Automobile part manufacturing mold

A technology for making auto parts and molds, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc. It can solve the problems of single function of the mold top tightening forming device, and the rotation stability of the mold cannot be formed at the bottom, so as to prevent slipping and facilitate removal. The effect of taking and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

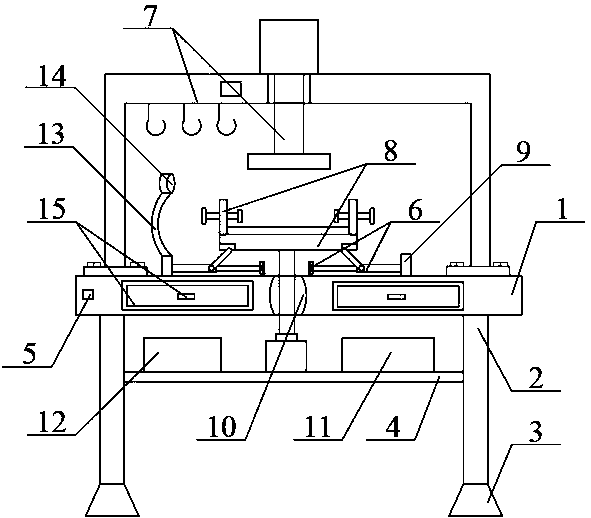

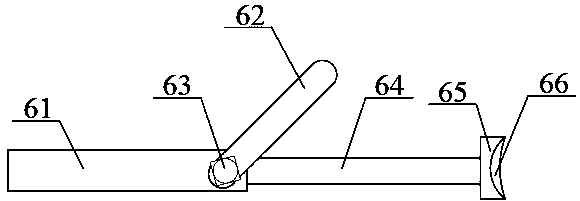

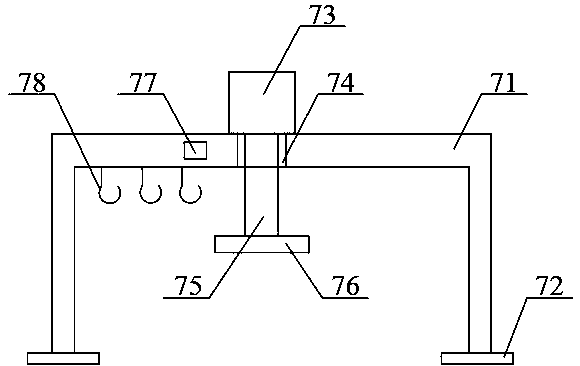

[0036] as attached figure 1 to attach figure 2 As shown, the present invention provides a mold for automobile parts manufacturing, including an automobile parts manufacturing mold workbench 1, a support column 2, a shock-absorbing protective foot pad 3, a horizontal object board 4, a rotary control switch 5, a telescopic fixed card device 6, and an inverted U Type support frame device 7, rotatable weight fixing seat device 8, mounting block 9, bearing 10, finished car parts storage box 11, auto parts waste product storage box 12, stainless steel elbow 13, storage snap ring 14 and storage drawer 15, all The support columns 2 are respectively bolted to the four corners of the lower surface of the mold workbench 1 for automobile parts manufacturing; the shock-absorbing protective foot pads 3 are socketed at the lower end of the support columns 2 to play the role of shock absorption and anti-skid; Said horizontal object plate 4 is connected with the support column 2 and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com