Fly ash returning device, coal catalytic gasification system and method for returning fly ash to furnace

A gasifier and fly ash technology, which is used in gasification process, granular/powder fuel gasification, and the production of combustible gas, etc., can solve the problems of low carbon conversion rate, environmental pollution, and catalysts that are not effectively cured, and achieve Avoid pollution, improve stability, and achieve the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

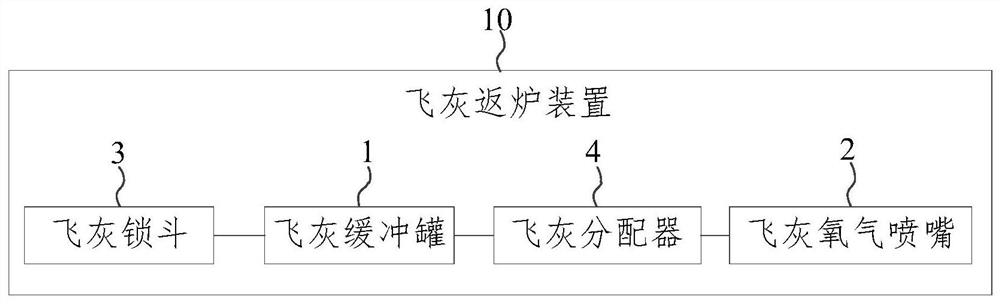

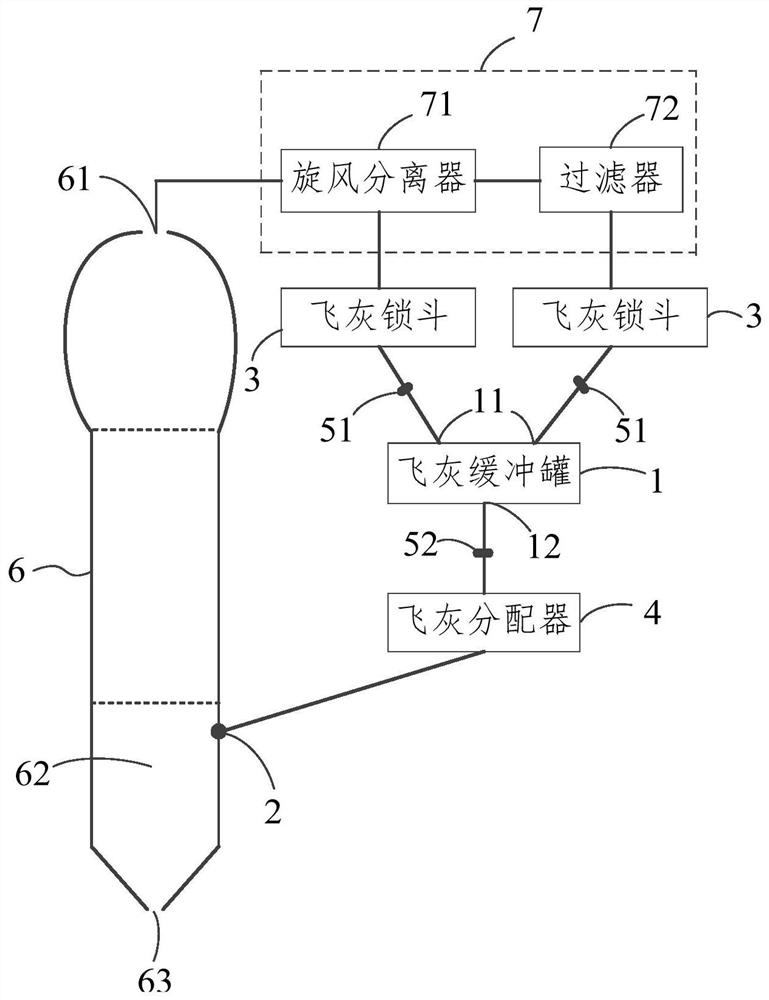

[0047] refer to figure 1 and figure 2 As shown, the present embodiment provides a fly ash returning device 10 . The fly ash returning device 10 includes: a fly ash buffer tank 1 and a fly ash oxygen nozzle 2 .

