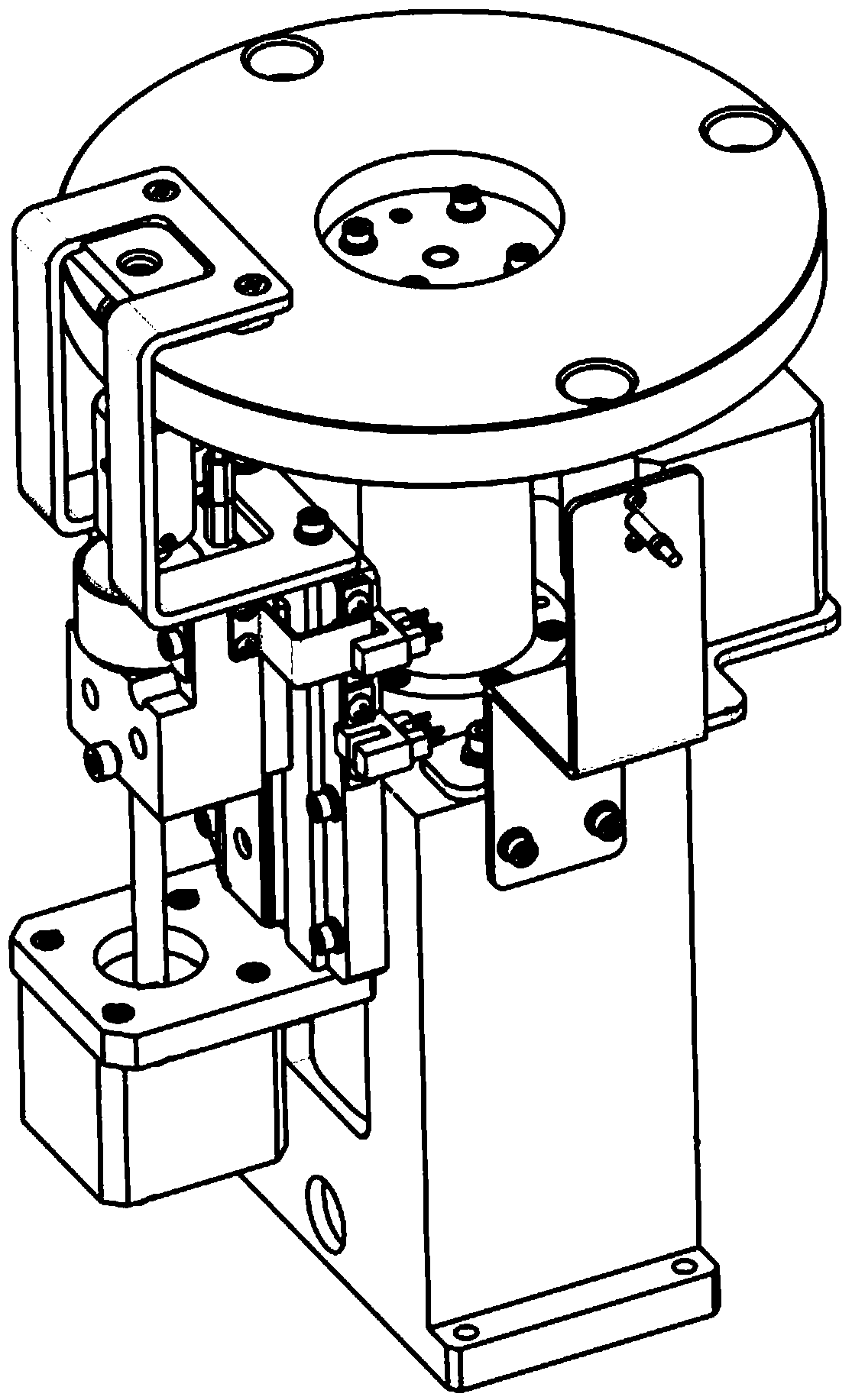

[0038] Such as Figure 1 to Figure 4As shown, a disk-type transmission and mixing platform includes a transmission platform, and the transmission platform includes a transmission disk 1, and the transmission disk 1 is driven to rotate by a rotating motor 5. Specifically, the transmission disk 1 is fixed by a rotating shaft 3 On the bearing mount 4, the two ends of the bearing mount 4 are provided with bearings 41, one end of the rotating shaft 3 is connected to the transmission disc 1, and the other end is connected to the transmission mechanism, and the rotating motor 5 is driven to rotate by the transmission mechanism The shaft 3 rotates, and the transmission mechanism includes a first synchronous pulley 53, a second synchronous pulley 51 and a synchronous belt 52, the first synchronous pulley 53 is connected with the rotating shaft 3, and the second synchronous pulley 51 is connected with the The rotating motor 5 is connected, the first synchronous pulley 53 and the second ...

