A power plant energy-saving ash conveying system and method

An ash conveying and power plant technology, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of waste of resources, large demand for compressed air, irregular time, etc., to save resources and facilitate the control of the operating state of the unit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

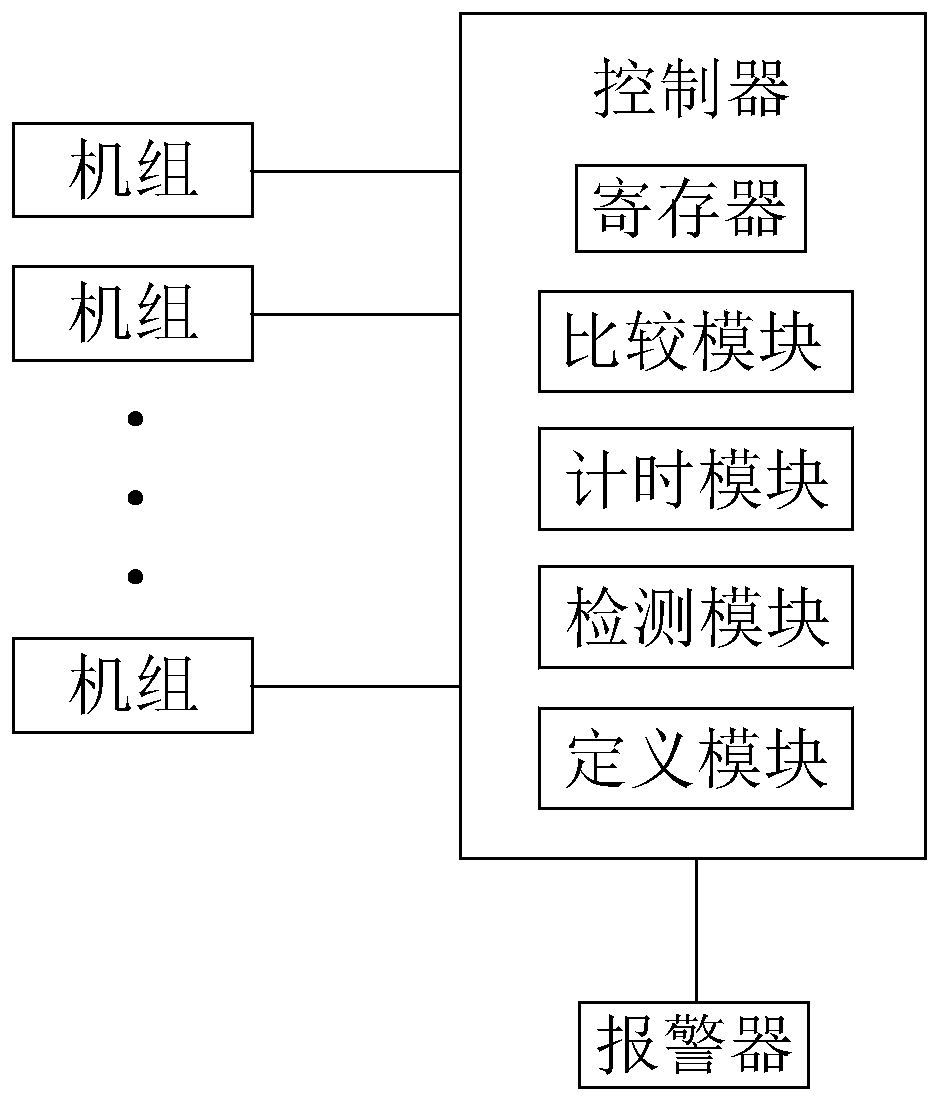

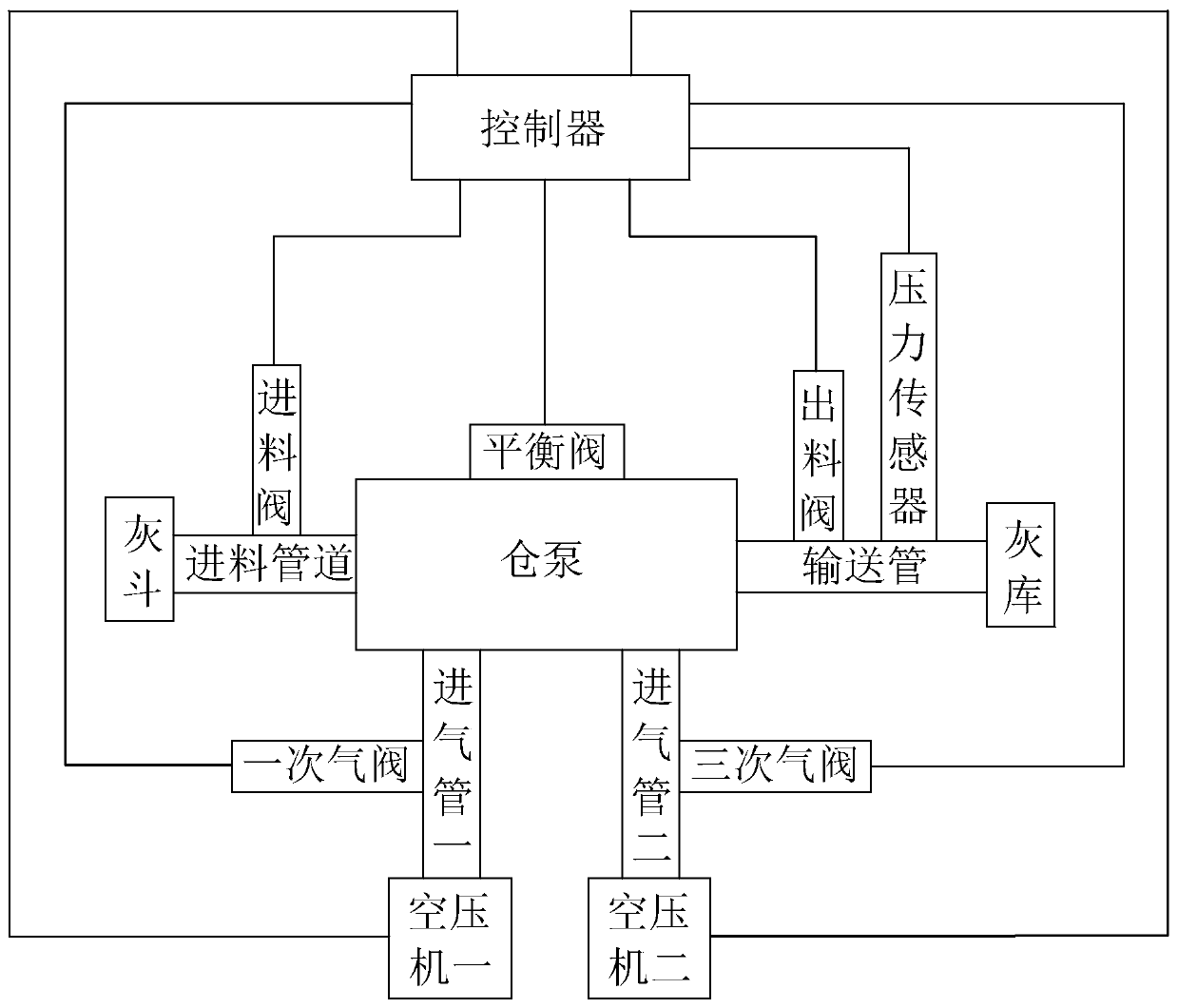

[0046] An energy-saving ash conveying system for a power plant, referring to figure 1 , The power plant includes an ash storehouse and multiple ash hoppers, the ash hoppers correspond to the dust collectors of the power plant, and the ash storeroom is used to store dry ash. The energy-saving ash conveying system includes a controller and multiple units, and the controller is PLC. Each unit is correspondingly connected to each ash hopper for transporting dry ash to the ash storage. The controller is connected with each unit for controlling the operation of each unit. When the number of units that are conveying ash is not less than the set number, the controller will control other units to suspend work and queue up sequentially. When the number of running units is less than the set number, the controller will control the units at the front of the queue to convey ash.

[0047] refer to figure 1 , the controller includes a register and a comparison module, the number of runnin...

