Feed granulator and operation method thereof

A granulator and feed technology, applied in feed, chemical instruments and methods, solid separation, etc., can solve the problems of unstable feed to the granulator and coarse particle size of incoming raw materials, so as to achieve stable incoming materials and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

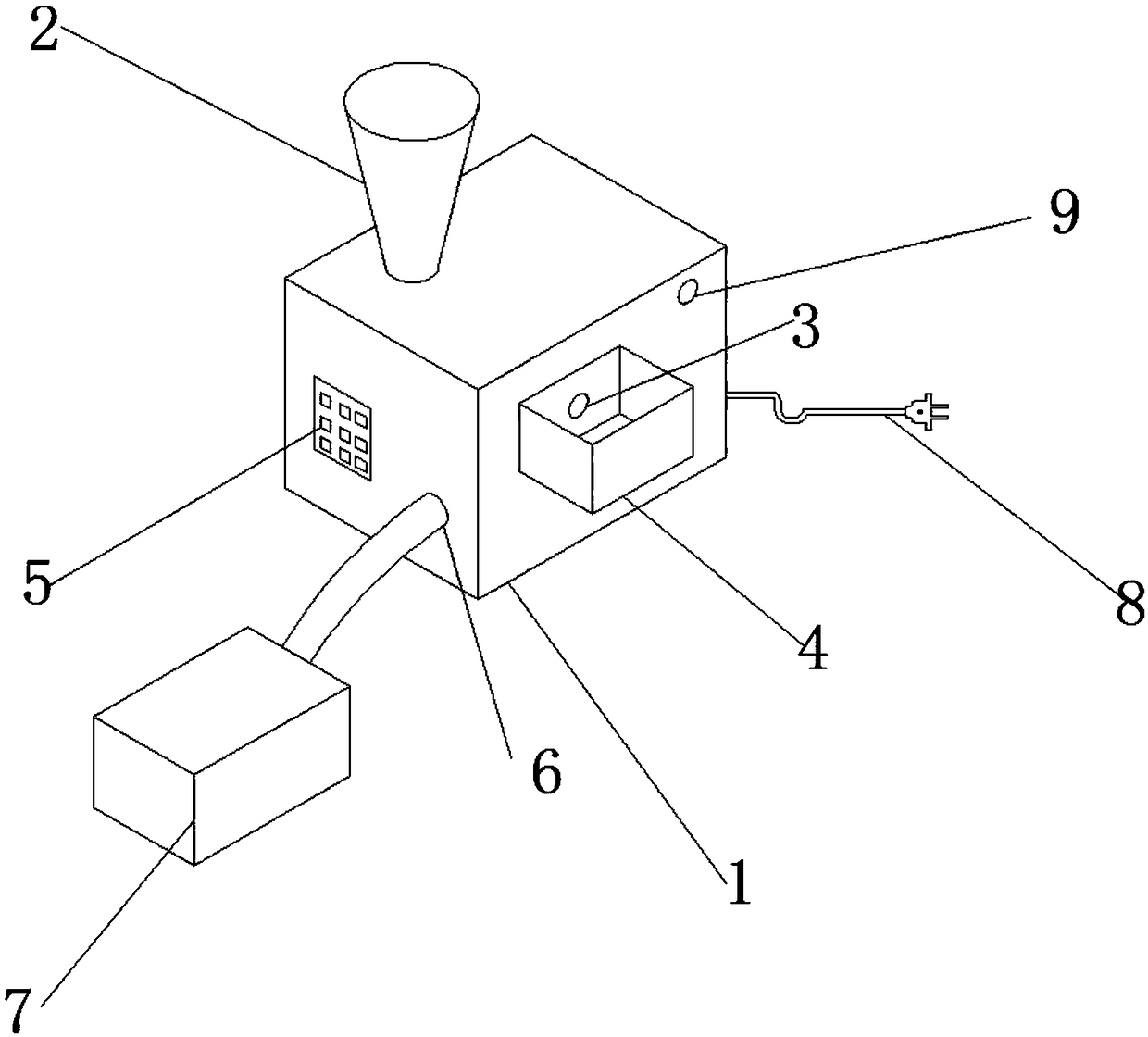

