Amphibious remote control camera car

A technology for amphibious and camera vehicles, applied in amphibious vehicles, motor vehicles, image communication, etc., can solve the problem of inconvenient shooting and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

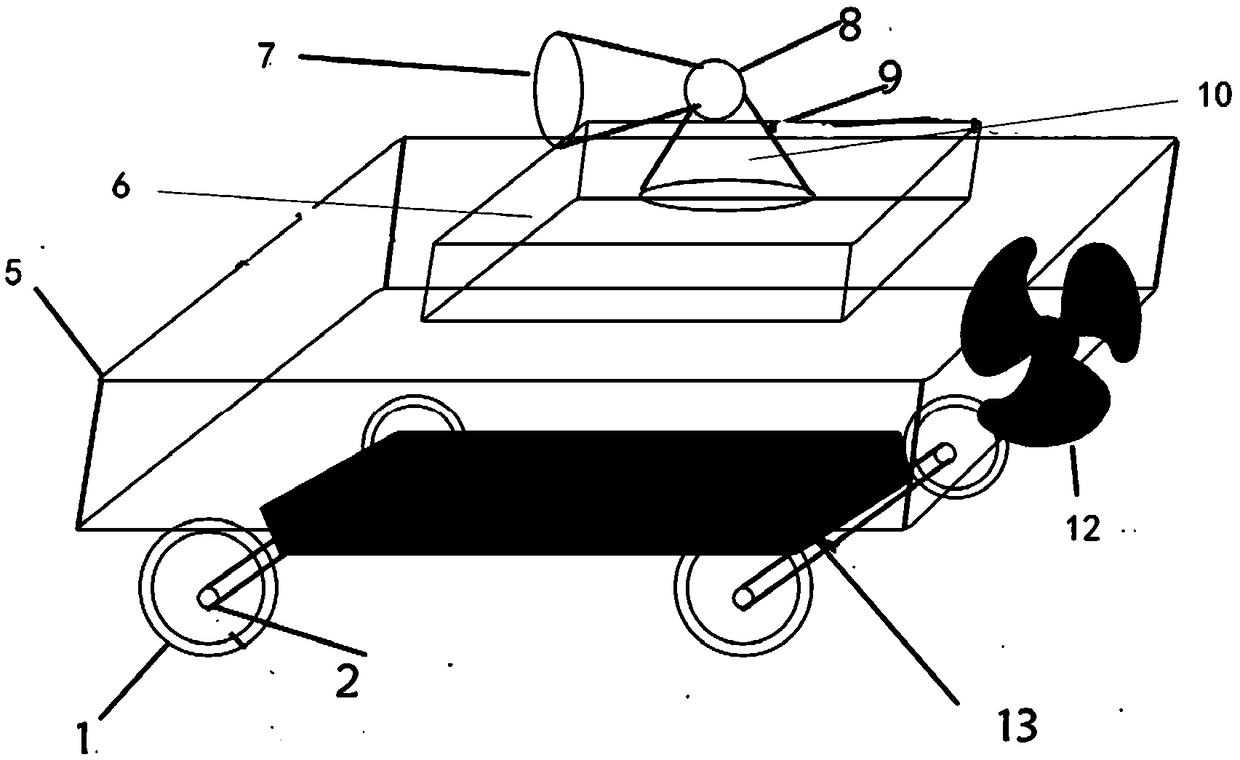

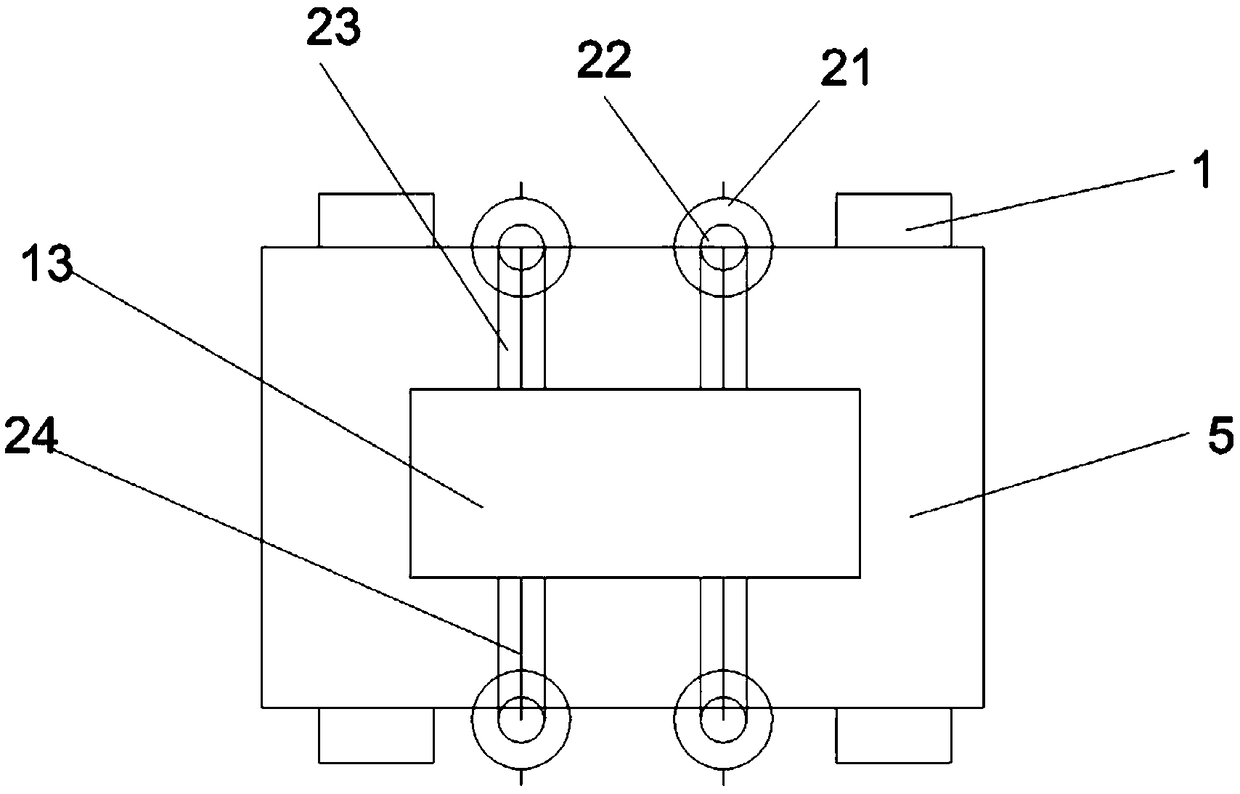

[0013] As shown in the figure, a remote control camera car for amphibious use includes a shock absorbing box 5, tires 1 are installed around the shock absorbing box 5 through bearings 2, and tires 1 are installed on the inner bearings of the tires 1. There is a propeller, and the bearing 2 is driven and rotated by a motor arranged on the shock absorbing box 5, and a passing base 6 is installed on the shock absorbing box 5, and a support 9 is installed on the base 6, and the support 9 A motor two 8 is installed on the motor two 8, and a camera 7 is installed on the motor two 8, and the camera 7 is connected to the video signal transmitter 10 arranged on the frame 9 through a data line, and a power battery is installed inside the shock-absorbing box 5 13. A power supply line group 1 is connected between the power battery 13 and the motor 1, the motor 2 8, the camera 7, and the video signal transmitter 10, and a controller is installed inside the shock-absorbing box 5, and on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap