Automatic urine analyzer test strip screening mechanism

A urine analyzer and test strip technology, which is applied in the field of medical devices, can solve the problems that the friction force between the guide pieces cannot be completely consistent, the sorting speed is slow, and the test volume cannot be adapted to large hospitals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The test strip screening mechanism of a fully automatic urine analyzer will be further described in detail below in combination with the embodiments and the accompanying drawings.

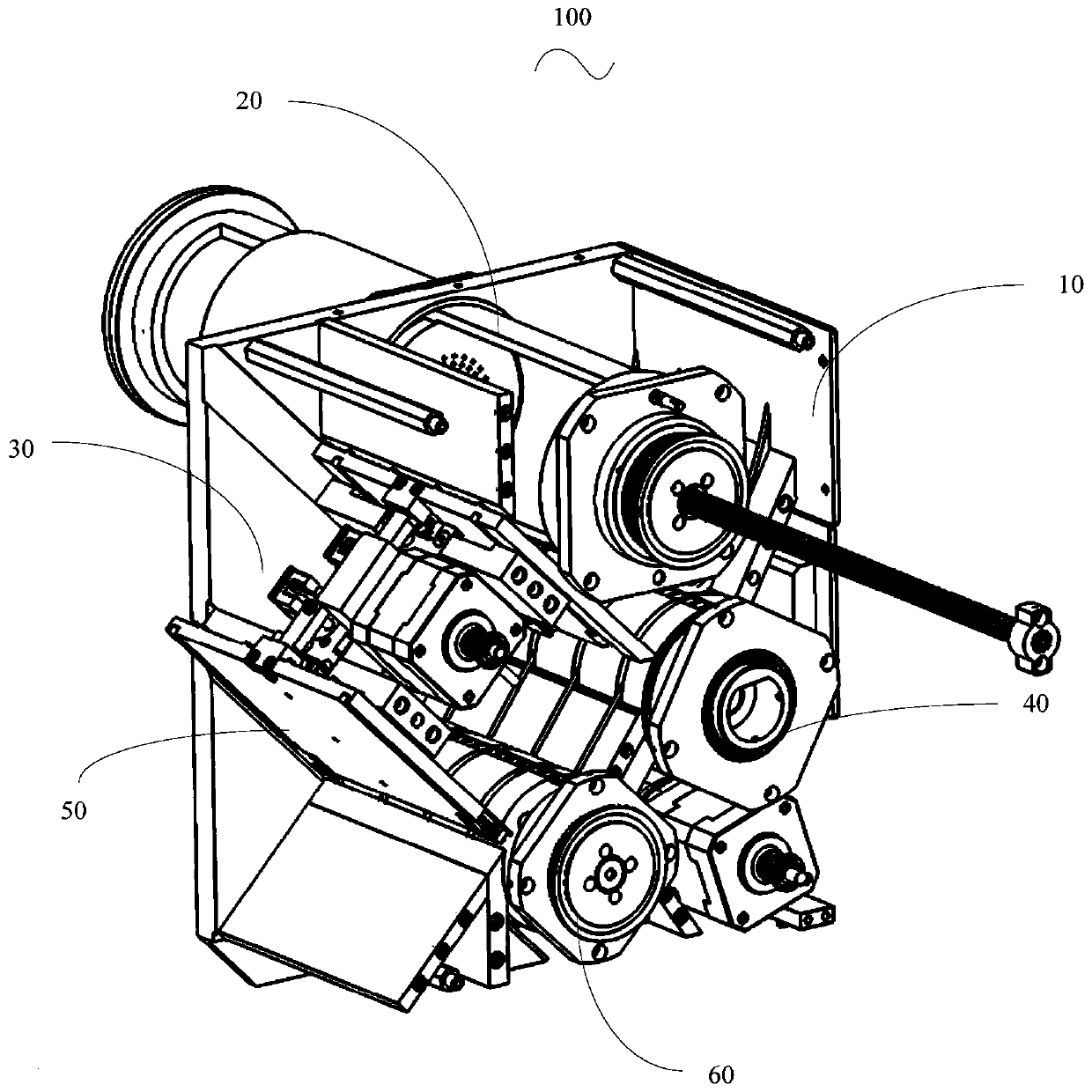

[0035] see figure 1 , a fully automatic urine analyzer test strip screening mechanism 100 according to an embodiment mainly includes a bracket body 10, a test paper tube mechanism 20, a first-level opening mechanism 30, a sorting mechanism 40, a second-level opening mechanism 50, and a turning mechanism 60.

