A method for rapid evaluation of dewatering performance of oxidatively conditioned sludge based on redox potential

A technology for sludge dehydration and dehydration performance, which is applied in the directions of oxidation treatment of sludge, dehydration/drying/thickened sludge treatment, and electrochemical variables of materials, which can solve the problems of poor repeatability of experimental data, complicated operation, and long time consumption, etc., and achieve The sampling process is simple and easy, the operation is simple, and the effect of requiring less samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

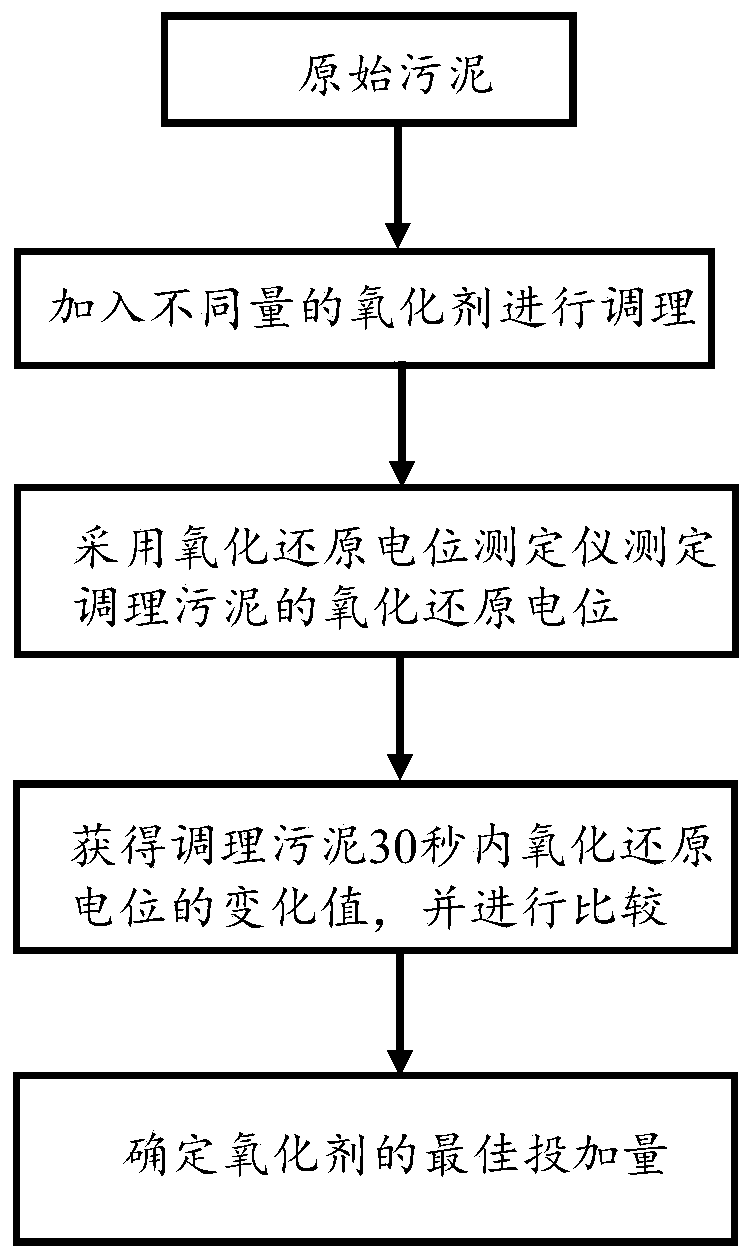

[0052] In this embodiment, based on the oxidation-reduction potential (ORP), the dehydration performance of the same oxidant with different concentrations of sludge is quickly compared and evaluated, and the following steps are carried out:

[0053] (1) The sludge in this example is taken from the thickening tank of Shahu Sewage Treatment Plant in Wuhan. Sludge samples were collected and transported back in polypropylene buckets. The sludge was pre-filtered through a 1mm standard sieve to remove large sand and gravel, and stored in a 4°C freezer. Since the sludge is perishable, the experiments were completed within 3 days after the sludge was collected;