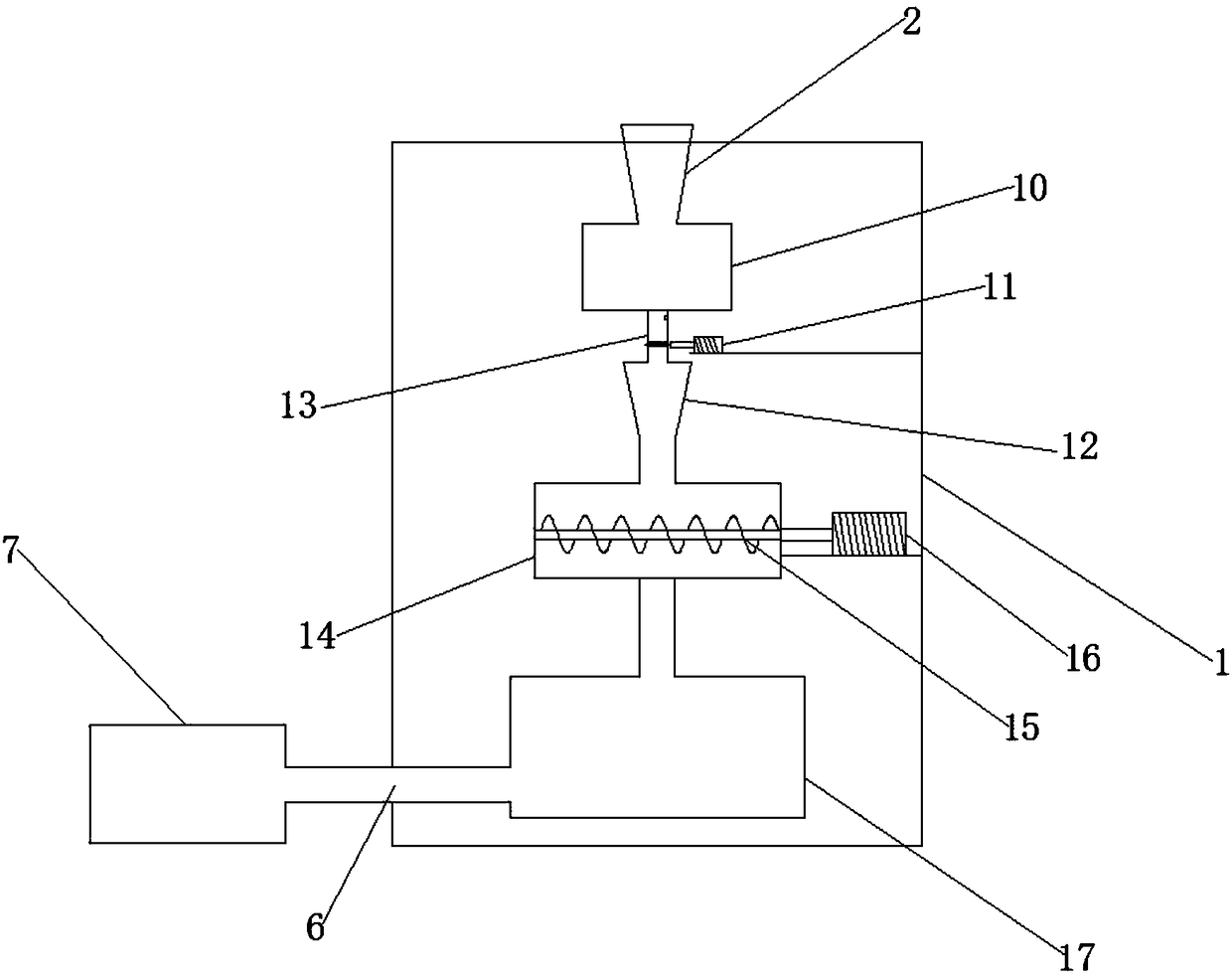

[0018] The present invention proposes a feed granulator, comprising a body 1, a feeder 10 is provided at the top of the body 1, the bottom of the feeder 10 is connected to a buffer bin 12 through a feeding pipeline 13, and the bottom of the buffer bin 12 is A conditioner 14 is provided directly below, and the bottom of the conditioner 14 is connected to the feed