A method for screening flavored milk powder formula

A technology for flavored milk and formula, applied in dairy products, milk preparations, testing dairy products, etc., can solve the problems of prolonged research and development time, uneven tissue state, and increased research and development costs, so as to reduce the deviation of production experience and quickly screen formulas , the effect of reducing adverse losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

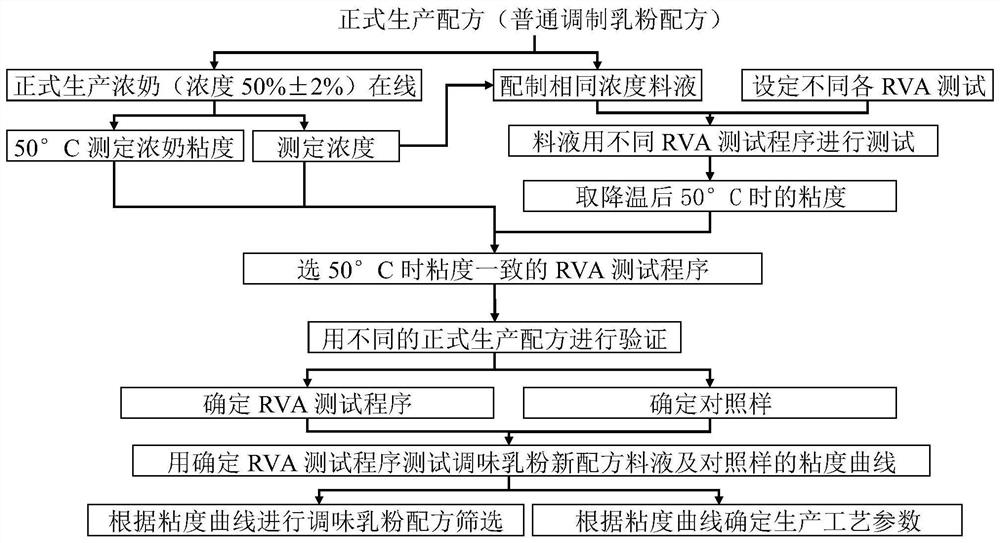

Method used

Image

Examples

Embodiment 1

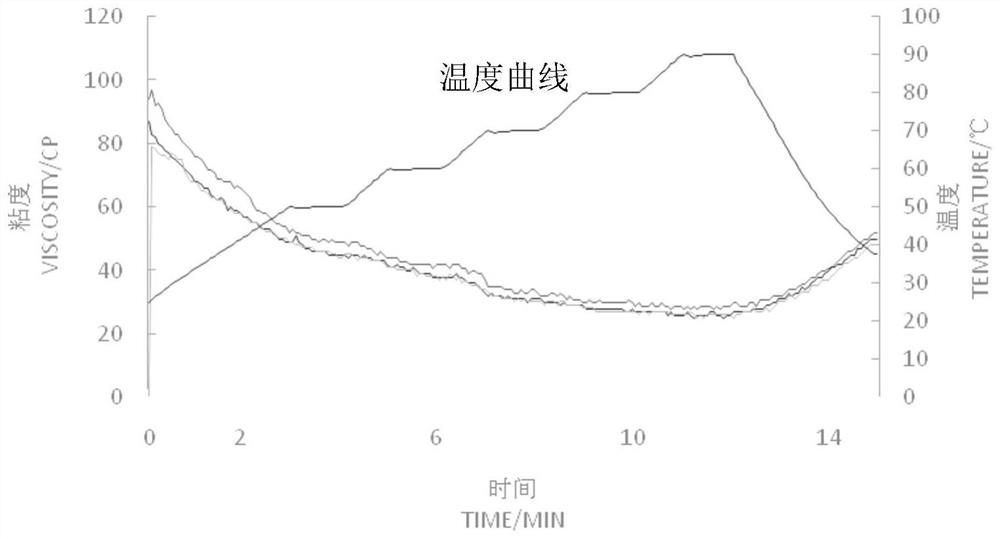

[0041] Refer to the condition that the sterilization and first-effect evaporative concentration temperature is 90°C and the final-effect evaporative concentration temperature is 50°C in the actual production of a common modulated milk powder with high viscosity. A number of different RVA programs are pre-set from 25°C to 90°C in stages and then down to 25°C.

