Four edge overlock machine

A four-sided machine and side-sewing technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problem of sewing pattern collapse and achieve the effect of preventing thread collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

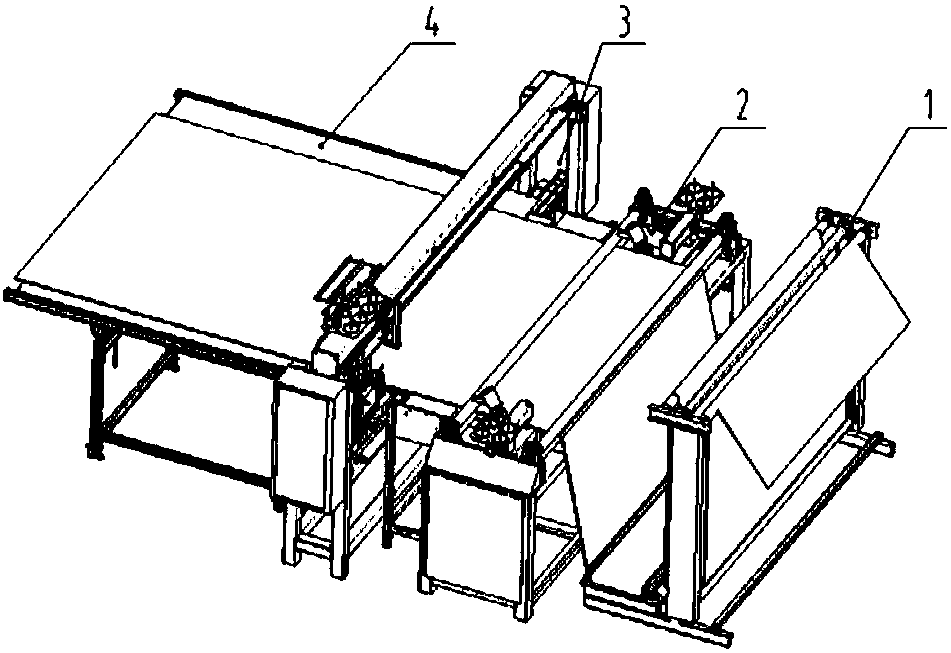

[0009] The following describes the present invention in detail in conjunction with the accompanying drawings. The four-sided lock machine includes a material storage device 1, a side-cutting and side-sewing device 2, a cross-cutting and transverse sewing device 3, and a transmission device 4. The auxiliary materials quilted by the quilting machine enter the lock In the material storage device 1 of the quadrilateral machine, this device is used to connect two machines and store redundant auxiliary materials due to different working efficiencies. When the storage is full or empty, the sensor signal will be triggered to control the quadrilateral machine or quilting machine. Stop and wait, the auxiliary material enters the edge cutting and sewing device 2 for sewing edge creasing, and the sewing machine head performs sewing. There is a cutting knife behind the sewing machine head, which will carry out crimping and edge trimming according to the required margin, and one side of the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com