Rapid rust removing machine for channel steel

A rust remover and fast technology, which is applied to the parts of grinding machine tools, grinders, grinding drives, etc., can solve the problems of low rust removal efficiency, easy rusting of channel steel, high labor intensity, etc., to speed up rust removal. Efficiency, reduce usage, save power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

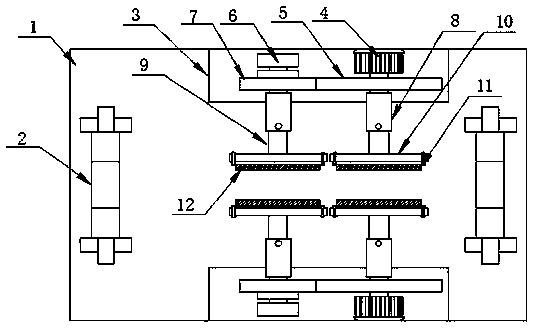

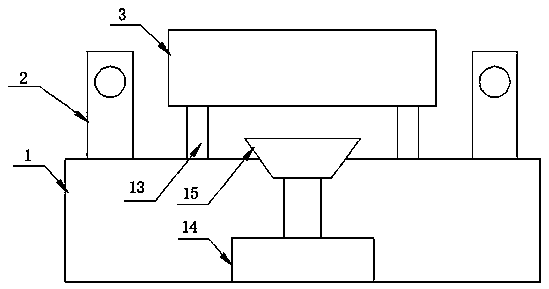

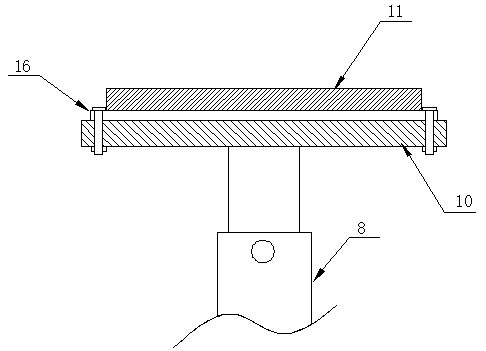

[0016] Such as Figure 1-3 As shown, the present invention discloses a quick derusting machine for channel steel, comprising: a base 1, a first wire brush 11, and a second wire brush 12, characterized in that: the two ends of the top of the base 1 are respectively provided with a shelf 2. The placement rack 2 is provided with a placement slot, and the two sides of the top of the base 1 are respectively provided with a dust cover 3, and the dust cover 3 is provided with a derusting motor 4, and the derusting motor 4 has its own The motor shaft is rotatably connected with a driving gear 5, and the driving gear 5 is engaged with a driven gear 7, and the driven gear 7 is rotatably connected with a rotating shaft, and one end of the rotating shaft is provided with a bearing seat 6, and the other end of the rotating shaft One end is provided with the second telescopic tube 9, which is convenient to adjust the distance of the wire brush according to the size of the channel steel, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com