Buffer piston cylinder for servo turret and servo turret

A technology for buffering pistons and turrets, applied in fluid pressure actuation system components, mechanical equipment, tool clamps, etc., can solve the problems of overheating and high movement speed of the piston cylinder, and achieve the purpose of reducing friction, solving overheating problems, and reducing heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

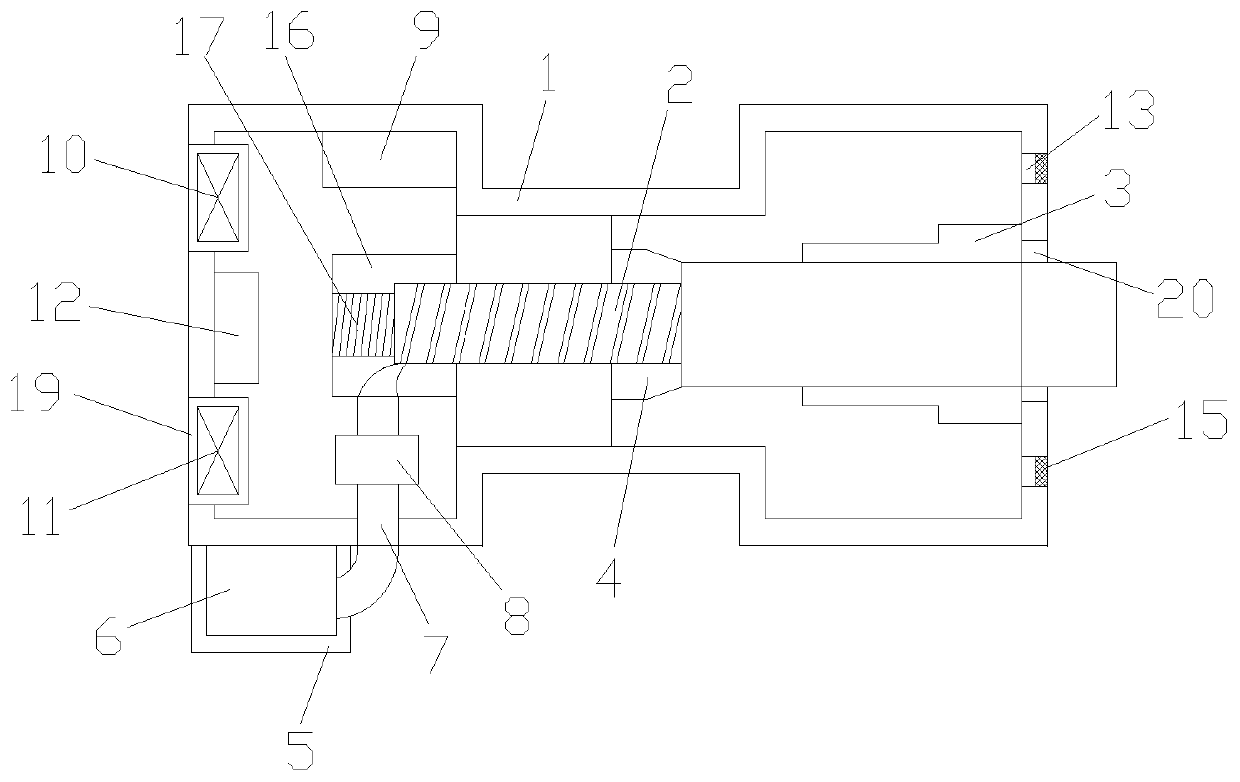

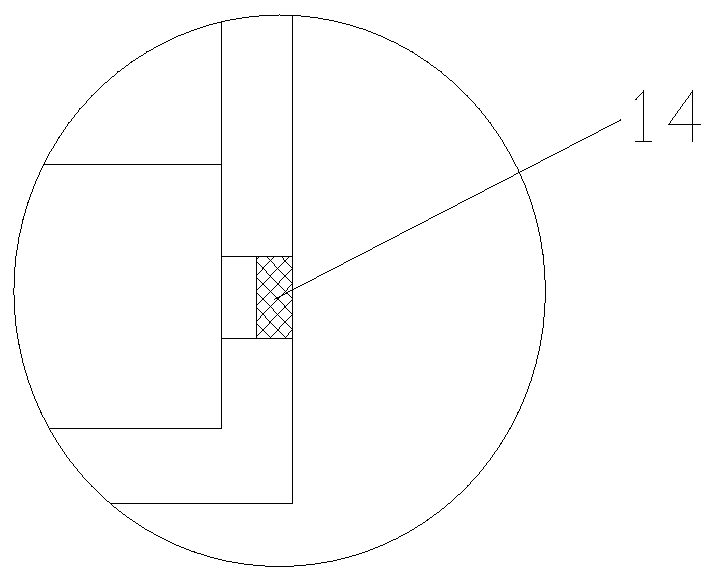

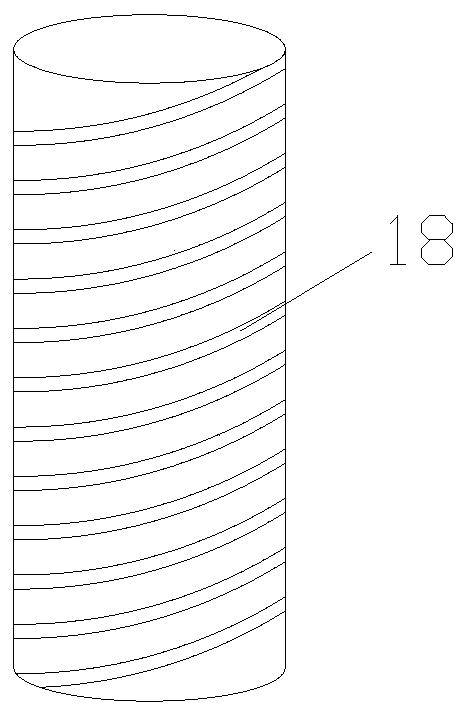

[0024] like figure 1 As shown, a buffer piston cylinder for a servo turret includes a housing 1 and a piston rod 2, a guide sleeve 3 is arranged inside the housing 1, the guide sleeve 3 wraps the piston rod 2, and the guide sleeve 3 and the The housing 1 is fixedly connected, the piston rod 2 is connected with the housing 1 through the guide sleeve 3, the piston rod 2 is provided with a buffer sleeve 4, the buffer sleeve 4 wraps the piston rod 2, and the buffer sleeve 4 and the piston rod 2 fixed connection, the housing 1 is provided with a fixed card seat 5, the fixed card seat 5 is fixedly connected with the housing 1, and the fixed card seat 5 is provided with a drip tank 6, and the drip tank 6 is embedded in the fixed card