Embodiment 2

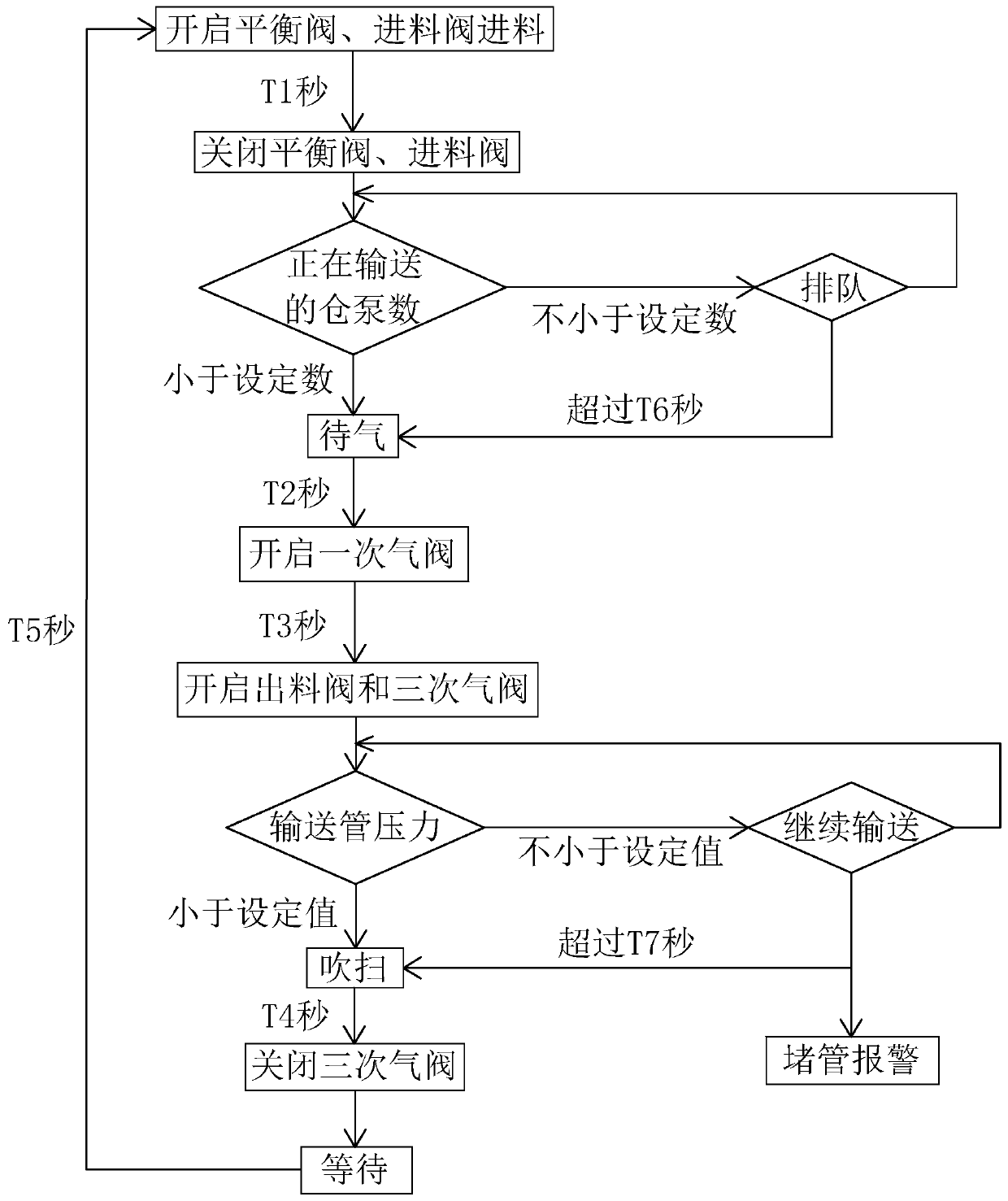

[0053] A kind of power plant energy-saving ash conveying method based on the power plant energy-saving ash conveying system in embodiment 1, refer to figure 2 and image 3 , every time the warehouse pump transports a group of dry ash is a working cycle, and each working cycle includes the following stages:

[0054] In the feeding stage, the controller controls the opening of the balance valve and the feed valve, and the dry ash in the corresponding ash hopper falls freely into the bin pump under the action of gravity; when the opening time of the balance valve and the feed valve reaches the preset opening time T1 , the controller controls the balance valve and the feeding valve to close, the feeding stage ends and enters the queuing stage;

[0055] In the queuing stage, the number of bin pumps that are transporting dry ash is judged. When the register (refer to figure 1 ) recorded in the number of bin pumps that are transporting dry ash is not less than the comparison modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com