Construction method for bent cap hoop support integral detachment

A construction method and technology of covering beams, which are applied in building maintenance, construction, building construction, etc., can solve the problems of self-heavy, large span, and difficult construction safety control of support components, so as to improve demolition efficiency, ensure safety, Reduce the effect of high-altitude operations and lifting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0020] A construction method for integrally dismantling the hoop support of the cover beam according to the present invention comprises the following steps:

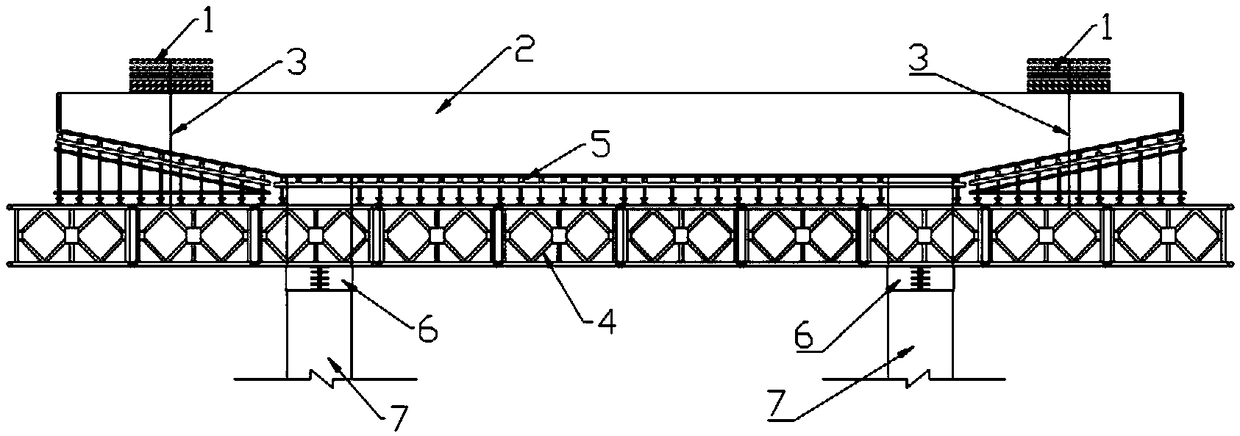

[0021] S1: Install the pressure-bearing device 1: place the pressure-bearing device 1 on the 1 / 2 cantilever position of the cover beam 2 with a crane (not shown in the figure);

[0022] S2: Install the steel wire rope 3: fix one end of the steel wire rope 3 on the upper end of the support 4, and fix the other end of the steel wire rope 3 on the pressure bearing device 1, so as to transmit the pressure of the steel wire rope 3 to the Cover beam 2, and protect with gasket (not shown in the figure) at the angular posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com