Intelligent garment making method and system

An intelligent and subsystem technology, applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as waste of manpower and time, inability to intelligently match order information to the hanging system, and inability to trace products, so as to reduce production capacity. The effect of improving delivery time, improving delivery accuracy, and eliminating related errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

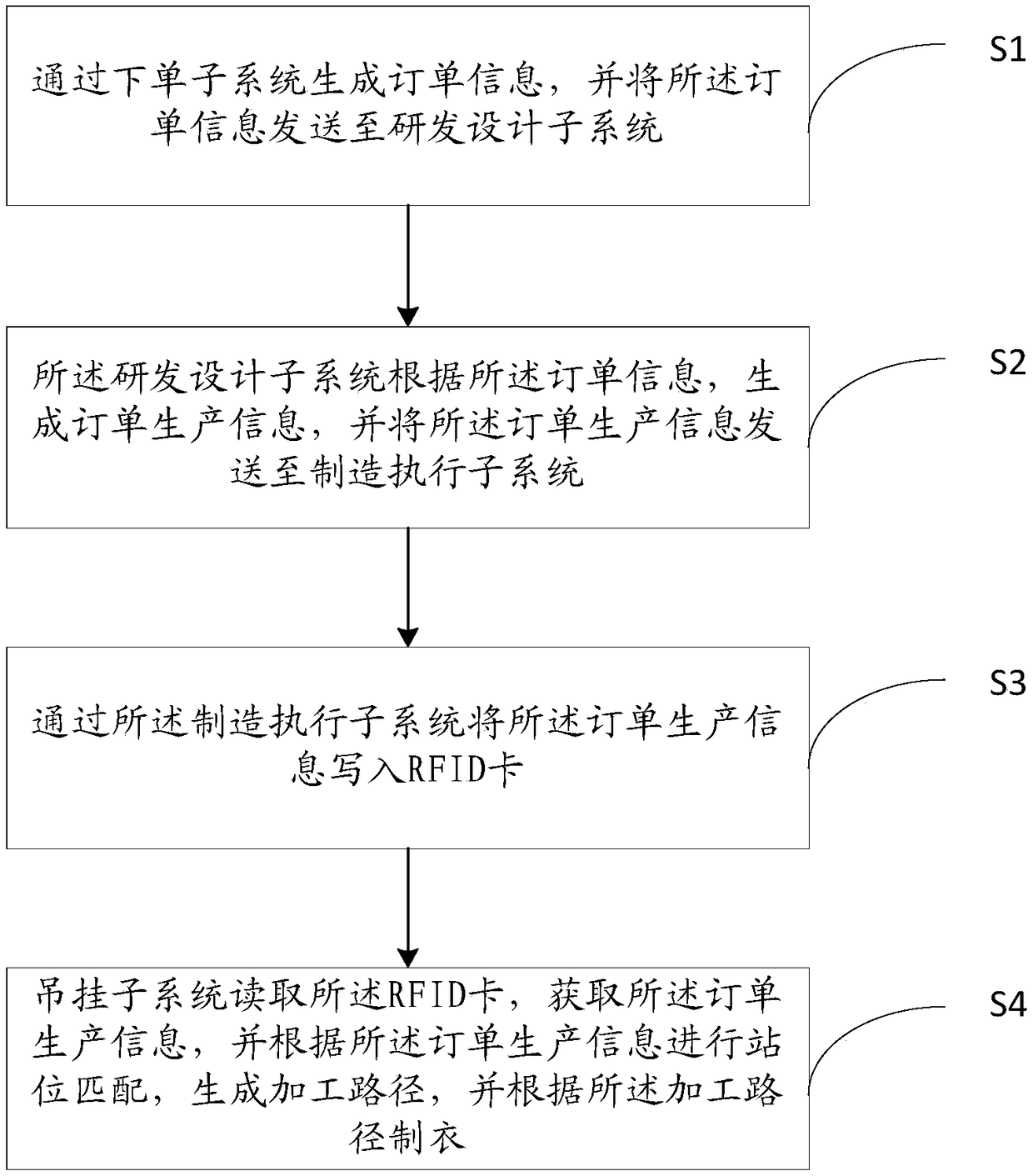

[0033] see figure 1 , is a flow chart of the smart clothing-making method provided in this embodiment. This intelligent clothing method comprises the steps:

[0034] S1: Generate order information through the order placing subsystem, and send the order information to the research and development design subsystem.

[0035] This step is used to generate an order. The customer places an order through the order placing subsystem, and the customer chooses fabrics, fabric colors, accessories and functional fabrics individually in the order placing subsystem.

[0036] Step S01 is further included after step S1: reviewing the order information through the first review module, and sending the reviewed order information to the R&D design subsystem.

[0037] In step S01, the first review module includes a production order management unit, an order material management unit, a pattern-making design unit, and an order material combination query unit.

[0038] The production order manage...

Embodiment 2

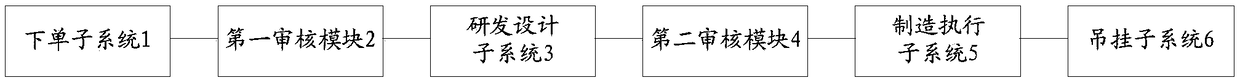

[0068] see figure 2 , is a structural block diagram of an intelligent clothing system provided in this embodiment. The intelligent garment system includes an order placing subsystem 1, a first review module 2, a research and development design subsystem 3, a second review module 4, a manufacturing execution subsystem 5 and a hanging subsystem 6;

[0069] The order placing subsystem 1 is used to generate order information; the first review module 2 is used to review the order information, and sends the reviewed order information to the research and development design subsystem 3; the research and development design subsystem 3, It is used to generate order production information according to the order information; the second review module 44 is used to review the order production information, and send the reviewed order production information to the manufacturing execution subsystem 5; manufacturing execution The subsystem 5 is used to write the order production information i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com