Adjustable eddy current spraying pole-climbing robot

A vortex jetting and adjustable technology, applied in the field of pole-climbing robots, can solve problems such as insufficient water flow, weight imbalance, backward technology, etc., and achieve the effect of saving energy loss and avoiding weight imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

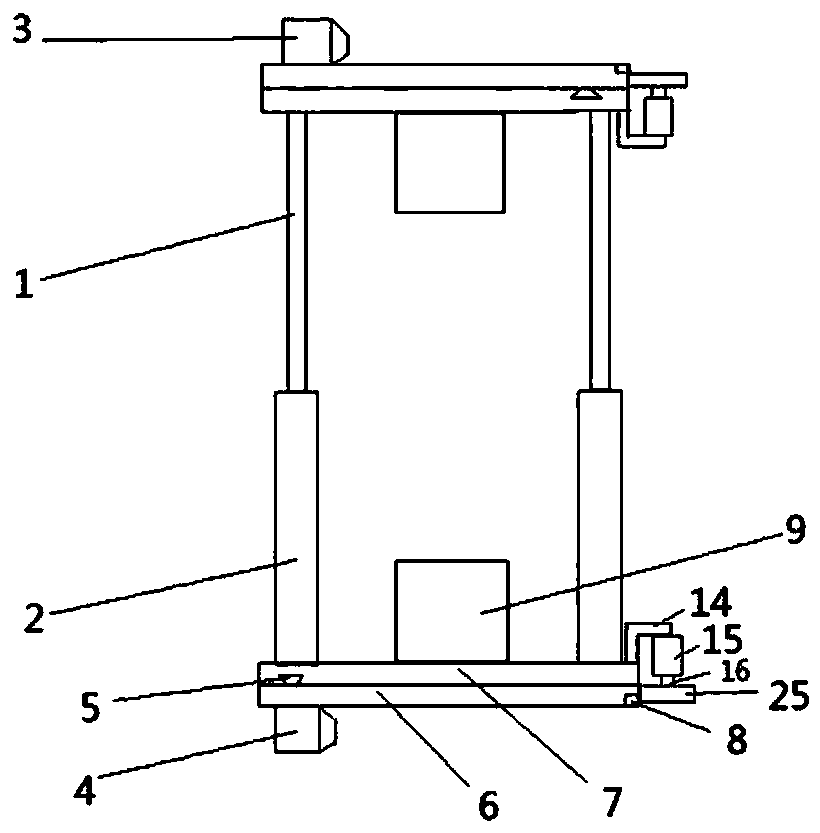

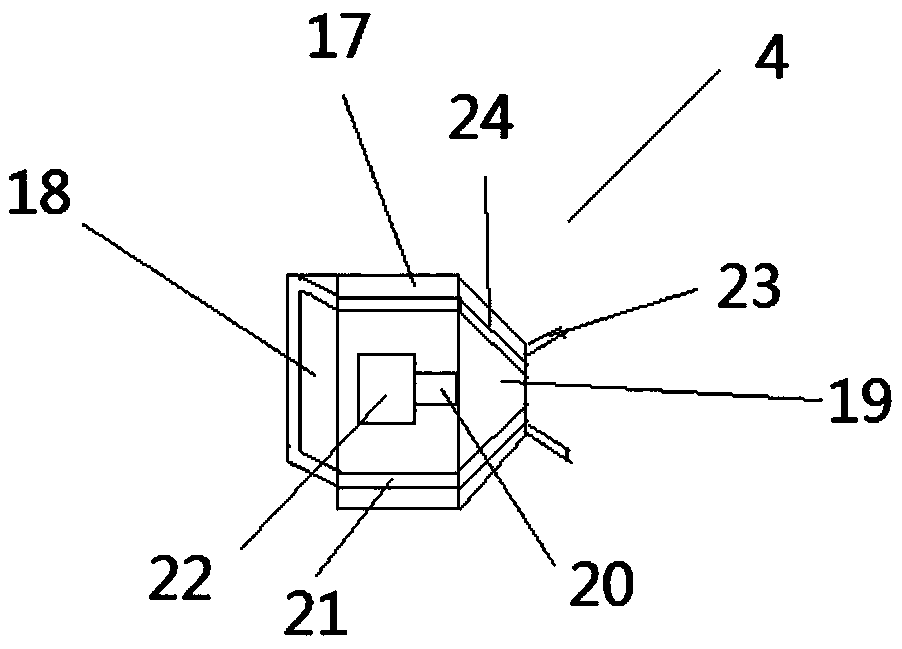

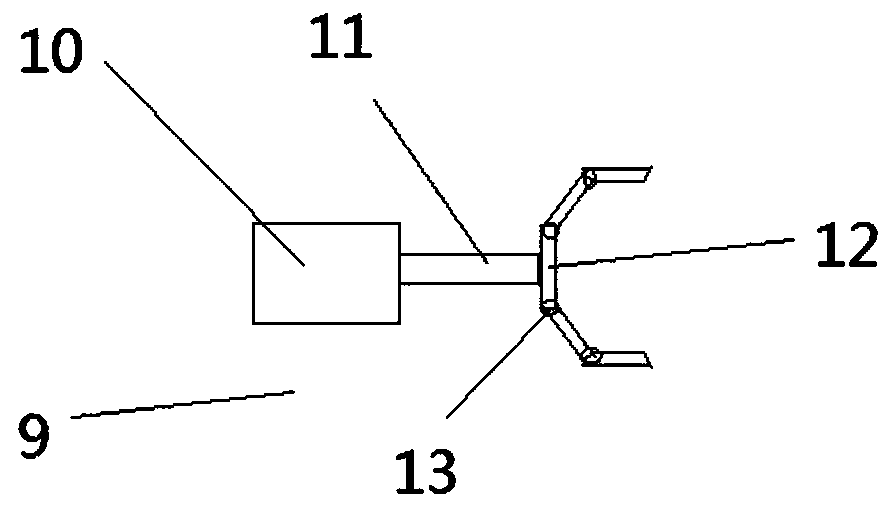

[0033] As shown in the figure: an adjustable vortex spray rod climbing robot, including piston rod, cylinder, upper cleaning structure, lower cleaning structure, trapezoidal slider, water storage structure, bracket seat, water injection port, clamping structure, clamping Cylinder, clamping lever, multi-section jaw, pivot joint, bracket, motor, motor output shaft, cleaning block, connection block, nozzle, nozzle motor shaft, annular flow channel, nozzle motor, nozzle flap, spiral flow Road, pinion, and clamping structure; the cylinder and the piston rod are connected between the two bracket seats, and the up and down movement is realized through the expansion and contraction of the cylinder tube and piston rod. The lower part of the upper bracket seat is connected with the upper part of the lower bracket seat with a clamping structure The upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com