An armature cutting device

A cutting head and equipment technology, applied in the field of armature head cutting equipment, can solve the problems of difficult cutting, incomplete cutting, long processing time, etc., and achieve the effects of small radial force, flat cutting head, and fast clamping speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

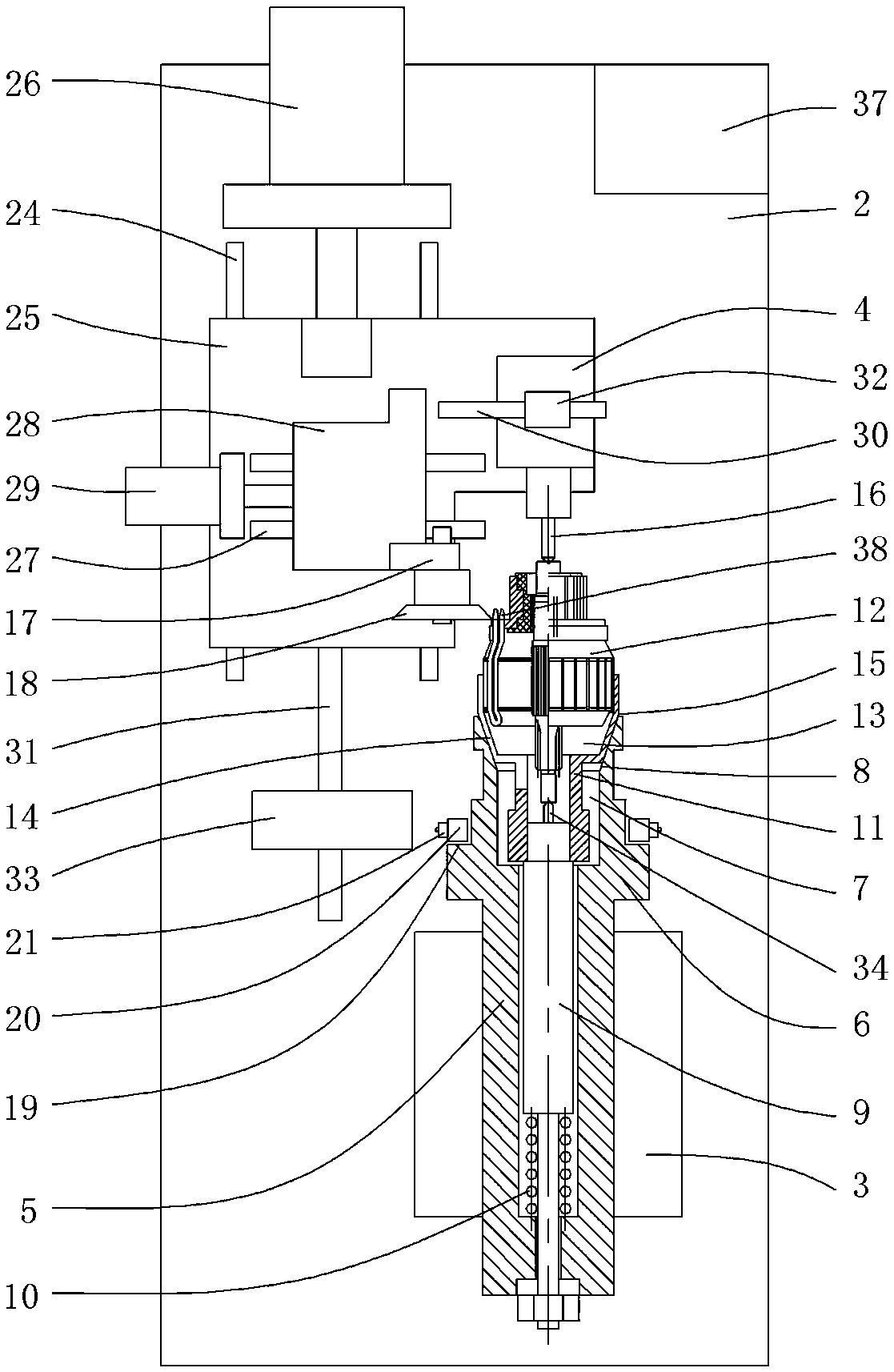

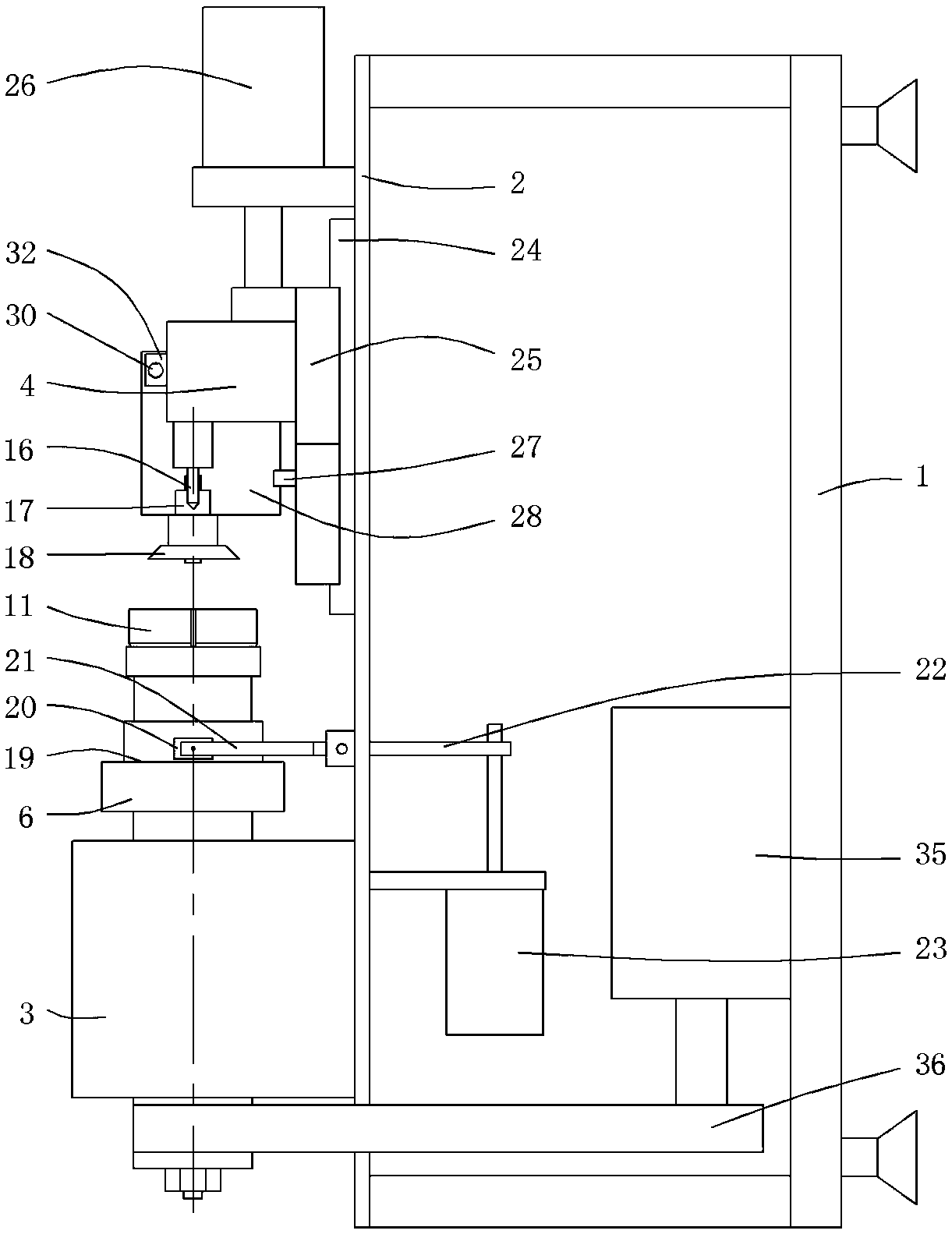

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] refer to figure 1 , figure 2 , an armature head cutting device, comprising a frame 1, a workbench 2 arranged on the frame, and a headstock 3 and a tailstock 4 arranged side by side on the workbench horizontally, and the headstock is installed horizontally There is the main shaft 5 that can rotate relative to the main shaft box and is hollow, the head and the tail of the main shaft all stretch out of the described main shaft box, and the head of the main shaft is connected with the rotary drive mechanism, and the afterbody of the main shaft is provided with There is a clamping seat 6, the clamping seat is provided with a movable chamber 7, and the outer side of the inner wall of the movable chamber is provided with an extrusion slope 8;

[0022] A top shaft 9 is slid horizontally in the main shaft, a spring 10 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com