Detection device for load cable

A technology for pulling wire ropes and testing equipment, which is applied in the field of testing equipment, can solve problems such as wasting labor, affecting work efficiency, and slow inspection speed, and achieves the effects of improving inspection speed, reducing labor, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

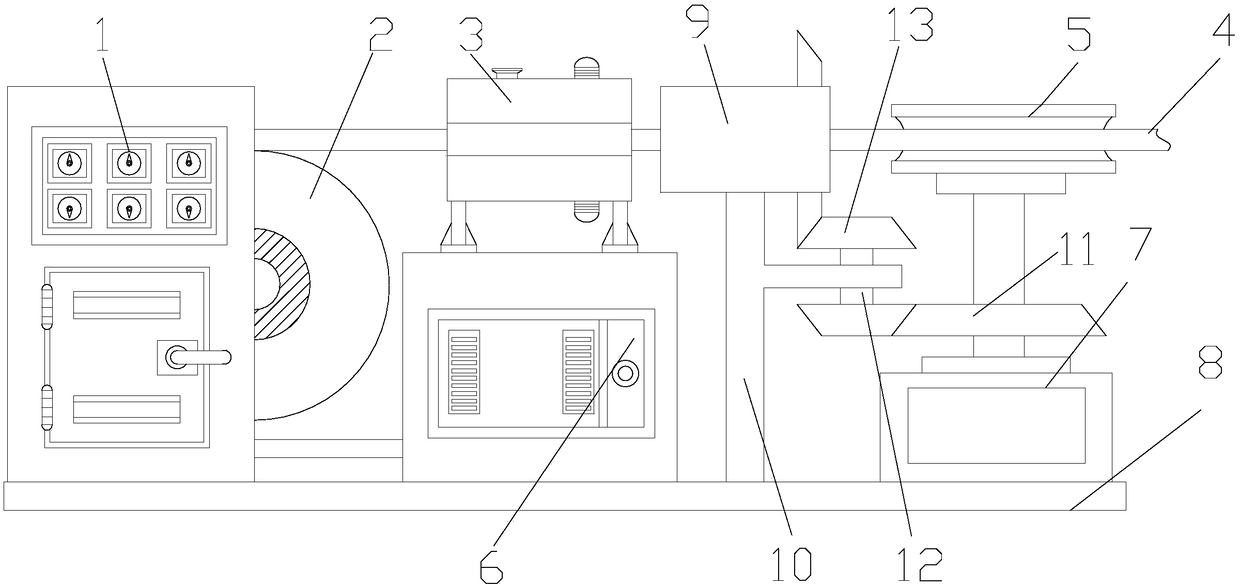

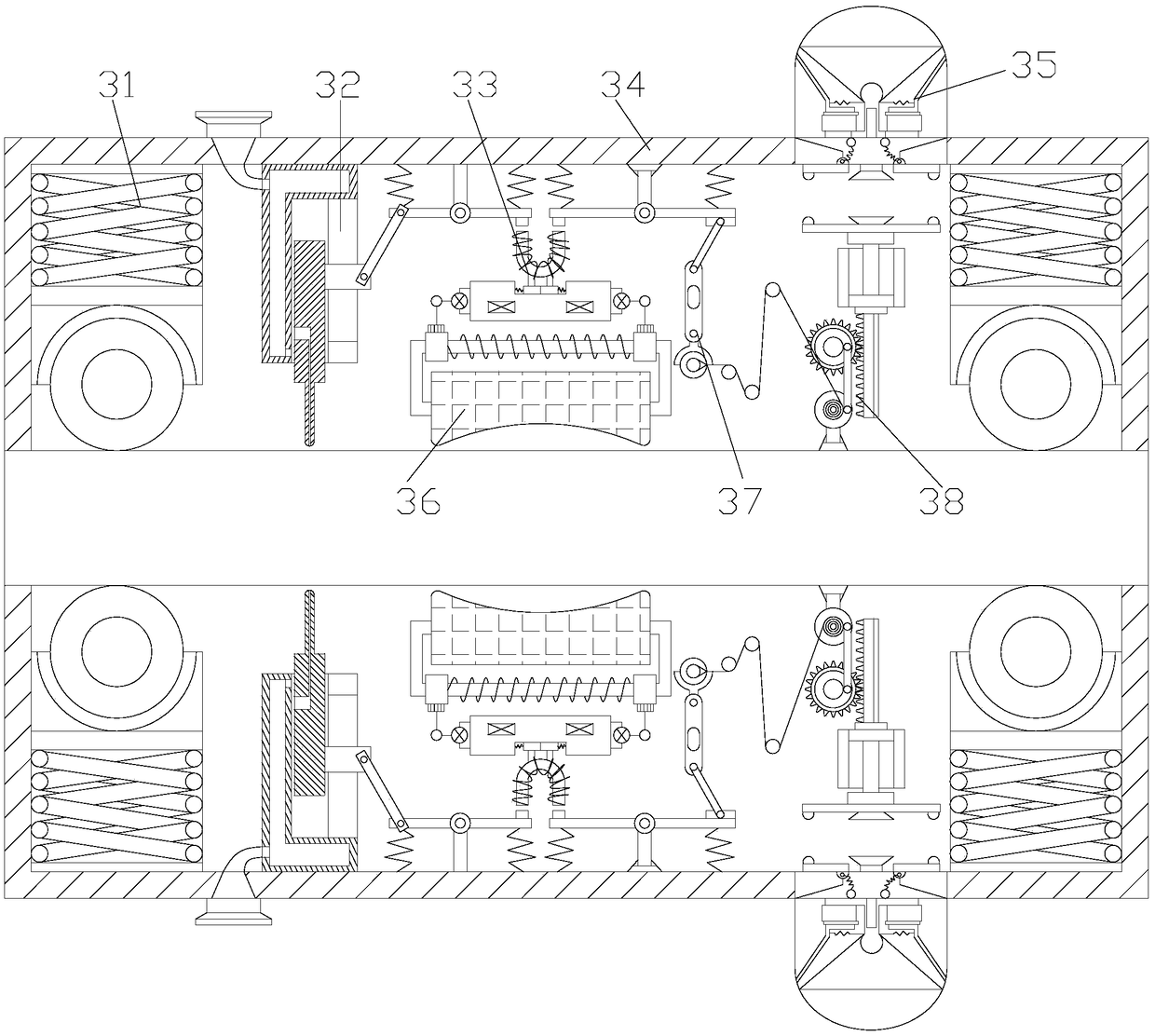

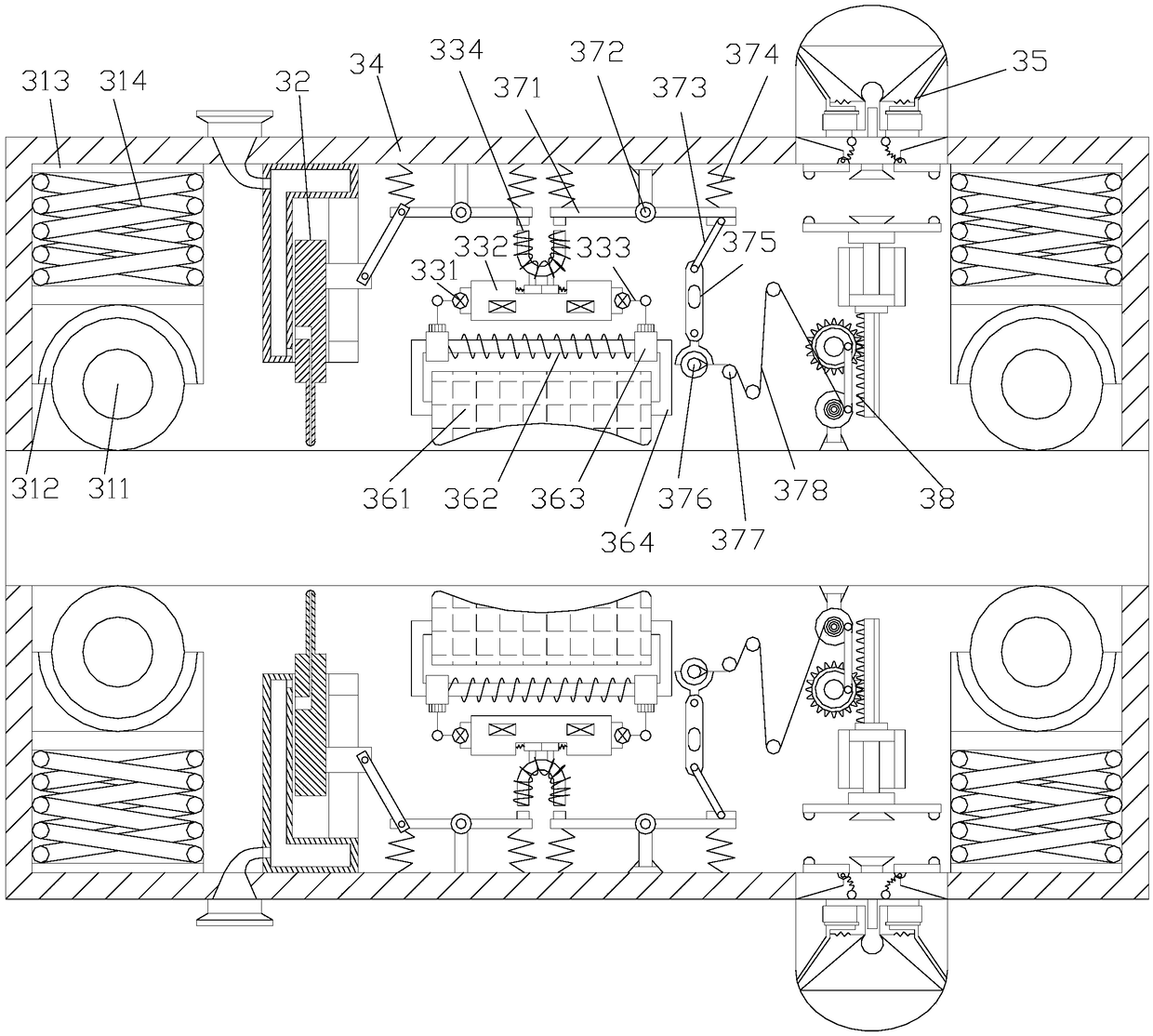

[0024] see Figure 1-Figure 6 , the present invention provides a detection device for traction steel wire rope, comprising a large rotating drum 2, a steel wire rope non-destructive testing device 3, a steel wire rope 4 and a power motor 7, the large rotating drum 2 is installed inside the machine body 1, and the steel wire rope non-destructive testing device 3 is welded to the top of the control cabinet 6, the top of the output shaft of the power motor 7 is keyed to the runner 5, the middle position of the output shaft of the power motor 7 is keyed to the main bevel gear 11, and the power motor 7 is connected to the base plate 8 Fixedly connected, between the power motor 7 and the control cabinet 6, a pillar 10 fixedly connected with the base plate 8 is provided, the top of the pillar 10 is fixedly connected with the cleaning mechanism 9, and the sub-pillars of the pillar 10 are connected with the rotating shaft 12 through bearings. The upper and lower ends of the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com