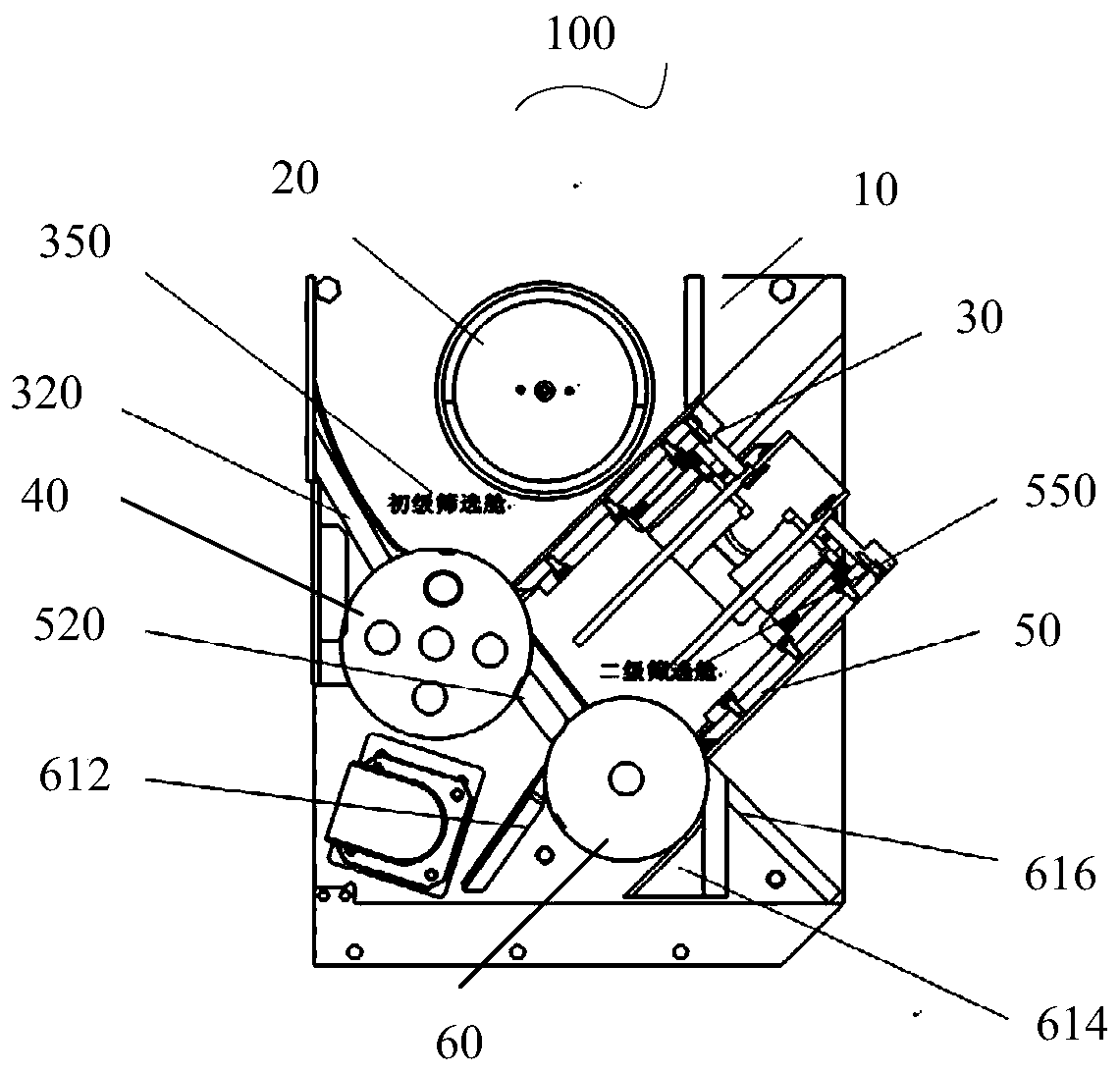

[0036] see figure 2 , in one embodiment, the bracket body 10 includes a first frame 110 and a second frame 120 disposed opposite to each other, and a support column 130 is disposed between the first frame 110 and the second frame 120 .

[0037] In one embodiment, the number of support columns 130 is seven, and in other embodiments, the number of support columns 130 can also be adjusted according to actual conditions.

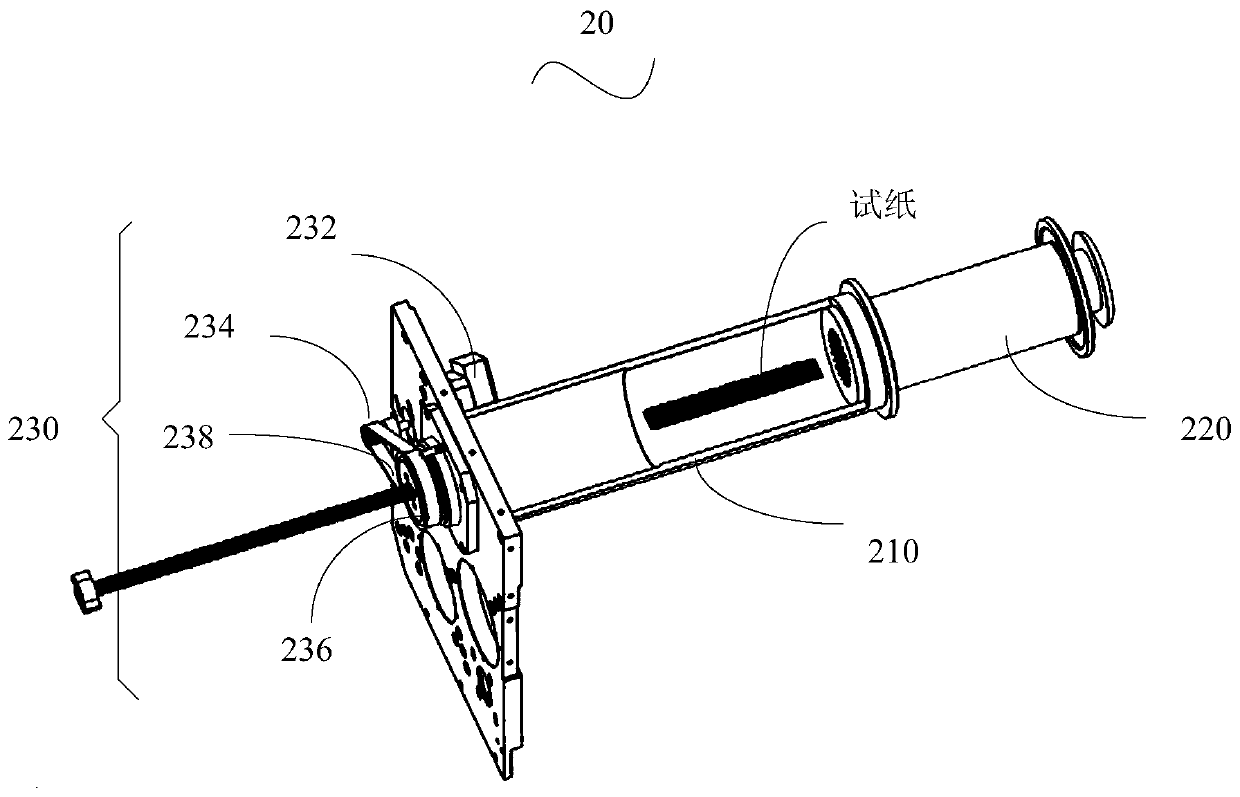

[0038] see image 3 , in one embodiment, the test paper cartrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com