Automatic overturning mechanism and automatic overturning device

An automatic flipping and flipping bar technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as error-prone, low efficiency of manual flipping, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

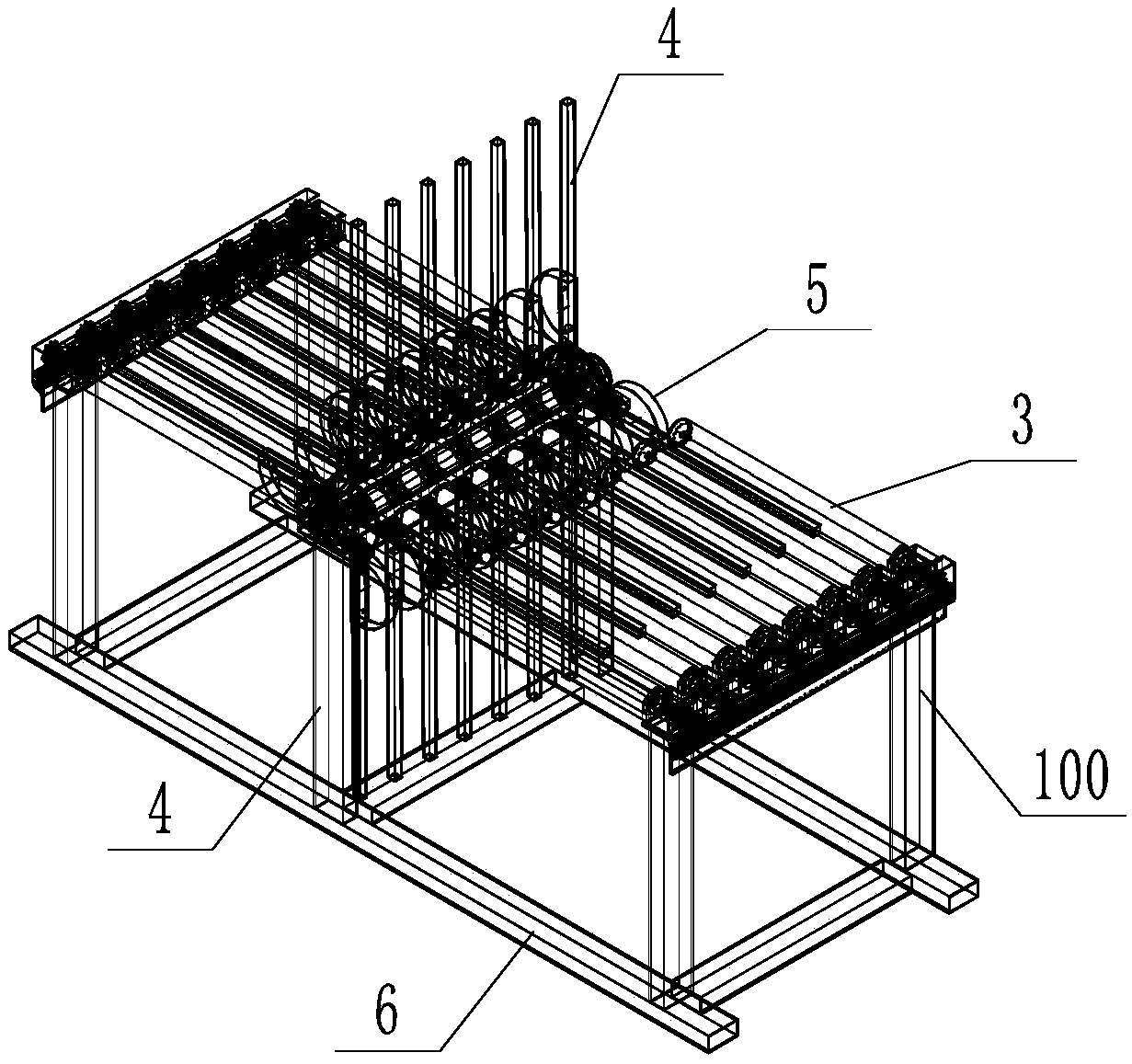

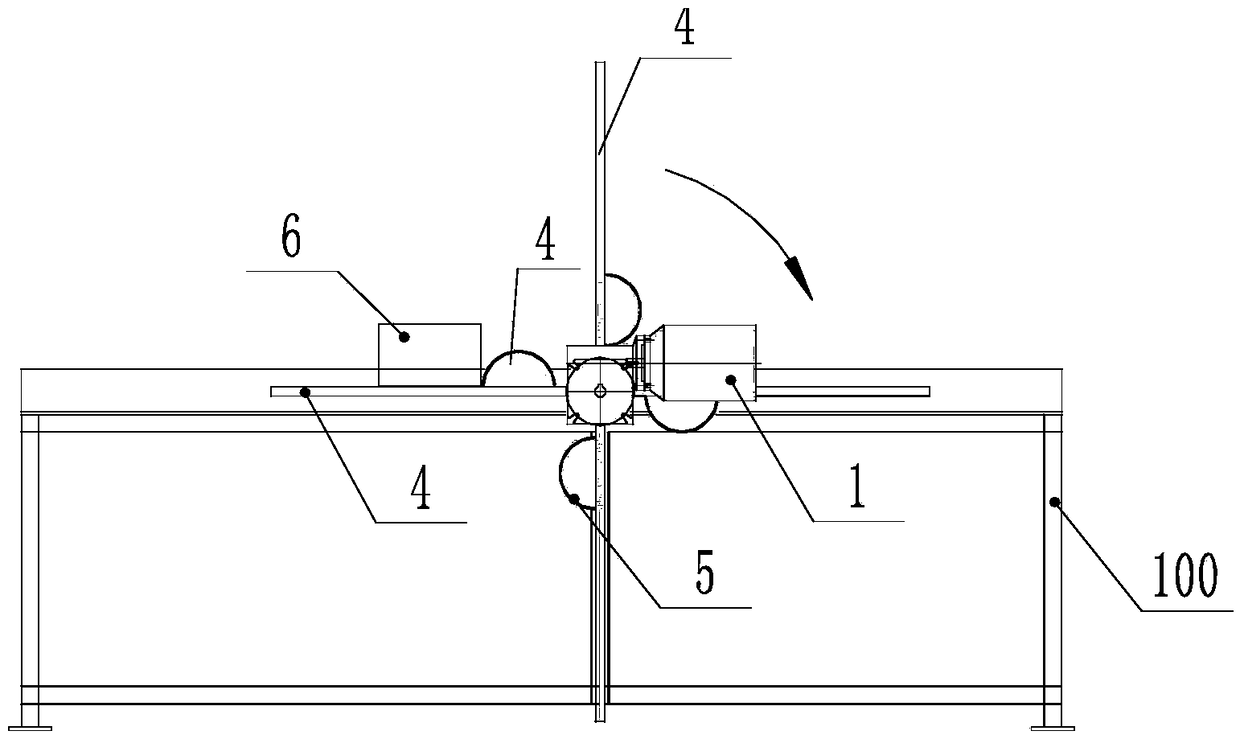

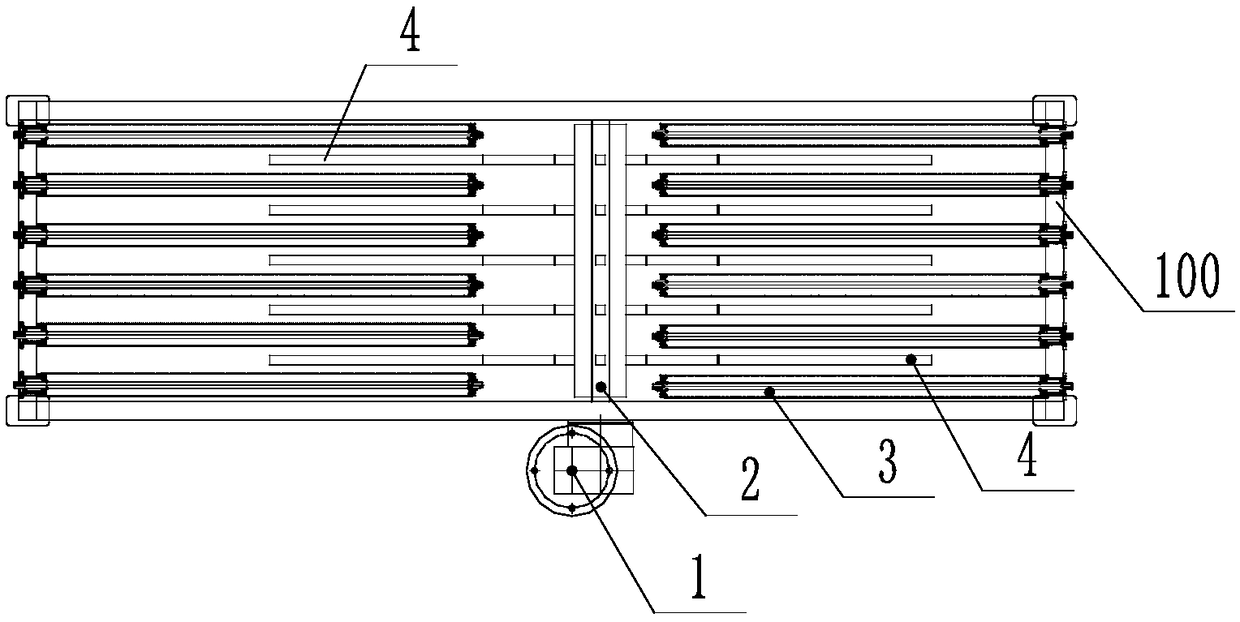

[0029] An automatic turning mechanism, comprising a driving motor 1, a rotating shaft 2, a turning lever 4 and a limit ring 5, the driving motor 1 is a stepping motor, the rotating shaft 2 is in transmission connection with the driving motor 1, and the turning lever 4. There are several groups, and each group of turning rods 4 is fixedly connected to the rotating shaft 2, and each group of turning rods 4 is distributed on the outer periphery of the rotating shaft 2 in a cross shape with the rotating shaft 2 as the center of symmetry; in this embodiment, each group There are four overturning levers 4, each overturning lever 4 is perpendicular to the axis of the rotating shaft 2, and two adjacent overturning levers 4 are perpendicular to each other. In order to treat the flipped items 6 to realize the limit during the flipping process, such as figure 1 and 2 As shown, a limiting ring 5 is provided on each turning lever 4, and the limiting ring 5 is fixedly connected with the tu...

Embodiment 2

[0031] An automatic turning device, comprising the automatic turning mechanism in Embodiment 1, also includes a frame 100, a transmission structure and a buffer device, in the present embodiment, the transmission structure is a transmission roller 3, and the buffer device is an elastic strip ( not marked). The stepper motor is fixedly installed on the frame 100 . There are several driving rollers 3, and each driving roller 3 is rotatable relative to the frame 100, and the driving rollers 3 are symmetrically arranged in two rows on the cargo conveying line. To realize the turning over of the article 6 is to turn the article 6 over 180° from one row of drive rollers 3 to the other row of drive rollers 3 . The elastic strip is fixedly arranged on the outer surface of the transmission roller 3, so that the article 6 can fall on another row of transmission rollers 3 stably, reducing the impact force. In other embodiments, the buffer device can also be an elastic member directly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com