A processing technology of high-elastic and breathable three-dimensional mesh

A processing technology and three-dimensional technology, which is applied in the processing technology field of high-elasticity and breathable three-dimensional mesh cloth, can solve the problems of affecting production efficiency, easy deformation of polyester fiber yarn group, elastic effect of mesh cloth, poor breathability and air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

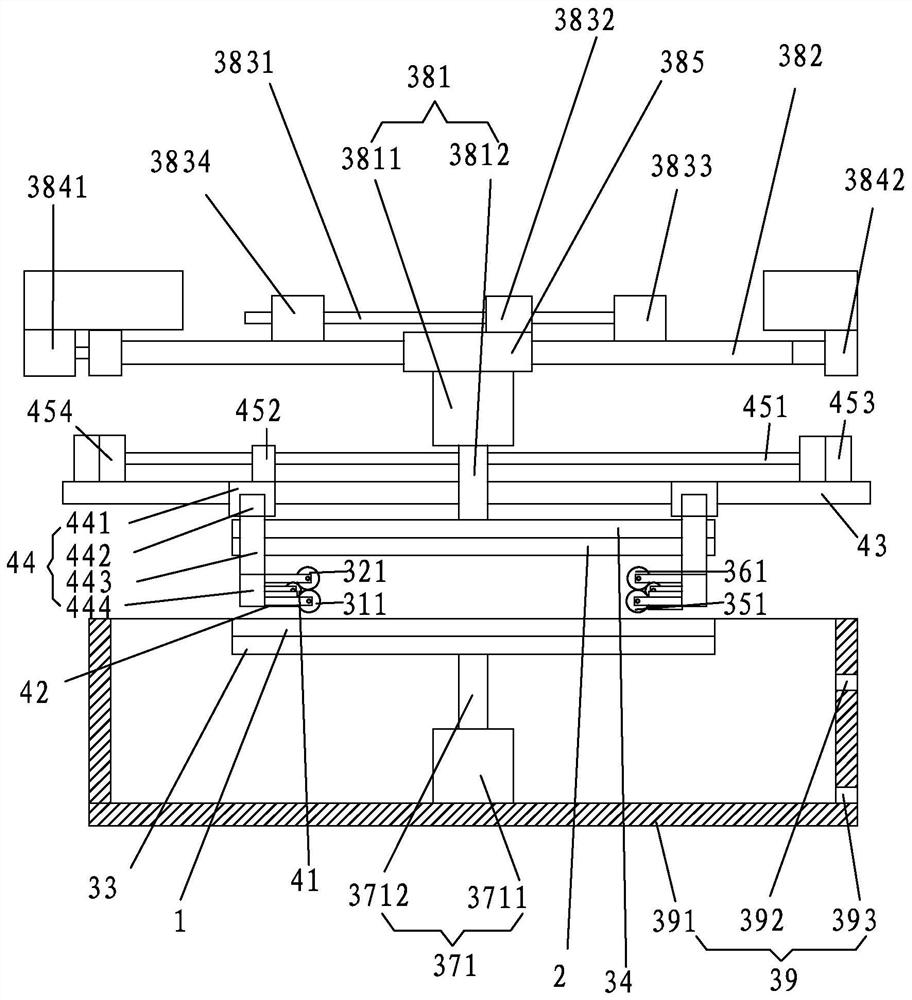

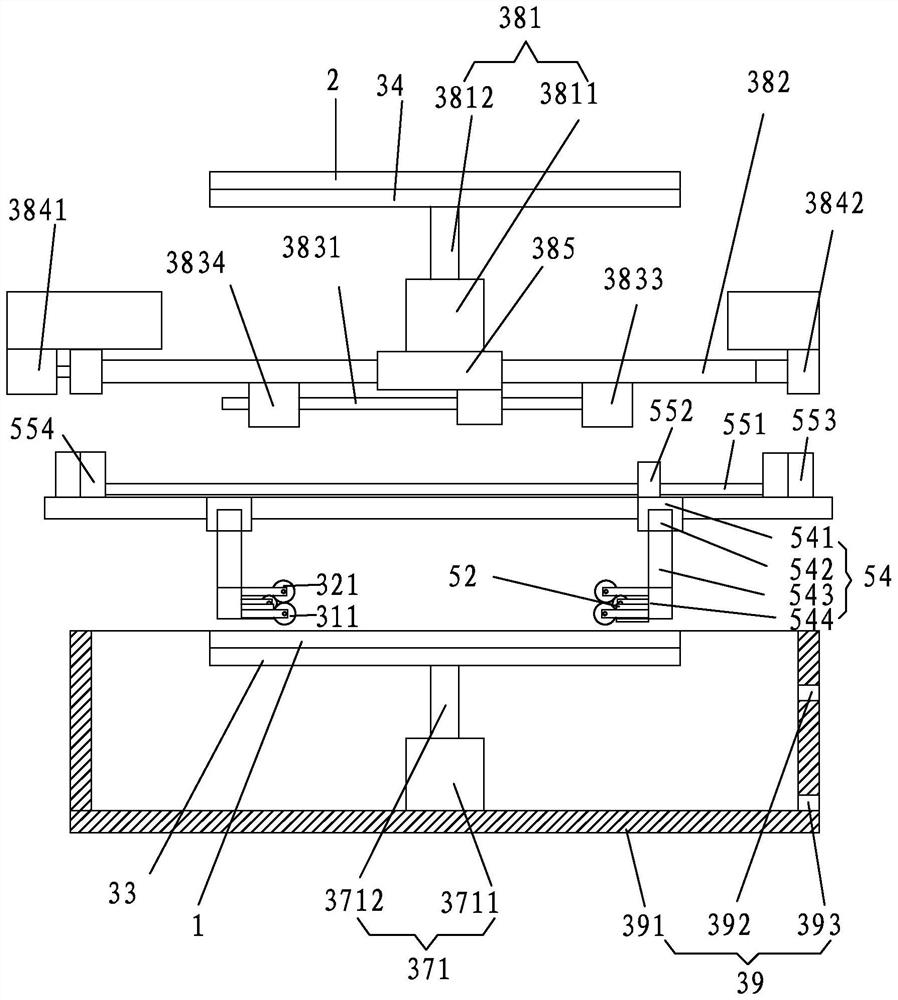

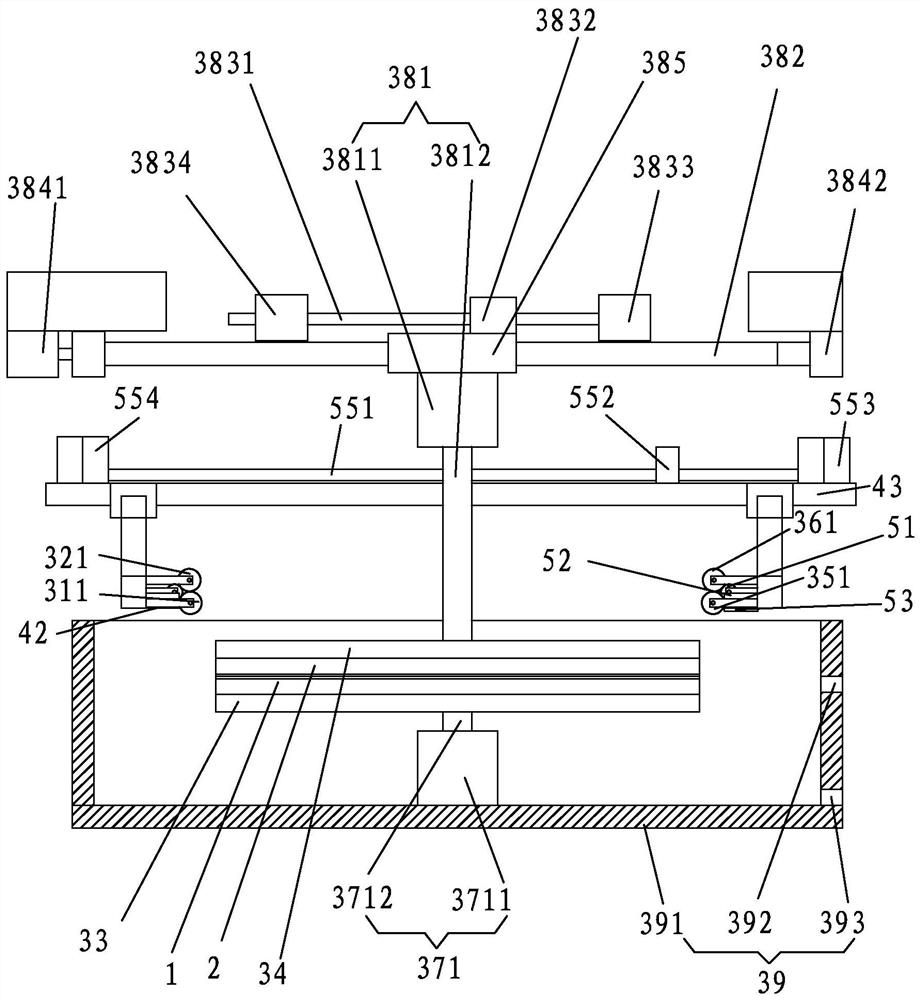

[0056] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

[0057] The processing technology of a kind of high-elastic breathable three-dimensional net cloth of the present invention, as Figure 1-4 shown, including the following steps:

[0058] (1) make the first mesh layer 6 and the second mesh layer 7 with mesh;

[0059] (2) plane fixing is carried out to the first mesh cloth layer 6 and the second mesh cloth layer 7;

[0060] (3) brushing melted rubber on the surface of at least one of the first mesh layer 6 and the second mesh layer 7;

[0061] (4) When the melted rubber is in a melted state, the first mesh layer 6 and the second mesh layer 7 are correspondingly bonded together, and bonded together by the melted rubber;

[0062] (5) When the melted rubber is in a melted state, the first mesh layer 6 and the second mesh layer 7 are separated by a set distance so that the melted rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com