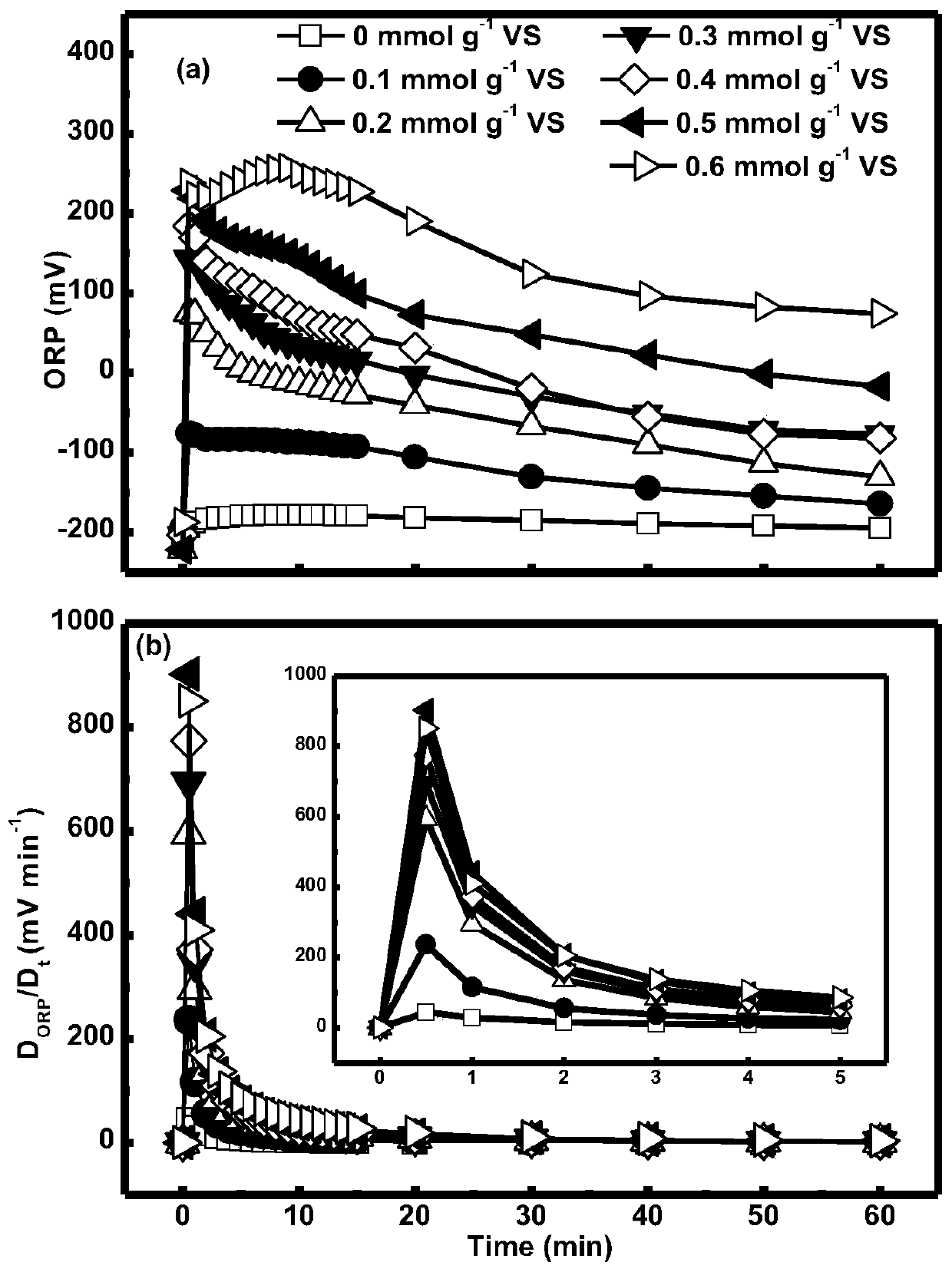

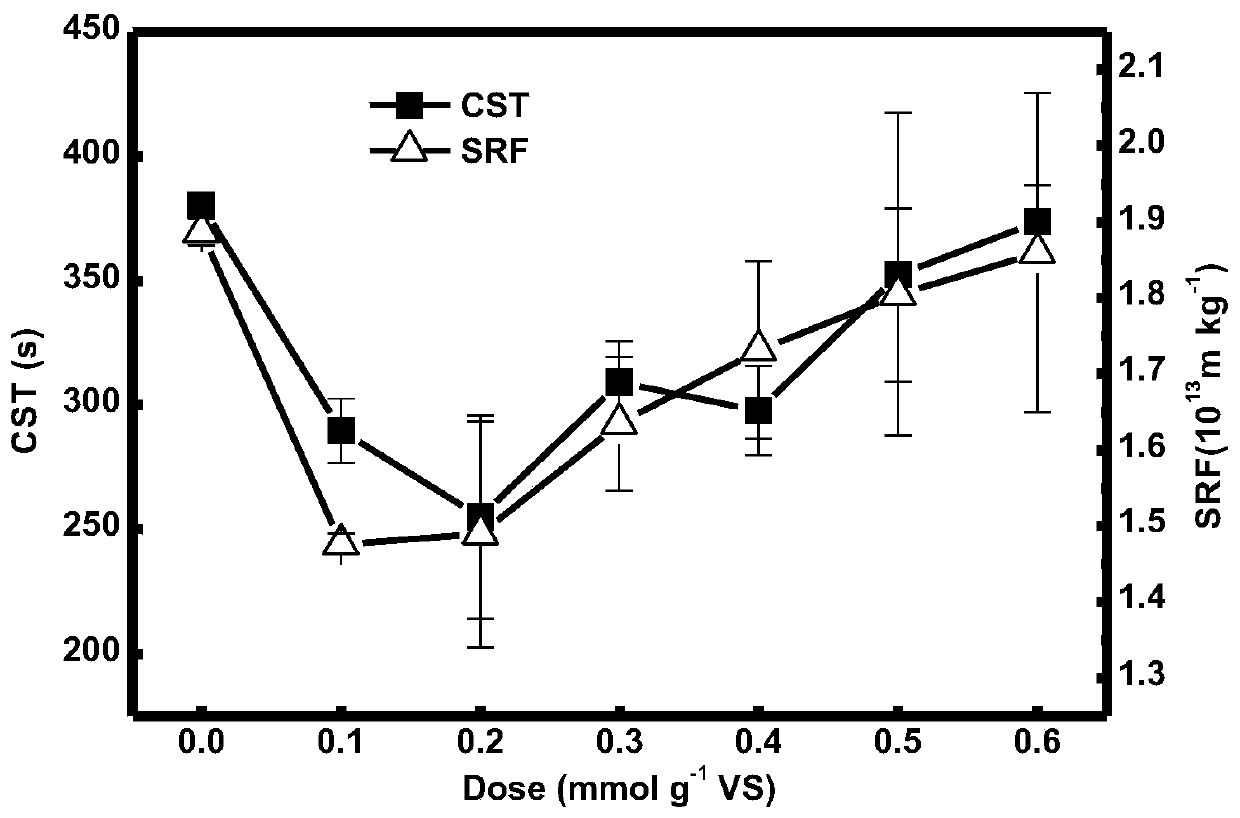

[0054] (2) Take 40mL of raw mud in a 50mL centrifuge tube, add 0.1-0.6mmol g -1 VS Potassium persulfate compound salt (Oxone), oscillated at 150rpm in a horizontal shaker for 20min;

[0055] (3) Measure the change of ORP within 30 seconds in the process of conditioning sludge with different concentrations of Oxone;

[005...

Embodiment 2

[0059] In this example, based on the oxidation-reduction potential (ORP), the dehydration performance of different oxidants with the same concentration of sludge is quickly compared and evaluated, and the following steps are carried out:

[0060] (1) The sludge in this example is taken from the thickening tank of Shahu Sewage Treatment Plant in Wuhan. Sludge samples were collected and transported back in polypropylene buckets. Filter out large sand and gravel through a 1mm standard sieve, and store in a 4°C freezer. Since the sludge is perishable, the experiments were completed within 3 days after the sludge was collected;

[0061] (2) Pour 10kg of sludge into the sludge conditioning tank first, and add 0.9mmol g -1 VS potassium persulfate (K 2 S 2 o 8 ), potassium persulfate compound salt (Oxone) and hydrogen peroxide (H 2 o 2 ), let the conditioning agent and the sludge fully mix and react for 20 minutes. At the same time, the change value of ORP within 30 seconds is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com