Embodiment 2

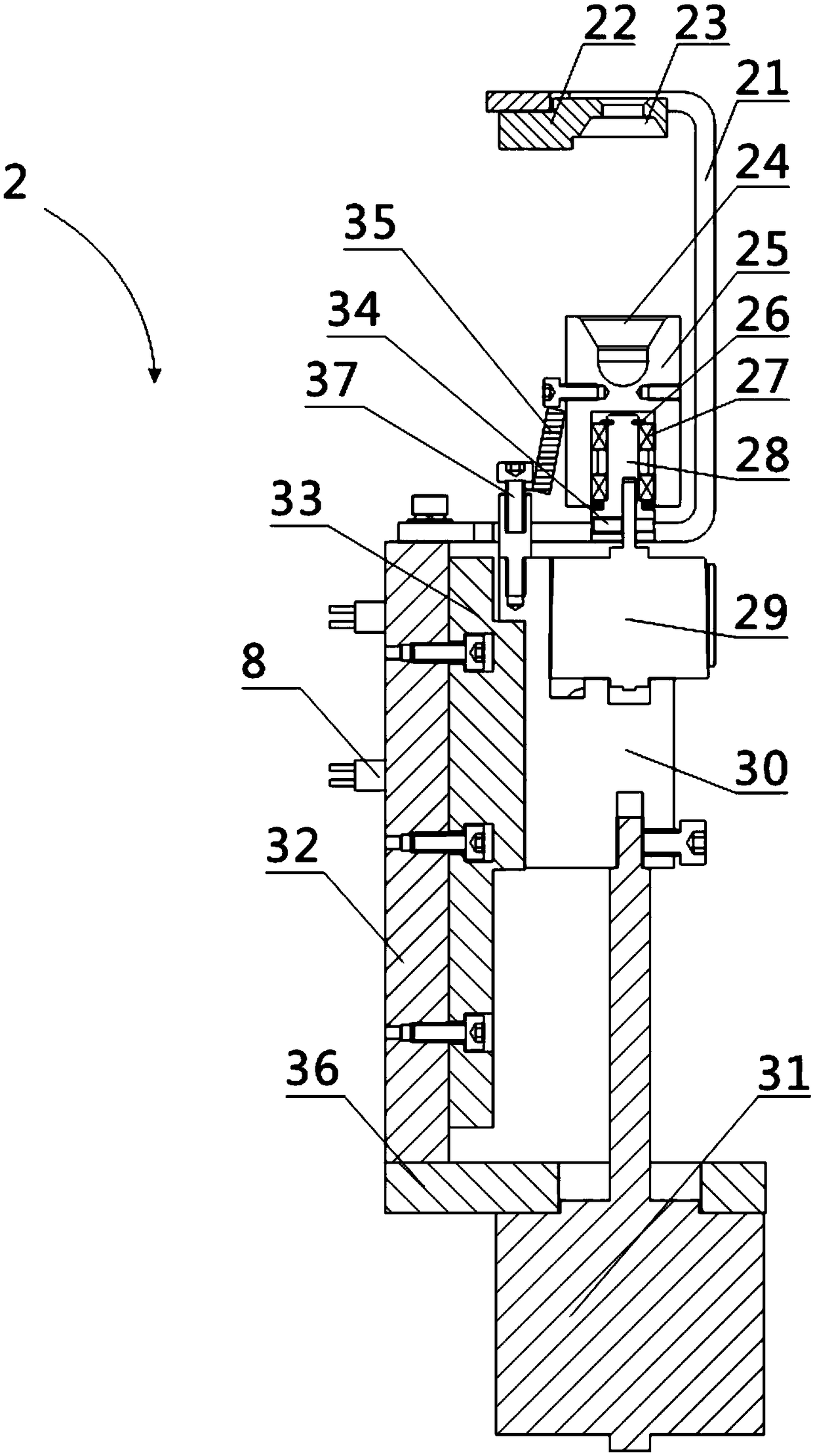

[0041] Such as Figure 1 to Figure 4 As shown, this embodiment is based on Embodiment 1, and the mixing mechanism 2 also includes a limit bracket 21, the limit bracket 21 is a U-shaped structure, and one side wall of the limit bracket 21 is arranged on the mixing motor 29 and the mixing cover 25, the other side wall is arranged above the transmission tray 1, and the limit bracket 21 is arranged on the inner side of the side wall above the transfer tray 1 to set a limit sleeve 22, and the limit sleeve 22 is set There is a second card slot 23 matched with the neck of the container.

Embodiment 3

[0043] Such as Figure 1 to Figure 4 As shown, this embodiment is based on Embodiment 1 or Embodiment 2, and the mixing mechanism 2 also includes a vertically installed linear guide rail 33, and the mixing motor fixing base 30 is installed on the slider of the linear guide rail 33, so The linear guide rail 33 is installed on the linear guide rail mounting plate 32, and the mixing motor fixing seat 30 is connected with the output shaft of the through-type stepping motor 31; the through-type stepping motor 31 is fixed on the fixing seat 36, and the The fixing seat 36 is arranged under the linear guide rail mounting plate 32 ; the transmission platform is fixed on the installation base 6 , and the linear guide rail mounting plate 32 is connected with the installation base 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com