A strip steel surface defect detection method based on a multi-task scheduling mechanism

A defect detection and multi-task technology, which is applied in the direction of optical defect/defect test, measuring device, material analysis through optical means, etc., can solve the problems of defect accuracy and real-time performance, so as to ensure accuracy and speed, improve The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

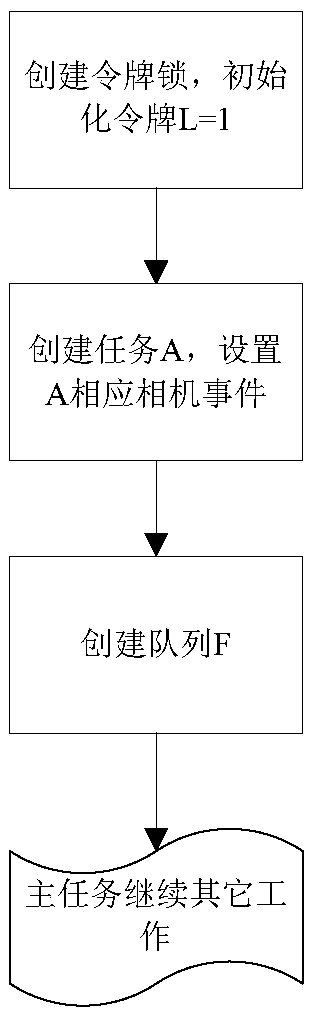

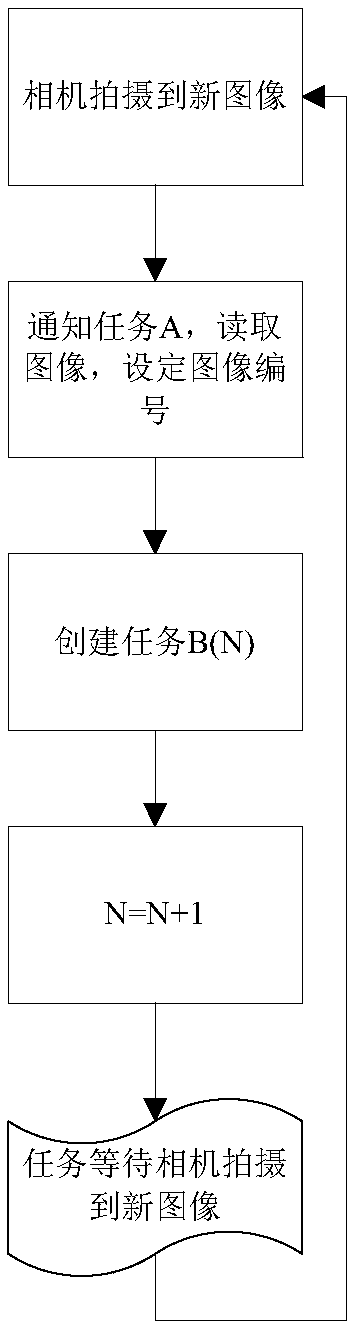

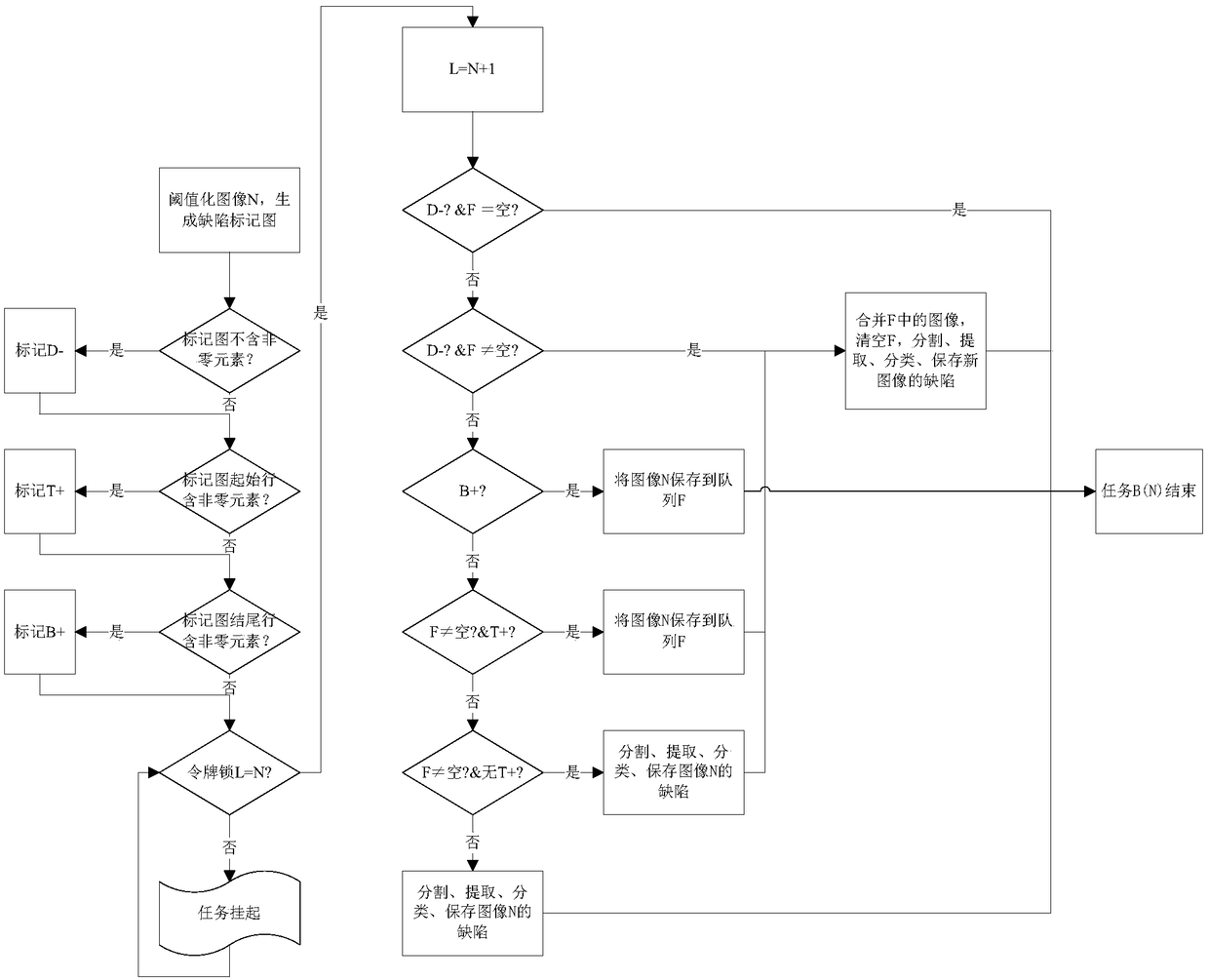

[0044] refer to figure 1 As shown, create a token lock Lock on the main task of the strip steel surface defect detection system, and initialize the token value L of the token lock = 1; create task A on the main task of the strip steel surface defect detection system to respond to the image of the camera Shooting completion event, refer to figure 2 As shown, whenever the camera captures an image, task A reads and collects the strip steel surface image captured by the camera, otherwise task A hangs up and waits, and task A assigns a number N that increases by 1 to the image during execution (the image is named as image N); create a defect cache queue F for storing historical images.

[0045] Create image processing task B (N), begin to carry out the processing operation to image, assign the token of token value N to B (N), N increases by 1 au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com