A testing device and evaluation method for bonding strength of an ultrathin layered metal composite material

A technology of layered metal and composite materials, applied in the direction of measuring device, using stable tension/pressure to test material strength, analyzing materials, etc., can solve the problem of inability to evaluate the bonding strength of layered metal composite materials, and the dimension in the thickness direction does not meet the requirements of preparation Tensile or shear test sample requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention is a testing device for the bonding strength of ultra-thin layered metal composite materials,

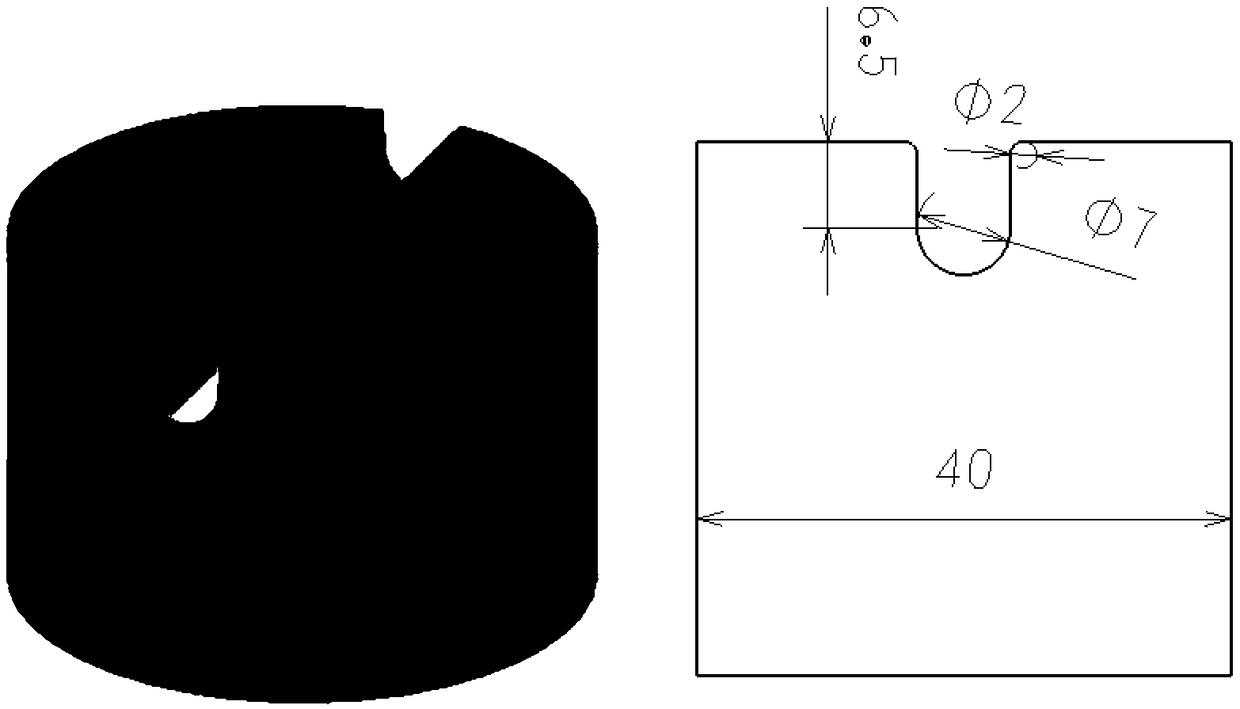

[0038] The width of the groove of the lower mold base is 7mm; the groove depth is 10mm.

[0039] The radius of the arc of the upper edge of the groove of the lower mold base is 1 mm, and the angle of the center of the circle is 90 degrees.

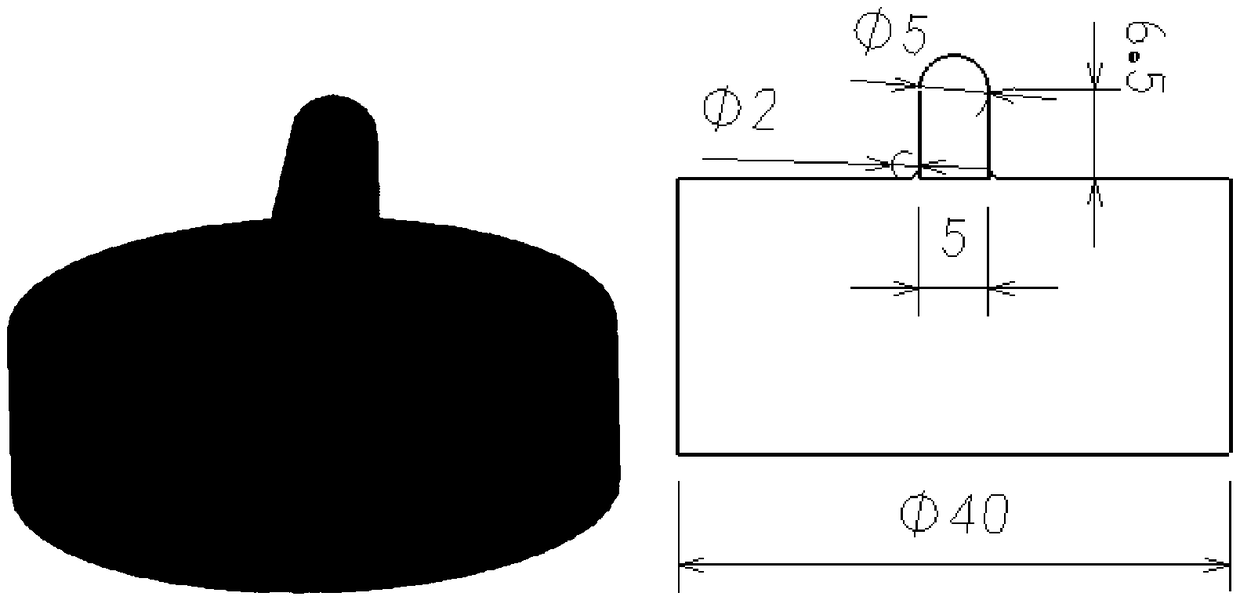

[0040] The raised portion on the upper die punch has a raised height of 9 mm and a width of 5 mm.

[0041] The upper die is punched, and the top of the raised part is arc-shaped; the radius of the arc is 2.5 mm, and the angle of the center of the circle is 180 degrees. The specific dimensions of the test device are as figure 1 figure 2 shown.

[0042] A method for evaluating the bonding strength of ultra-thin layered metal composite materials, the specific steps are as follows:

[0043] (1) Al / Mg layered composites were prepared by hot-pressing diffusion, and the thicknesses of Al and Mg were 0.5 mm and 0.8 mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Center angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com