Sliding supporting seat utilizing hydraulic hammer guide grooves to guide displacement

A technology of hydraulic hammer and support seat, which is applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of complicated and time-consuming process, large manpower labor, etc., achieve the effect of simple structure, convenient use, and avoid frequent disassembly of hydraulic hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

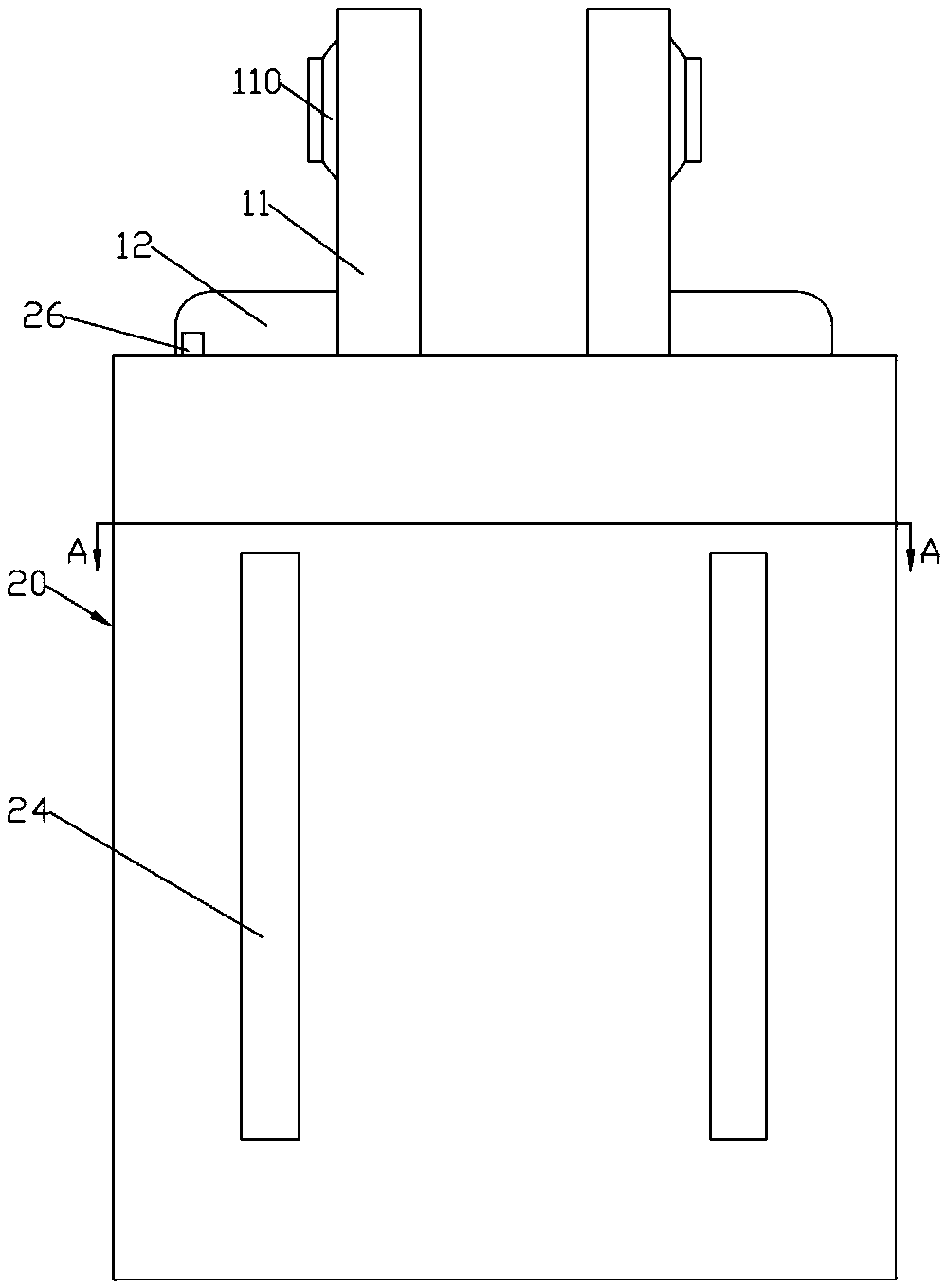

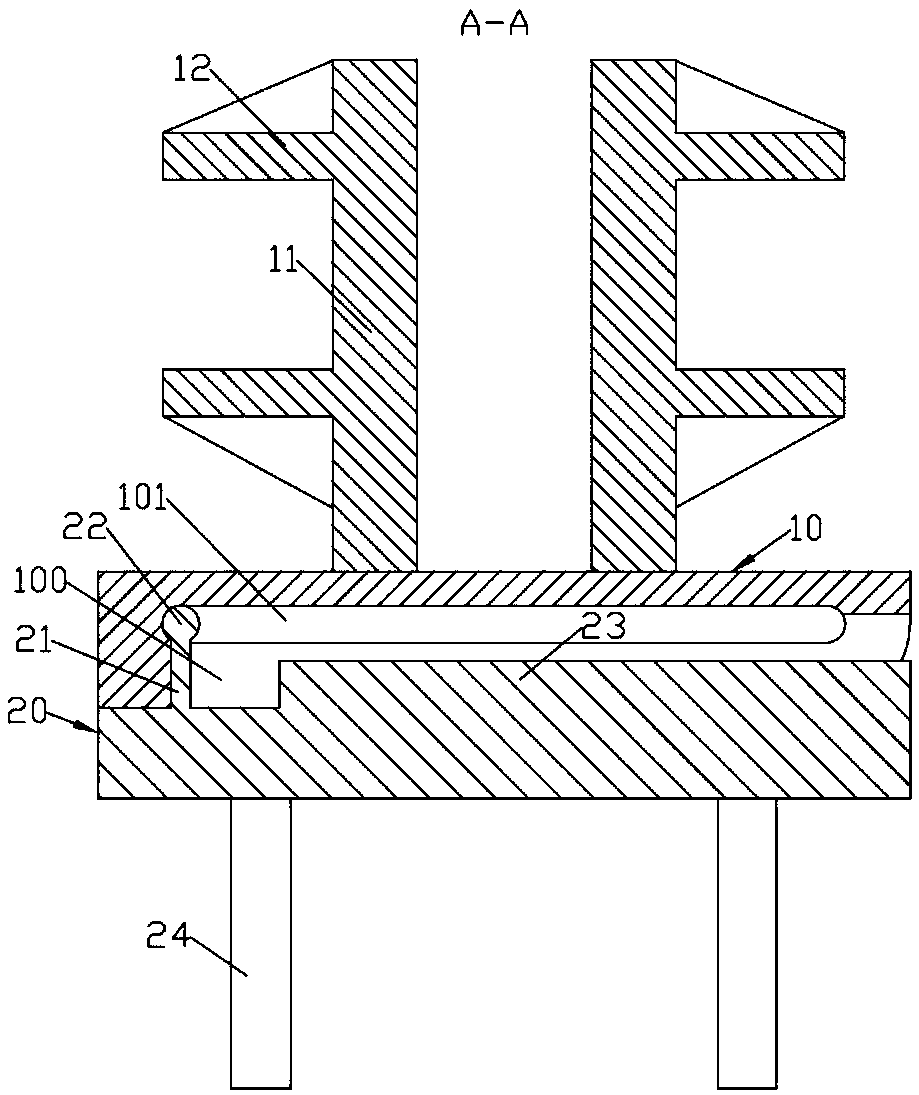

