Transverse conveying mechanism for automatic film covering machine

A technology of horizontal conveying and laminating machine, which is applied to the general parts of printing machinery, printing machines, printing, etc. It can solve the problems of low degree of automation and the overall length of equipment affecting space utilization, so as to improve production efficiency and space utilization rate, improve the effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

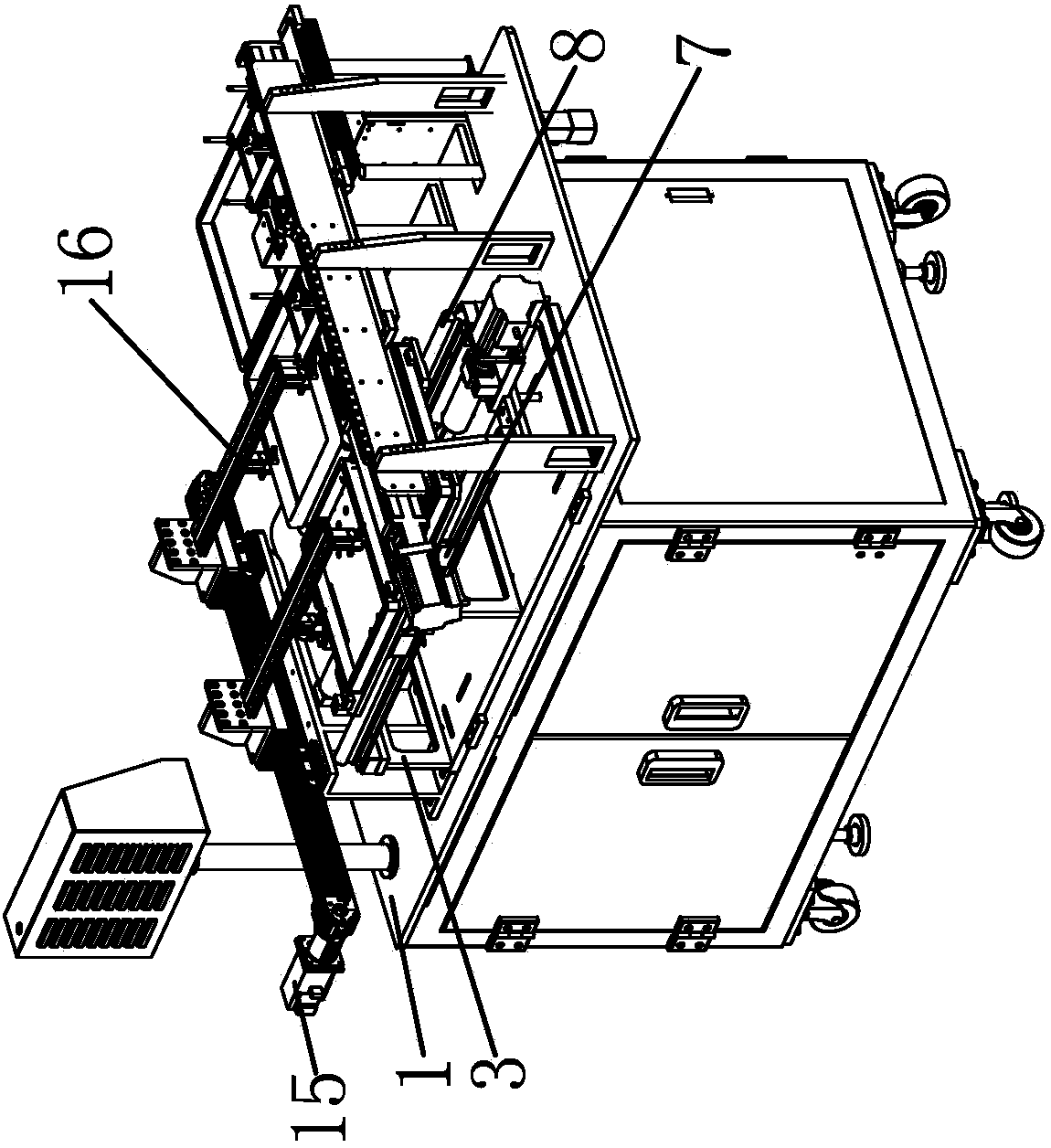

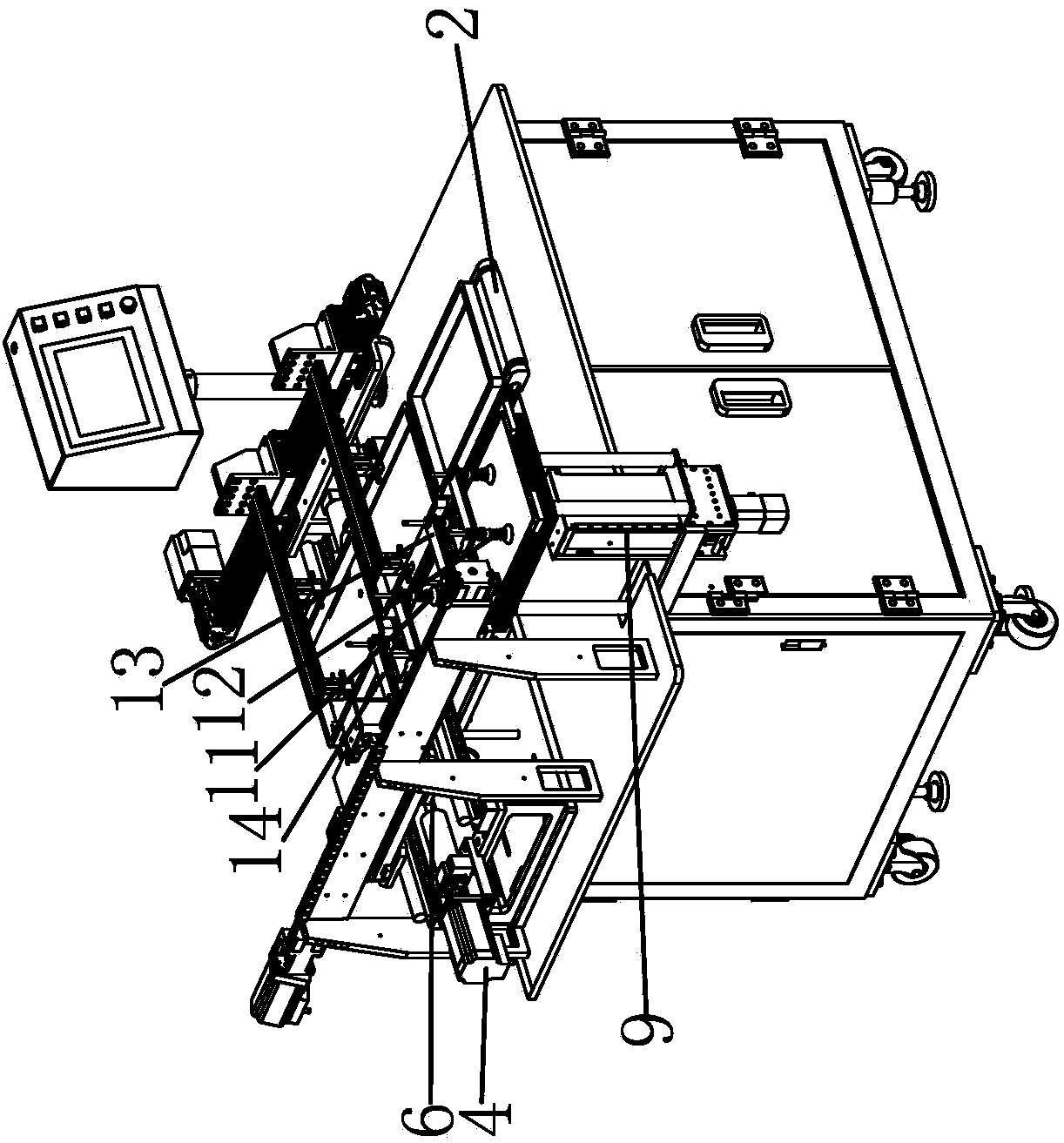

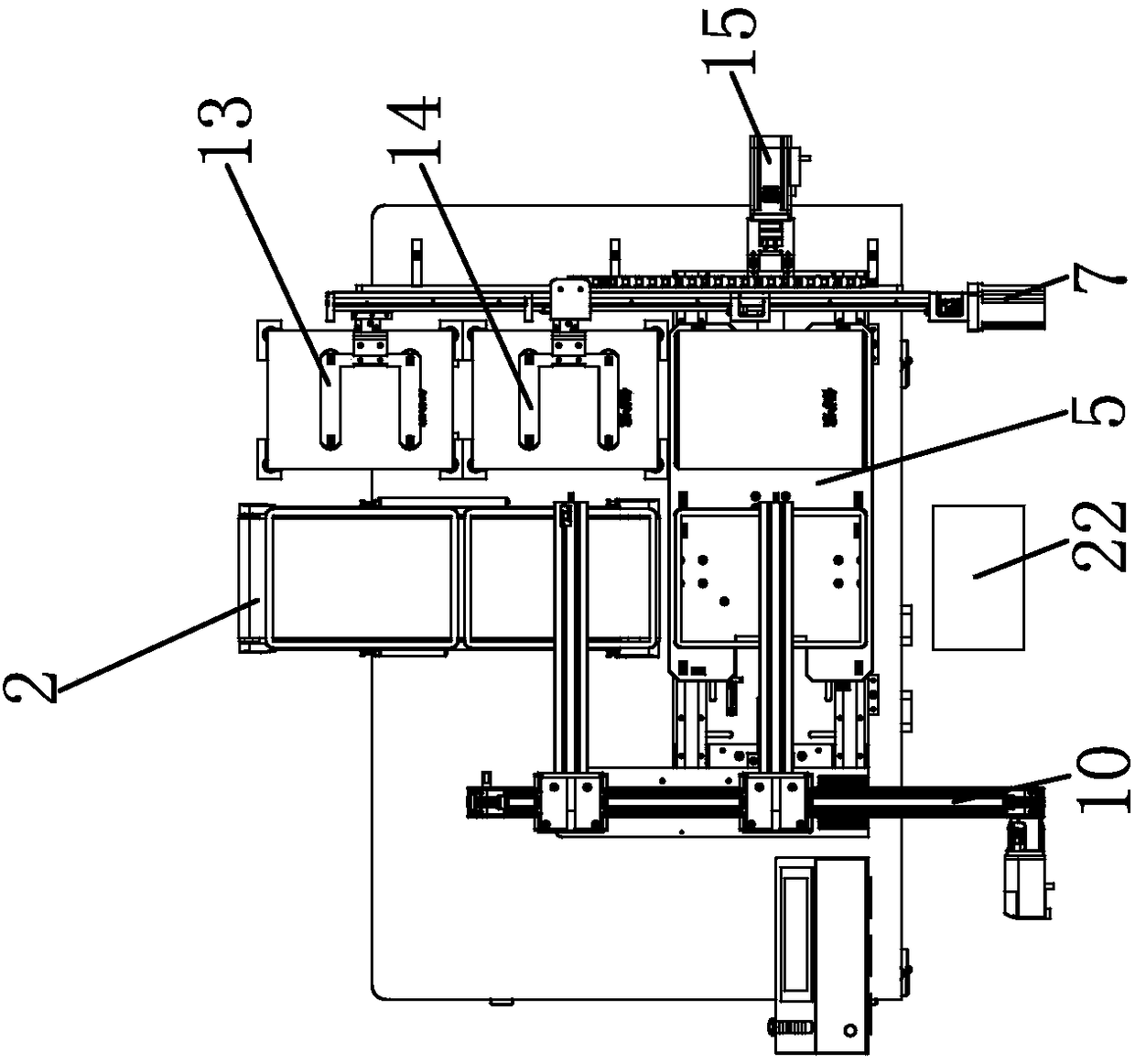

[0030] Such as Figure 1-5 As shown, an automatic laminating machine includes a workbench 1, a conveyor belt 2 is provided on the workbench 1, the conveyor belt 2 has a feeding end and a feeding end, and the conveyor belt 2 is set between two rotating shafts. One of the rotating shafts is connected with a motor that can make it rotate, and the body of the motor is fixed on the workbench 1. Drive the conveyor belt 2 to rotate through the motor one, so as to realize the forward conveying of the uncoated articles, and a transverse conveying mechanism that can drive the articles to move laterally is provided near the feeding end. The transverse conveying mechanism includes a working frame 3, a motor 2 4, Conveyor platform 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com