[0048] The fly ash buffer tank 1 has a fly ash input port 11 and a fly ash output port 12 , and the fly ash input port 11 is used for the fly ash generated in the gasifier 6 to enter the fly ash buffer tank 1 . Specifically, the fly ash input port 11 communicates with the gas discharge port 61 of the gasifier 6 , so that the fly ash in the gas discharged from the gas discharge port 61 enters the fly ash buffer tank 1 .

[0049] The gasifier 6 is specifically used for catalytic gasification of pulverized coal. In this embodiment, the gasifier 6 may be a fluidized bed gasifier, and the fluidized bed gasifier reacts the raw material gas with the gas during the gasification process. The contact between the pulverized coals is sufficient, and the gasification temperatur...

Embodiment 2

[0075] refer to Figure 1 to Figure 5 As shown, the present embodiment provides a coal catalytic gasification system, including a gasifier 6 and a fly ash returning device 10 .

[0076] The gasifier 6 has a gas discharge port 61, and the fly ash reflow device 10 communicates with the gas discharge port 61, so as to inject oxygen and fly ash in the gas to the high temperature melting zone 62 of the gasifier 6 through the fly ash reflow device 10 Inside, the fly ash undergoes a combustion reaction in the high-temperature melting zone 62 to achieve effective conversion of carbon in the fly ash and effective solidification of the catalyst, avoiding the situation that the fly ash containing the catalyst is directly discharged into the environment and pollutes the environment.

[0077] When specifically implemented, the coal catalytic gasification system further includes a gas separation device 7, the gas separation device 7 has a gas inlet and a fly ash discharge port, the gas inle...

Embodiment 3

[0080] This embodiment also provides a method for returning the fly ash to the furnace, and the method can be performed by part or all of the fly ash returning device 10 provided in the above-mentioned embodiment, so as to realize the effective utilization of the fly ash and realize the carbon in the fly ash. efficient conversion of the catalyst and effective curing of the catalyst.

[0081] combine Figure 1 to Figure 6 As shown, the method includes:

[0082] S101 , passing the fly ash generated in the gasifier 6 into the fly ash buffer tank 1 .

[0083] In specific implementation, the gas can be firstly transported to the gas separation device 7, and the gas is separated by the gas separation device 7 to obtain fly ash by separation.

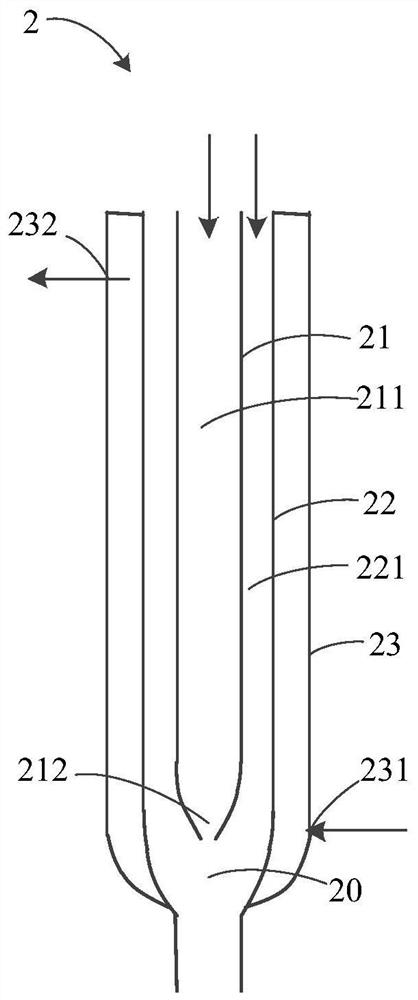

[0084] S102 , passing the fly ash in the fly ash buffer tank 1 into the fly ash oxygen nozzle 2 .

[0085] S103 , injecting oxygen and fly ash into the melting zone 62 of the gasifier 6 through the fly ash oxygen nozzle 2 , so that the fly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com