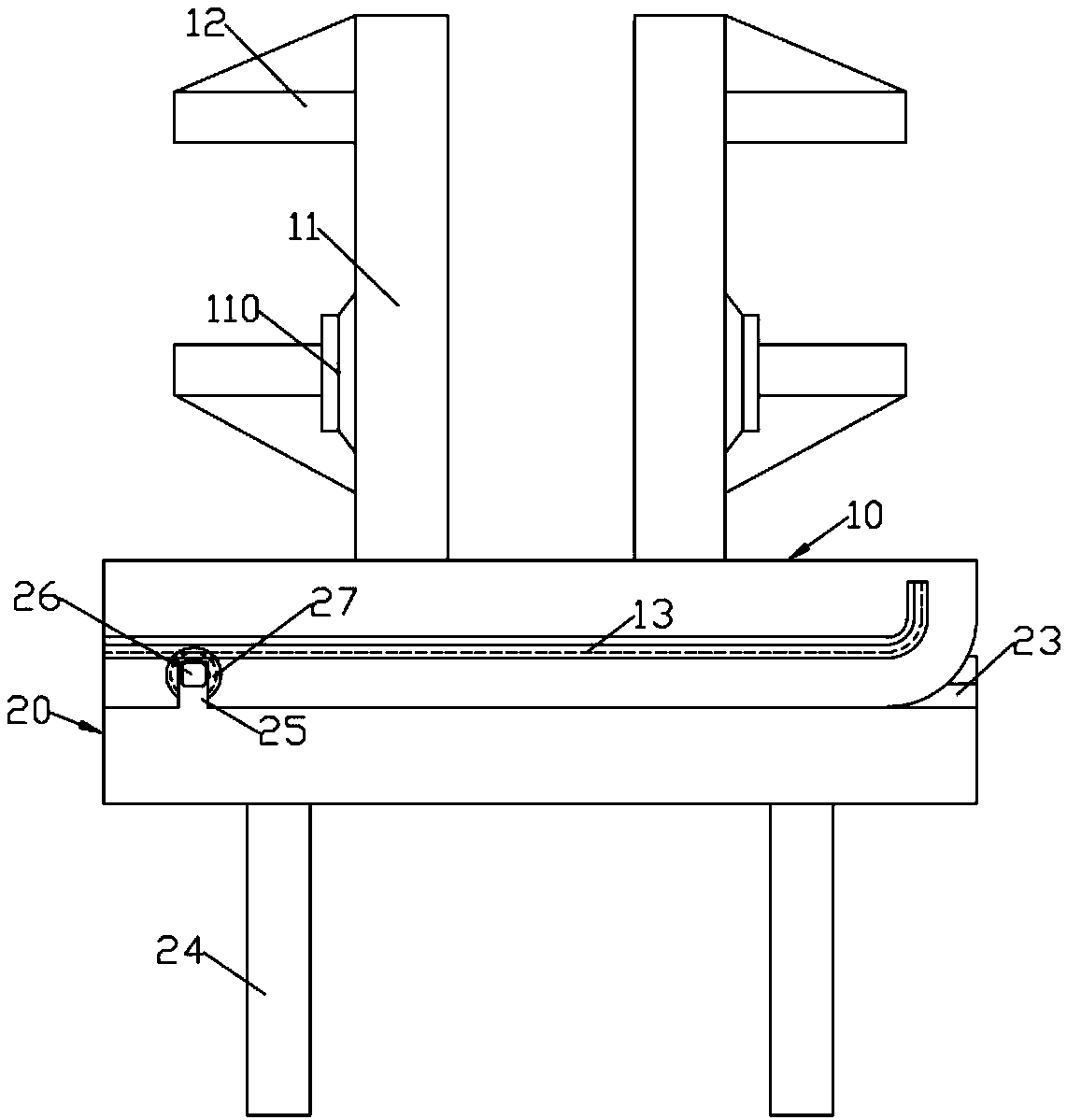

[0017] Such as Figure 1 to Figure 6 As shown in the figure, a sliding support seat guided by a hydraulic hammer guide groove includes a rectangular main support plate 10 and a secondary support plate 20; a pair of left and right symmetrical sliding plates 11 are vertically welded on the rear end surface of the main support plate 10; The inside of the support plate 10 is formed with a number of long hole-shaped sliding grooves 101 distributed up and down; the front part of the sliding groove 101 and the middle part of the side wall of the right part are provided with guide grooves 100; A number of guide blocks 21 distributed up and down that cooperate with the guide groove 100; the rear end of the guide block 21 is formed with a cylindrical sliding column 22 and the upper and lower ends of the sliding column 22 respectively exceed the upper and lower end surfaces of the guide block 21; the guide block 21 slides to set In the guide groove 100; the sliding column 22 slides and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com