Ultra-low concentration gas safety mixing device and method

An ultra-low concentration, gas technology, used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as difficulty in uniform mixing, uneven distribution of mixed gas calorific value, stratification, etc. good mix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

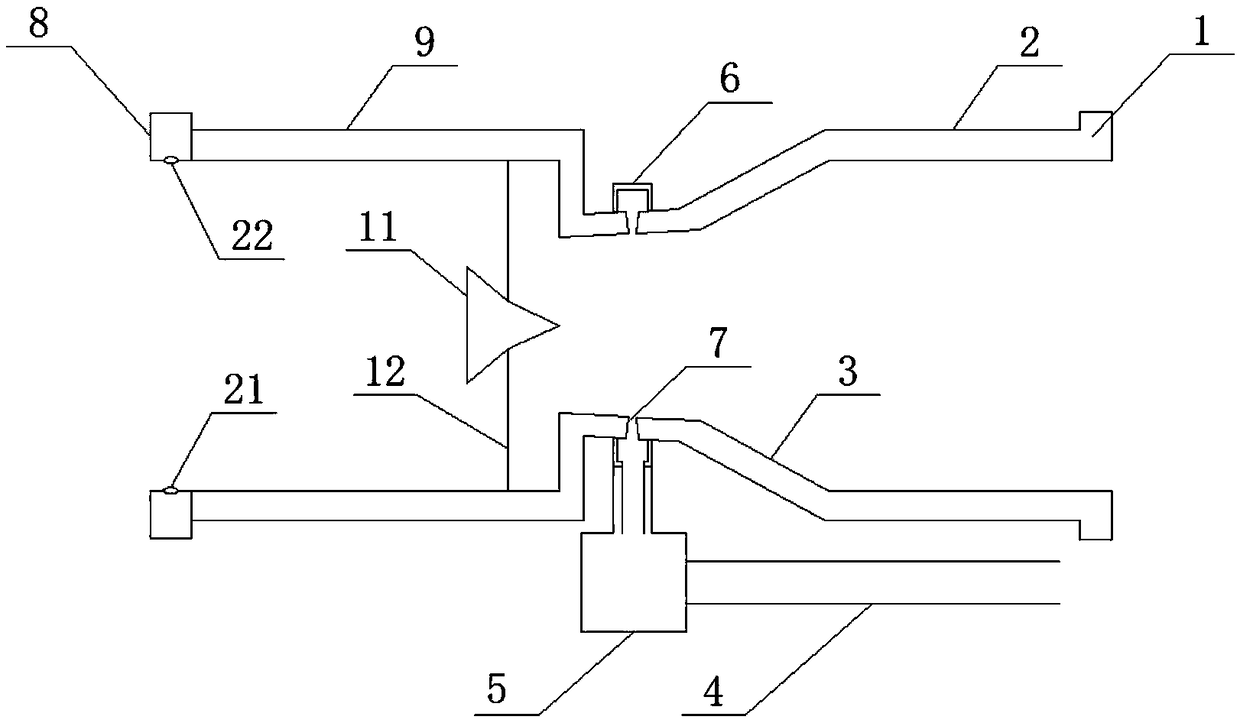

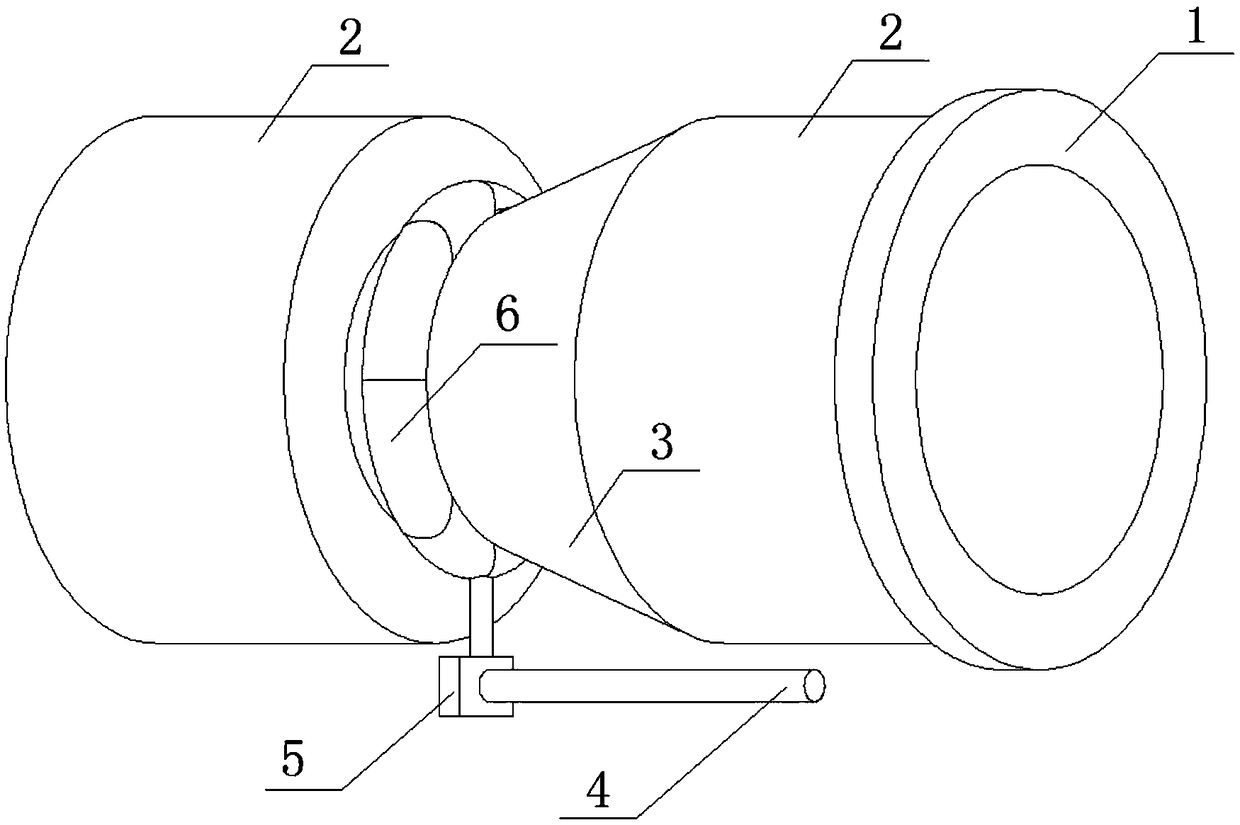

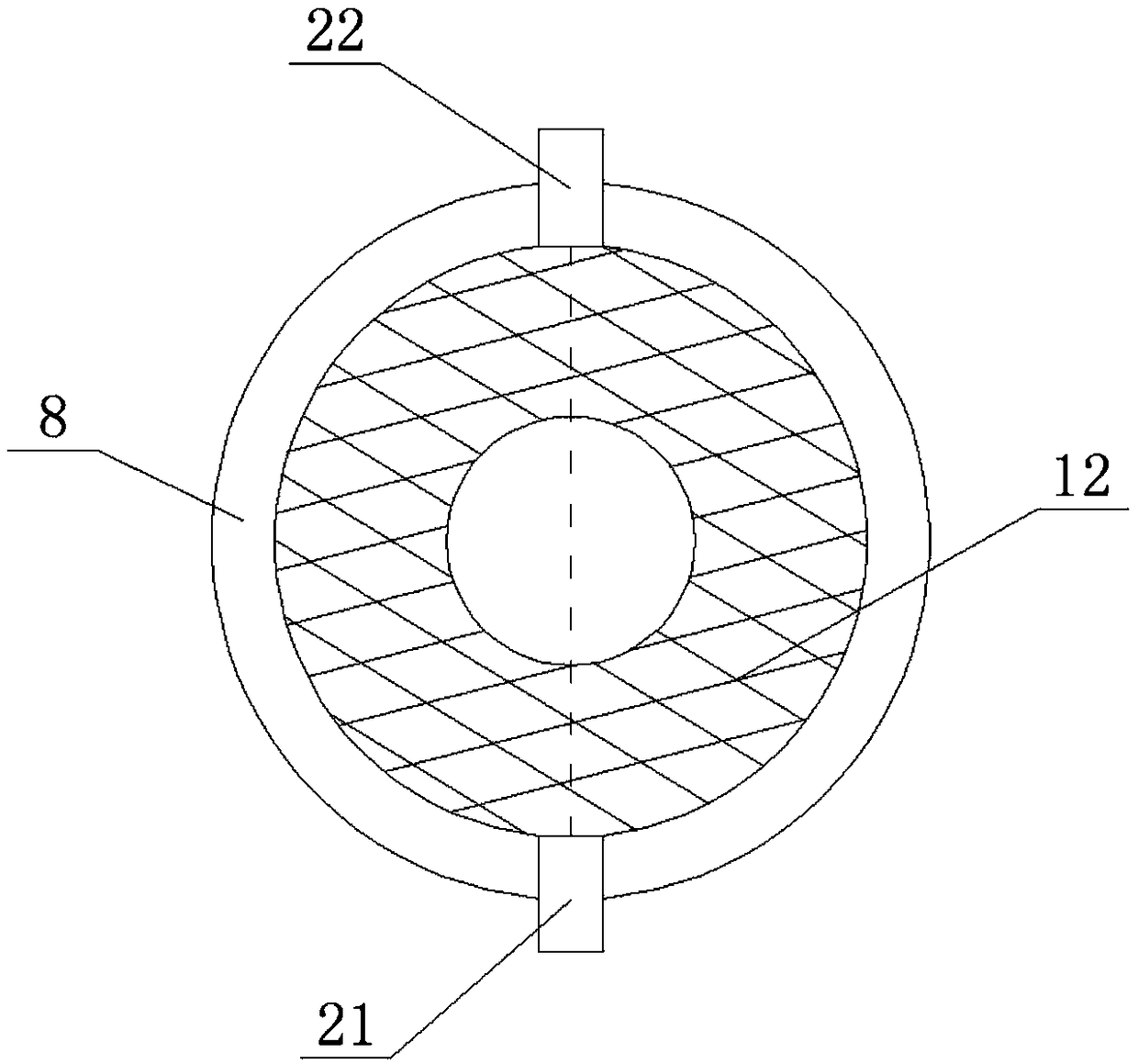

[0037] Such as Figure 1-3 As shown, an ultra-low concentration gas safety mixing device includes an inlet flange 1, an inlet pipe 2, a narrowing pipe 3, an outlet pipe 9, and an outlet flange 8 connected in sequence; the inlet pipe 2 and the outlet pipe 9 It is a conventional pipeline with equal diameters. The diameter of the narrowed pipeline 3 connected to the inlet pipeline 2 is the same as that of the inlet pipeline 2, and the diameter of the side connected to the outlet pipeline 9 is small, and the diameter of the junction of the narrowed pipeline 3 and the outlet pipeline 9 changes suddenly;

[0038] A ring-shaped pipe 6 is provided on the outer wall of the narrowed pipe 3, and a circle of gaps 7 connecting the inner chamber of the annular pipe 6 and the inner chamber of the narrowed pipe 3 is provided at the sealed joint of the annular pipe 6 and the narrowed pipe 3 ;

[0039] The inner cavity of the annular pipe 6 is connected to a high-concentration pipe 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com