Method for quantitatively characterizing contribution of flow field shearing to interface free energy of oil-water emulsification process

A technology of oil-water emulsification and quantitative characterization, which is applied in difficult areas and can solve problems such as unrealized quantitative characterization and inconvenient calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Below in conjunction with accompanying drawing, the present invention will be further described:

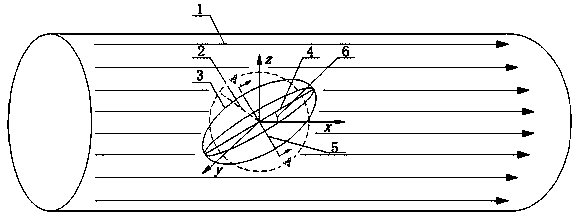

[0070] like figure 1 As shown, in the shear flow field 1 with a velocity gradient perpendicular to the flow direction of the oil-water medium, the original spherical oil-water emulsion droplet is deformed by the shear action of the flow field, and the radius 2 of the spherical droplet is deformed into an ellipse spherical droplet 3, and induce an orientation angle 6, and at the same time due to the axisymmetric nature of the deformation, the major axis 4 of the ellipsoid and the minor axis 5 of the ellipsoid have the same and are proportional to the deformation value of the radius 2 of the spherical droplet deformation value.

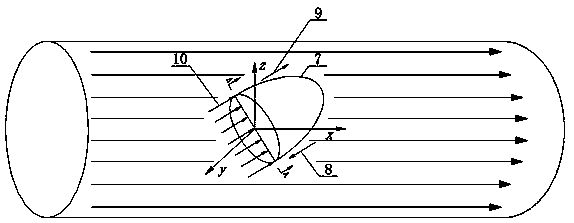

[0071] like figure 2 As shown, for the deformed ellipsoidal droplet 3, the semi-ellipsoidal droplet 7 is affected by the oil-water interfacial tension, the droplet shape restoring force 8 opposite to the deformation direction, and the viscous she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com