port of the granulation device 17 through a pipeline. The discharge port 6 is connected with the cooler 7 through a pipe, the body 1 is connected with a power plug 8 , and the outer surface of the body 1 is provided with a control panel 5 .

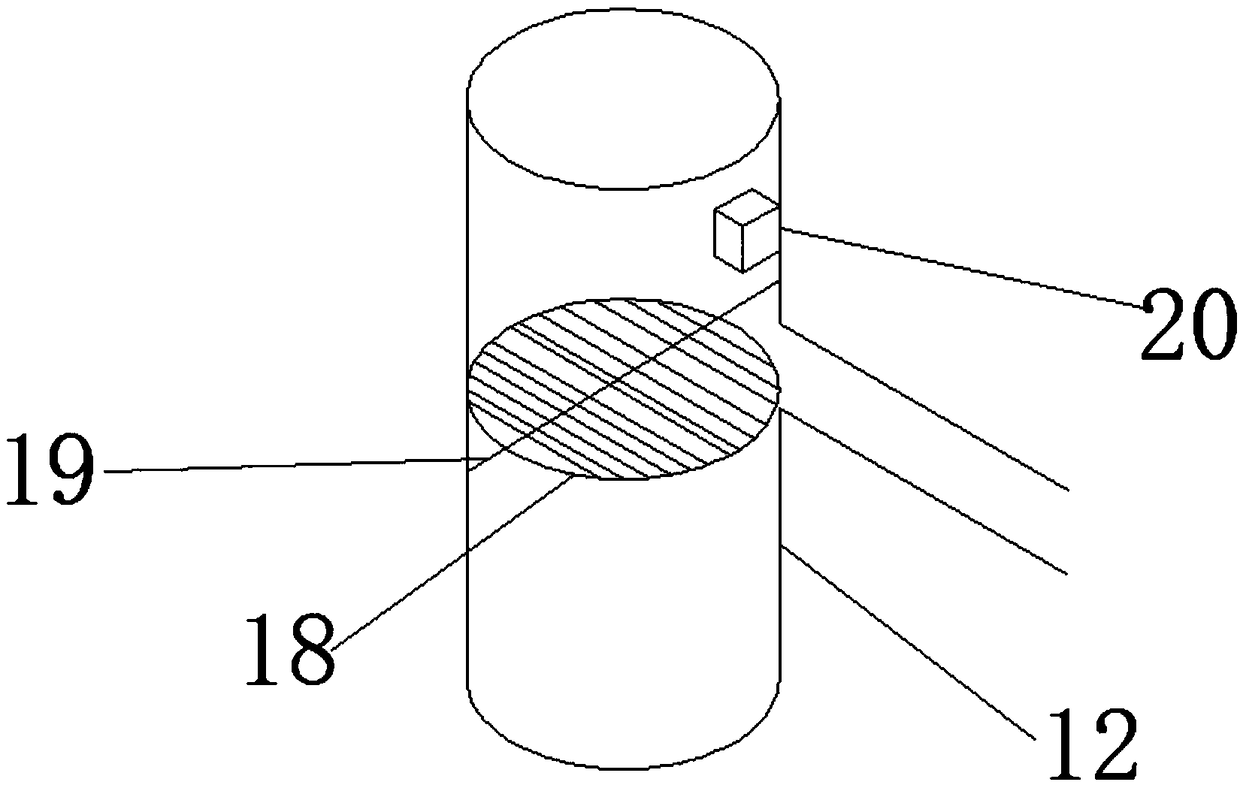

[0019] A feeding funnel 2 is provided at the connection between th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap