Self-locking type manual pressure machine

A press, self-locking technology, applied in the direction of presses, stamping machines, metal processing, etc., can solve the problems of unfavorable workpiece alignment molded workpieces, no self-locking function, unable to maintain pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

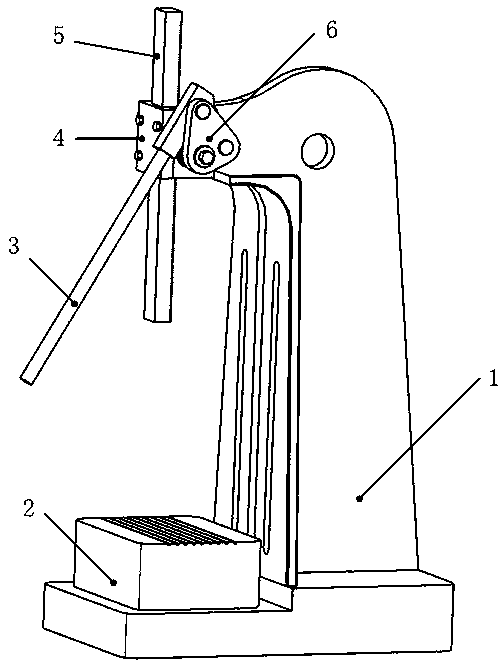

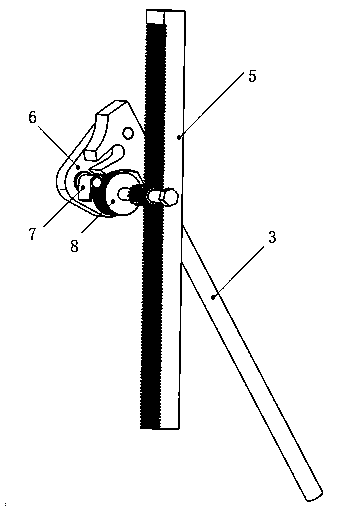

[0015] A self-locking manual press mainly consists of a body 1, a workbench 2, a pressure rod 3, a pressure head 5, a connecting plate 6 and some transmission mechanisms.

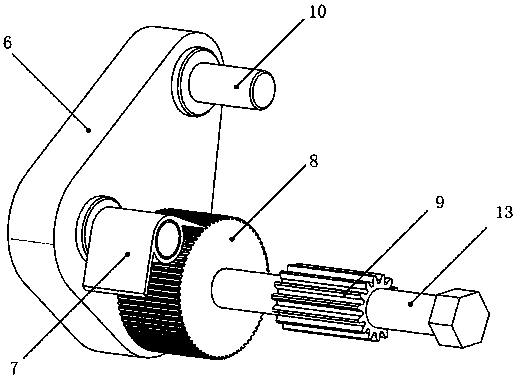

[0016] The workbench 2 is placed on the body 1, the surface of the workbench 2 is set with a T-shaped groove for positioning connection, the pressure head 5 is connected with the gear of the body 1 through the pressure plate 4, and the back of the pressure head 5 is a trapezoidal tooth surface; the gear 9 is fixedly connected on the main shaft 13, and the main shaft 13 is installed on the fuselage 1; the ratchet 8 is set on the outside of the main shaft 13, and is fixedly connected with the main shaft 13; the pawl 7 is hinged with the pin rod 11 on the connecting plate 6, and the connecting plate 6 and The main shaft 13 is hinged, the pressure rod 3 is hinged with the pin 10 on the connecting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com