Alignment and mounting method for reamer suction dredger cutter shafting

A cutter-suction dredger and its installation method are applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., and can solve the problems that cannot meet the construction requirements and strength of high-power cutter-suction dredgers. Poorly cracked, low contact stiffness and other problems, to achieve the effect of shortening the construction period, prolonging the whole life cycle, and high alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

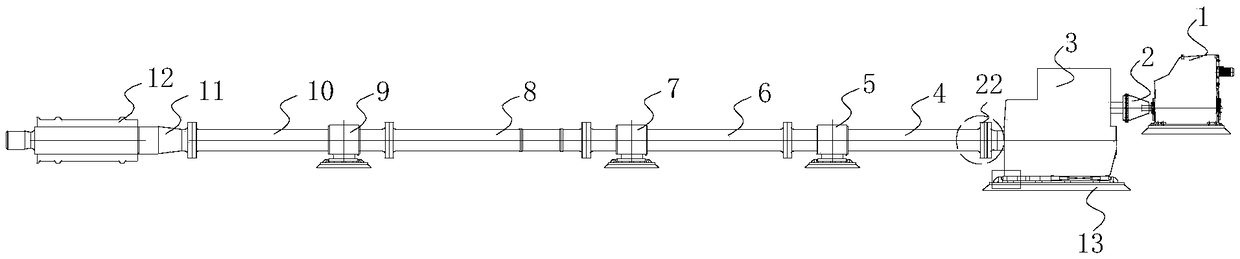

[0050] In this embodiment, the cutter shafting of a cutter suction dredger with a cutter power of 5000kw is taken as an example, as figure 1 As shown, in the direction from the bow to the stern, the reamer shaft system includes two driving motors 1, two clutches 2, a gearbox 3, 1# intermediate shaft 4, 1# intermediate bearing housing 5, and 2# intermediate shaft 6. 2# intermediate bearing seat 7, 3# intermediate shaft 8, 3# intermediate bearing seat 9, 4# intermediate shaft 10, reamer shaft 11 and reamer bearing seat 12; each drive motor 1 is connected with a clutch 2 connection; both clutches 2 are connected with the gearbox 3.

[0051] On the basis of the above-mentioned reamer shafting system, the present invention uses the following meth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap