Fire-resistant cloth drying device

A technology of drying device and refractory cloth, which is applied to general parts of printing machinery, printing, printing presses, etc., can solve problems such as dislocation, easy wrinkling of refractory cloth, and reduced production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

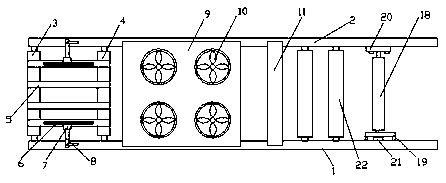

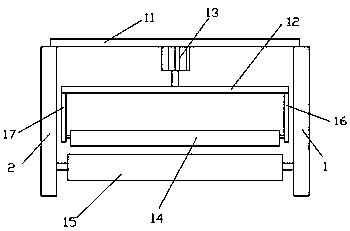

[0025] Such as figure 1 , 2 As shown, the technical solution of the present invention is: a drying device for refractory cloth, including a front plate 1 and a rear plate 2, and a limit mechanism is sequentially arranged between the front plate 1 and the rear plate 2 along the direction of refractory cloth transmission. , drying mechanism, flattening mechanism and receiving mechanism,

[0026] The limiting mechanism includes a left limiting roller 3, a right limiting roller 4, a conveyor belt group, a front limiting member and a rear limiting member, and the two ends of the left limiting roller 3 pass through the first front limiting roller respectively. shaft and the first rear limit shaft are arranged on the front plate 1 and the rear plate 2, and the joints between the first front limit shaft and the first rear limit shaft and the front plate 1 and the rear plate 2 are provided with first The limit bearing, the first rear limit shaft passes through the back plate 2, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com