[0042] Through on-line sampling in the actual production of the ordinary modulated milk powder, the concentration and viscosity after final effect evaporation and concentration are measured, and then the same formula is used to prepare the liquid with the same concentration, and the viscosity curve is measured with different RVA test procedures that have been preset. Compare the viscosity at 50°C after cooling down with the viscosity measured at 50°C by online sampling, and determine that the RVA program whose difference between the two is within the range of ±2cP is the pre-used RVA program, and then select other formall...

Embodiment 2

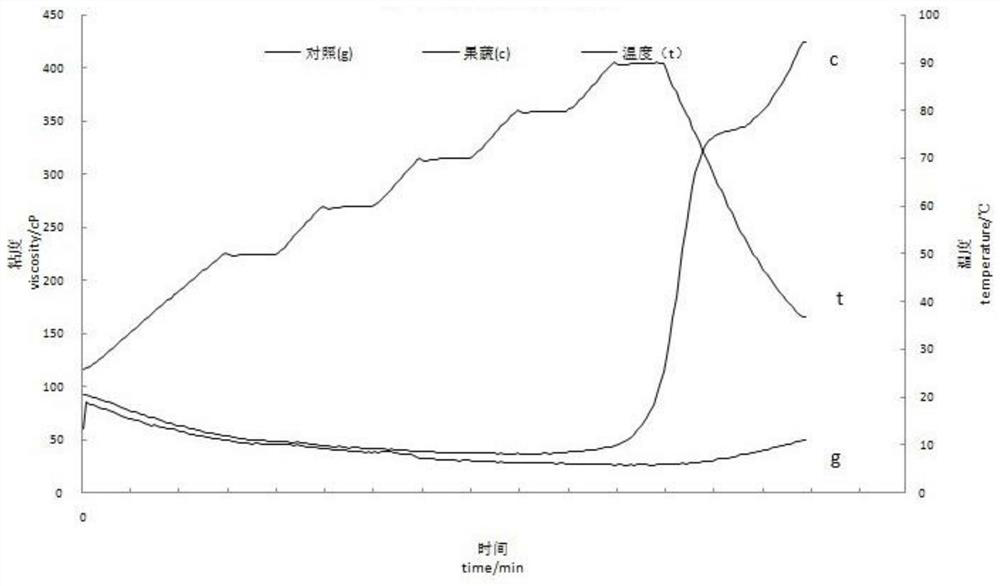

[0045] Pre-produced flavored milk powder formula: a certain viscosity-higher common modulated milk powder+fruit and vegetable powder (carrot powder, pineapple powder, mango powder, banana powder) in embodiment 1;

[0046] Prepare the flavored milk powder formula of pre-production and the common modulated milk powder feed liquid (as a contrast) with certain viscosity higher in embodiment 1, carry out viscosity curve analysis according to the RVA procedure of embodiment 1, the results are shown in image 3 .

[0047] From image 3 It can be seen that the viscosity of the batching solution added with fruit and vegetable powder at the same milk concentration is significantly higher than that of the control solution after heating, especially when the sterilization temperature is 90°C, there is a sharp increase (the slope is significantly higher than the slope of the viscosity curve of the control). Recipe adjusted.

Embodiment 3

[0049] 1. Analyze and determine the main material components that cause the viscosity increase

[0050] Contrast modulated milk powder formula: a common modulated milk powder with higher viscosity in Example 1;

[0051] Flavor substance analysis Flavored milk powder formula: Example 1 common modulated milk powder with higher viscosity + carrot powder; Example 1 common modulated milk powder with higher viscosity + mango powder; Example 1 common modulated milk powder with higher viscosity Milk powder+banana powder; common modulation milk powder+pineapple powder with higher viscosity of embodiment 1;

[0052] Prepare above-mentioned each prescription feed liquid, carry out viscosity curve analysis according to the RVA program of embodiment 1, the results are shown in Figure 4 .

[0053] From Figure 4 It can be seen that compared with the viscosity of the control milk powder without fruit and vegetable powder (a), the viscosity of the feed liquid added with carrot powder (b),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com