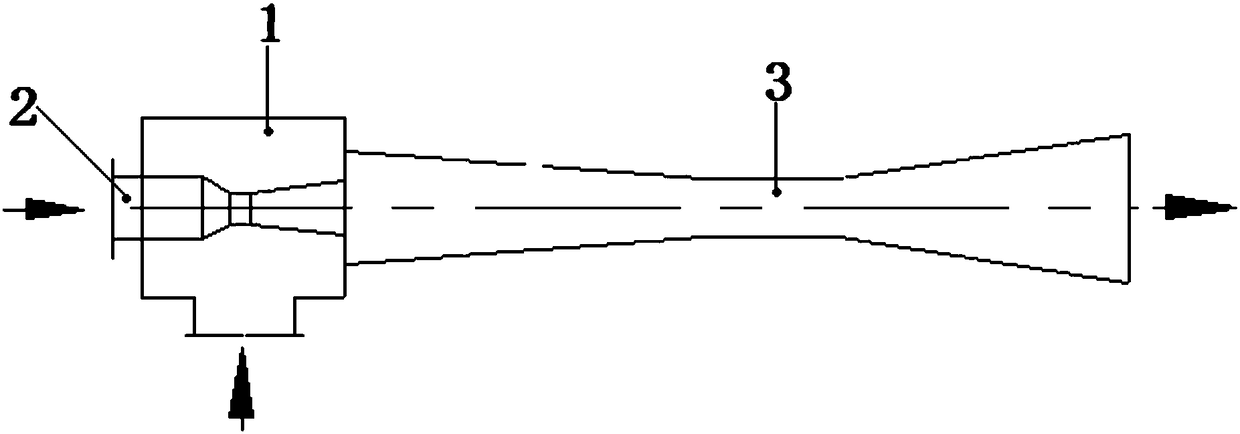

Steam ejector

A technology of ejector and steam, applied in the field of ejector, can solve the problems of high consumption of high-pressure steam, low efficiency of pumping liquid, increase production cost, etc., and achieve the effects of high-efficiency pumping, simple structure and reduced consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

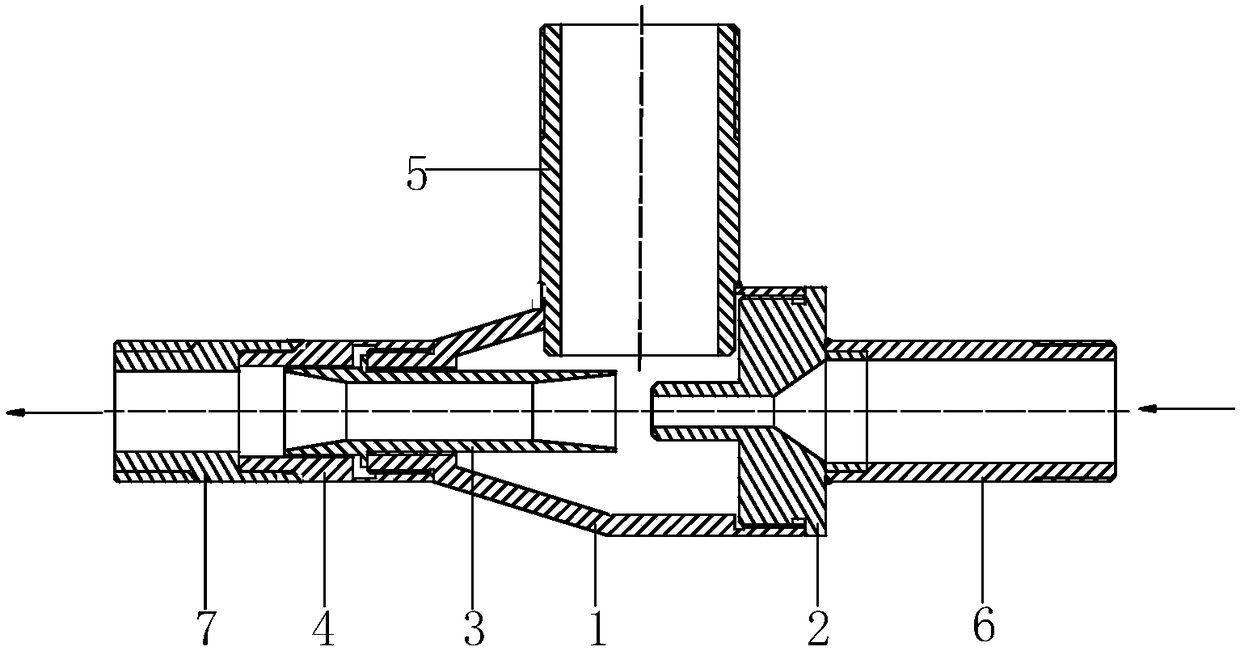

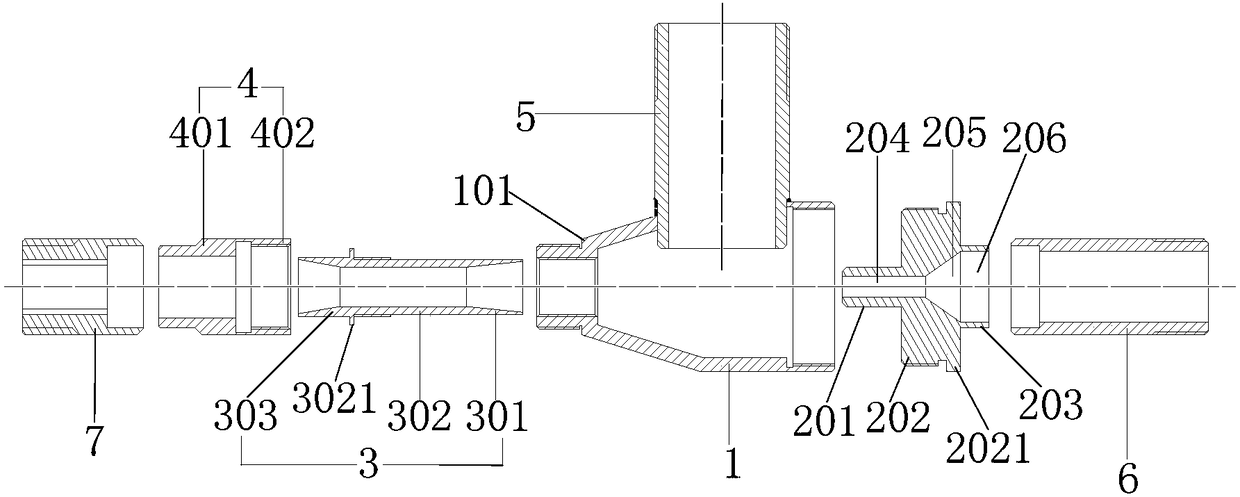

[0054] As a first embodiment: the nozzle 2 is screwed to the steam inlet; the mixing diffuser 3 is screwed to the vapor-liquid outlet.

[0055] The way of screw connection is easy to set up, which is convenient for the disassembly and assembly between the nozzle 2 and the receiving chamber 1 , and between the mixing diffuser pipe 3 and the receiving chamber 1 .

[0056] Specifically, internal threads are provided on the inner wall where the steam inlet and the vapor-liquid outlet of the receiving chamber 1 are located, and the outer walls of the nozzle 2 and the mixing diffuser 3 are provided with internal threads corresponding to the internal threads on the steam inlet and the vapor-liquid outlet. Cooperating external threads are used to facilitate the threaded connection of the nozzle 2, the mixing diffuser 3 and the receiving chamber 1.

[0057] After the nozzle 2, the mixing diffuser 3 are connected to the receiving chamber 1, in order to ensure that the axis of the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com