seat 5, the drip tank 6 is detachably connected to the fixed deck 5, and the drip tank 6 is connected with a drip tube 7, and the drip tube 7 is arranged through the fixed slot 5 and the shell 1, and the drip tube 7 has two The ends are respectively con...

Embodiment 2

[0027] like Figure 1-2As shown, a buffer piston cylinder for a servo turret includes a housing 1 and a piston rod 2, a guide sleeve 3 is arranged inside the housing 1, the guide sleeve 3 wraps the piston rod 2, and the guide sleeve 3 and the The housing 1 is fixedly connected, the piston rod 2 is connected with the housing 1 through the guide sleeve 3, the piston rod 2 is provided with a buffer sleeve 4, the buffer sleeve 4 wraps the piston rod 2, and the buffer sleeve 4 and the piston rod 2 fixed connection, the housing 1 is provided with a fixed card seat 5, the fixed card seat 5 is fixedly connected with the housing 1, and the fixed card seat 5 is provided with a drip tank 6, and the drip tank 6 is embedded in the fixed card seat 5, the drip tank 6 is detachably connected to the fixed deck 5, and the drip tank 6 is connected with a drip tube 7, and the drip tube 7 is arranged through the fixed slot 5 and the shell 1, and the drip tube 7 has two The ends are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com