Fiber dyeing device for spinning

A dyeing device and fiber technology, which is applied in the processing of textile materials, equipment configuration for processing textile materials, textiles and papermaking, etc., can solve problems such as processing, affecting production efficiency, and disadvantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

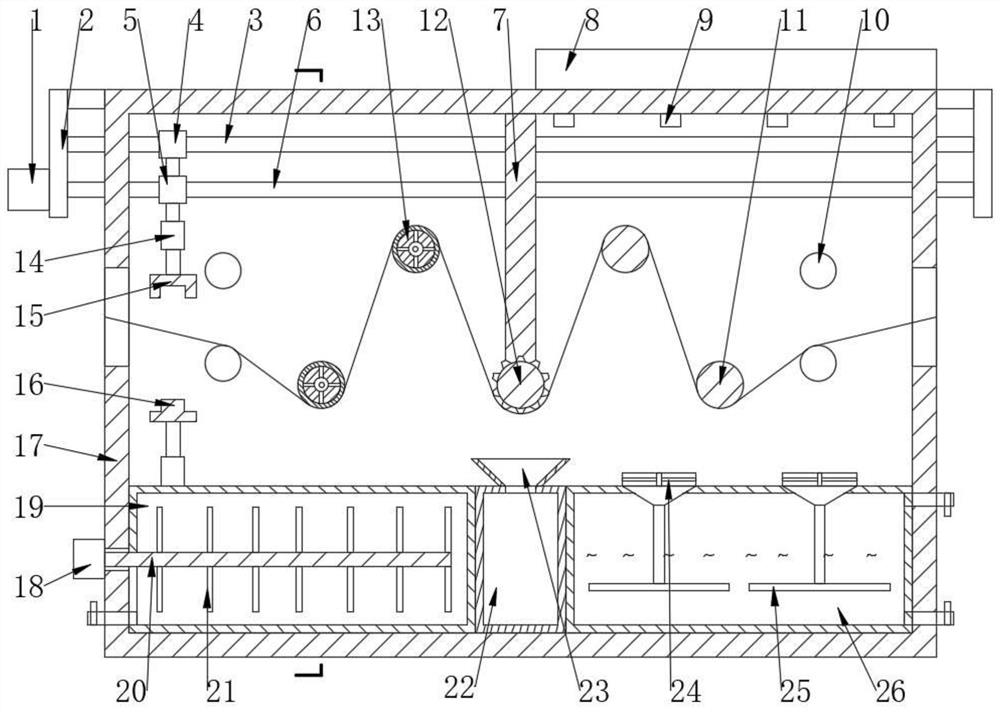

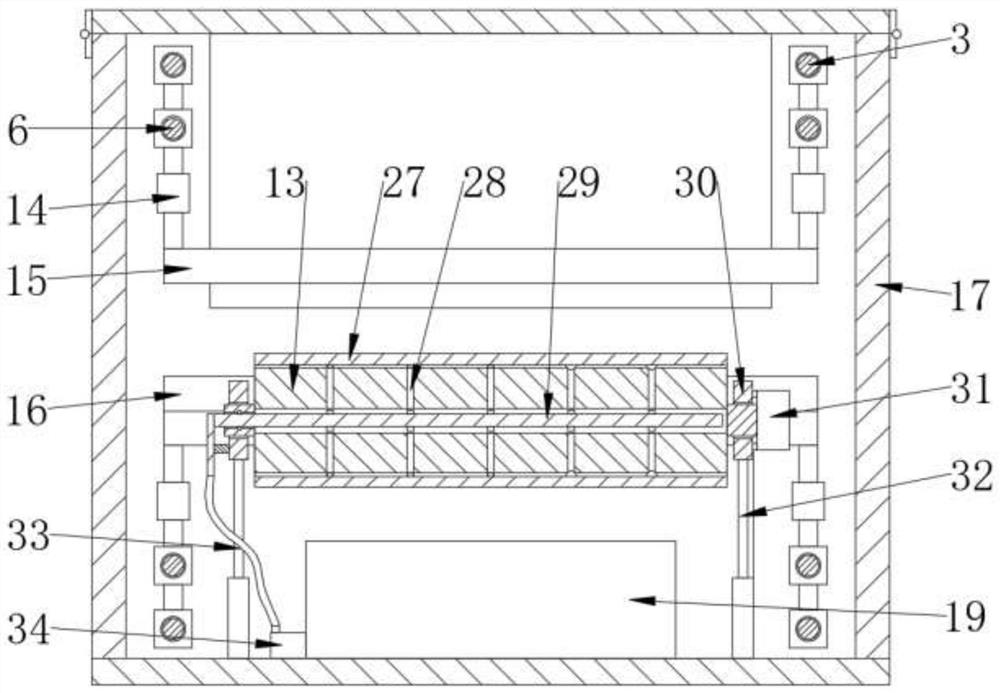

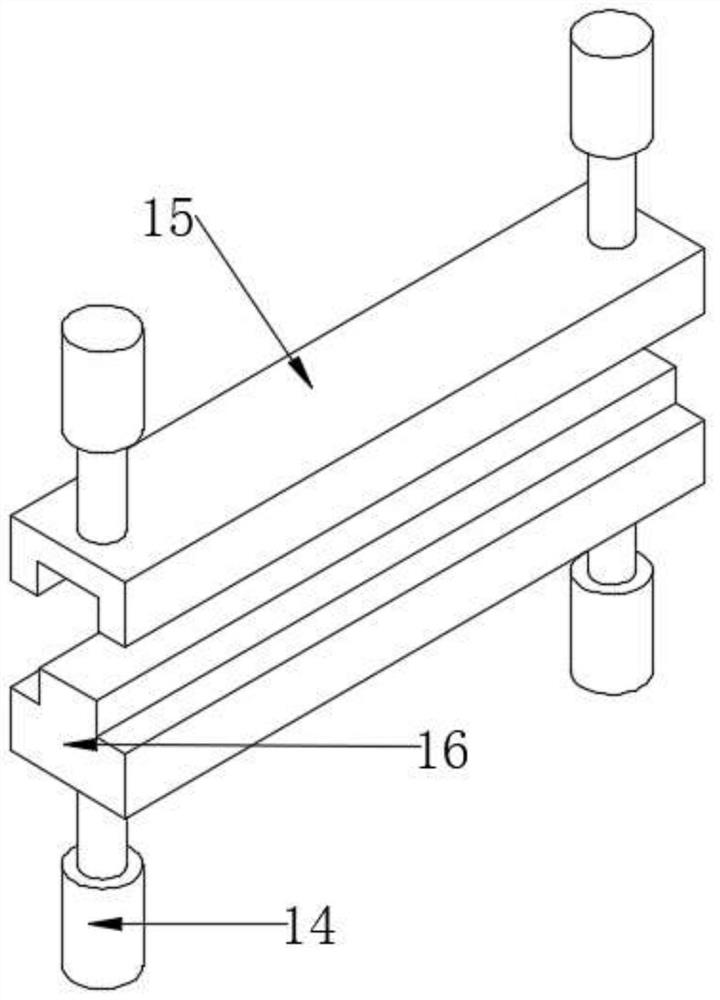

[0023] see Figure 1-4 , the present embodiment provides a fiber dyeing device for weaving, which includes an outer casing 17, and two ends of the outer casing 17 are provided with horizontal "I"-shaped gaps as inlet and outlet ports. Both ends of the outer casing 17 are provided with guide wheels 10, and are also provided with a traction mechanism. The traction mechanism includes an upper clamping part 15, a lower clamping part 16 and a driving structure. There is a groove, the lower clamping part 16 is provided with a protrusion corresponding to the shape of the groove, the driving structure includes a driving motor 1, a threaded collar 5 and a driving screw 6, and the outer casing 17 is fixedly arranged There is a supporting frame 2 for supporting, the driving motor 1 is fixedly arranged on the supporting frame 2 and connected to the driving screw 6 by driving, the threaded collar 5 is threaded on the driving screw 6 and its Between the upper clamping part 15 and the lower...

Embodiment 2

[0032]On the basis of Embodiment 1, a stirring mechanism is also provided, and the stirring mechanism includes a stirring motor 18, a transmission shaft 20 and a stirring rod 21, and the stirring motor 18 is fixedly arranged and its driving connection side is provided with some stirring rods 21 The transmission shaft 20 stirs the paint in the paint bin 19 by being provided with a stirring mechanism, so that the paint in the paint is always in a uniformly mixed state to prevent sedimentation; a purification box 26 is arranged below the drying chamber, and the The purification box 26 is provided with a wind-inducing component 24 and an air-dispersing disk 25, and the air containing a large amount of pigment odor is purified by the purification box 26, thereby reducing the harm to the environment. The purification method in the purification box 26 can be selected Existing chemical purification, or activated carbon adsorption.

Embodiment 3

[0034] On the basis of Embodiment 1, the upper clamping part 15 and the lower clamping part 16 are wave-shaped to enhance the stability of clamping the filamentary fiber raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com