Fully-automatic concentrating solar cooker

A solar cooker, fully automatic technology, applied in mobile/directional solar collectors, solar thermal energy, solar thermal collectors, etc., can solve problems such as high environmental and equipment requirements, high material requirements, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

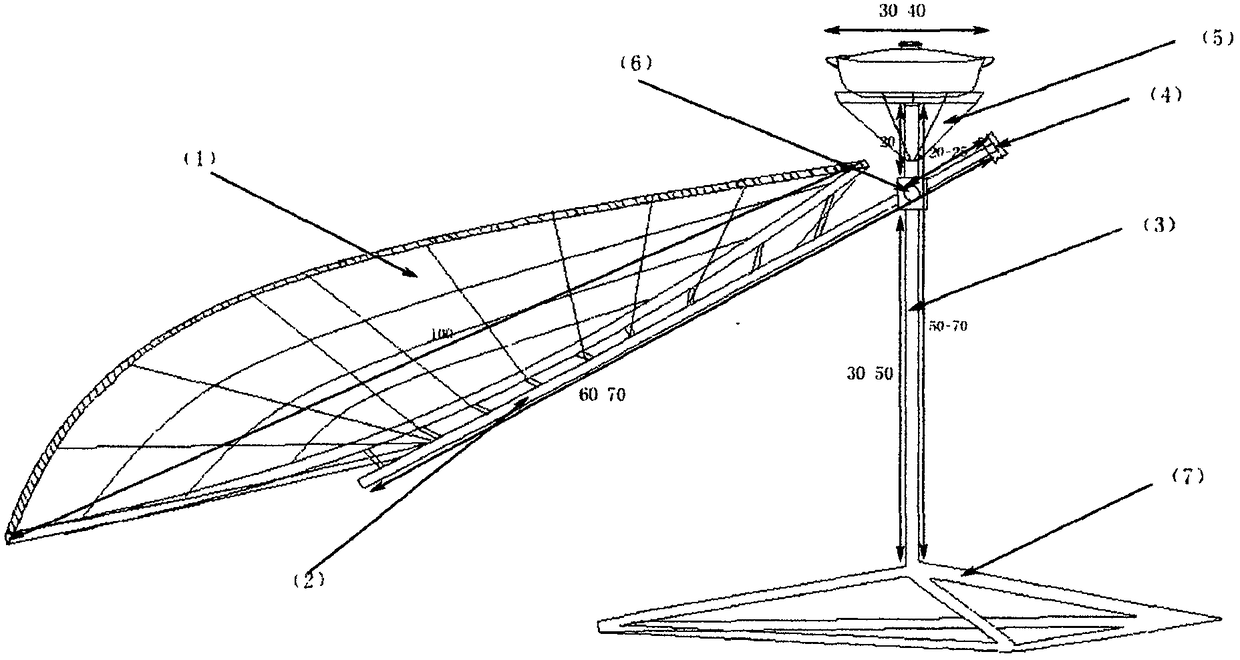

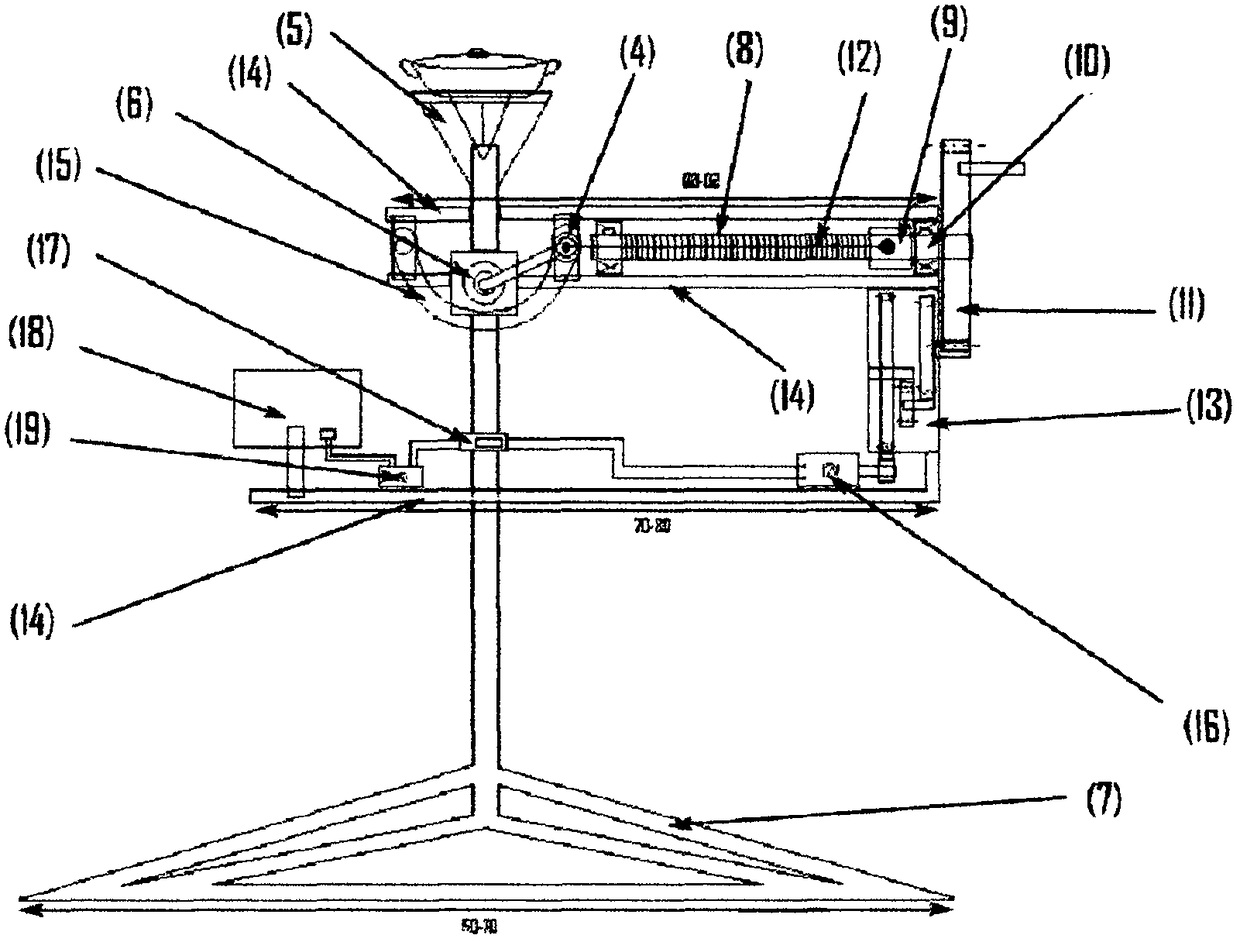

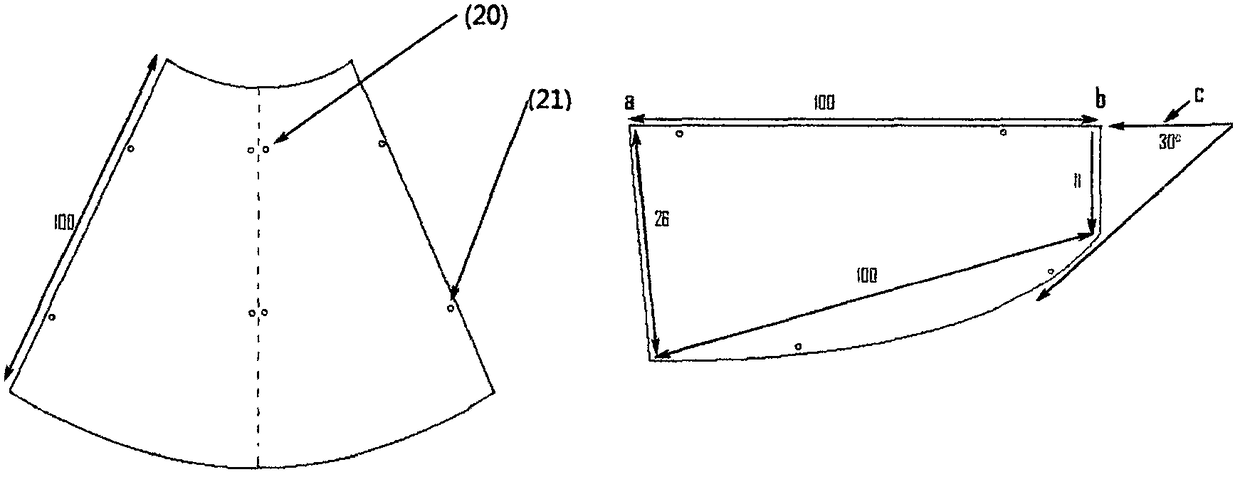

[0049] A fully automatic concentrating solar cooker of the present invention consists of a reflector (1), a reflector support rod (2), a main support column (3), a chute wheel (4), a heating fuse frame (5), a universal Bearing (6), base (7), transmission screw (8), transmission nut (9), screw bearing (10), hand wheel type large gear (11), transmission connecting rod (12), gearbox (13) , component support (14), chute (15), drive motor (16), cycle timer switch (17), solar panel (18), battery (19), chute seat cushion (20), wherein the main The support column (3) is connected with the base (7), the main support column (3) top is equipped with a heating fuse frame (5), the main support column (3) is equipped with a universal bearing (6), and the universal bearing ( 6) A reflector support rod (2) is installed on the reflector support rod (2), a reflector (1) is installed on the reflector support rod (2), a chute cushion (20) is installed on the support (14), and a chute cushion (20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com